ROYAL ENFIELD UCE ENGINE SERVICE MANUAL

2

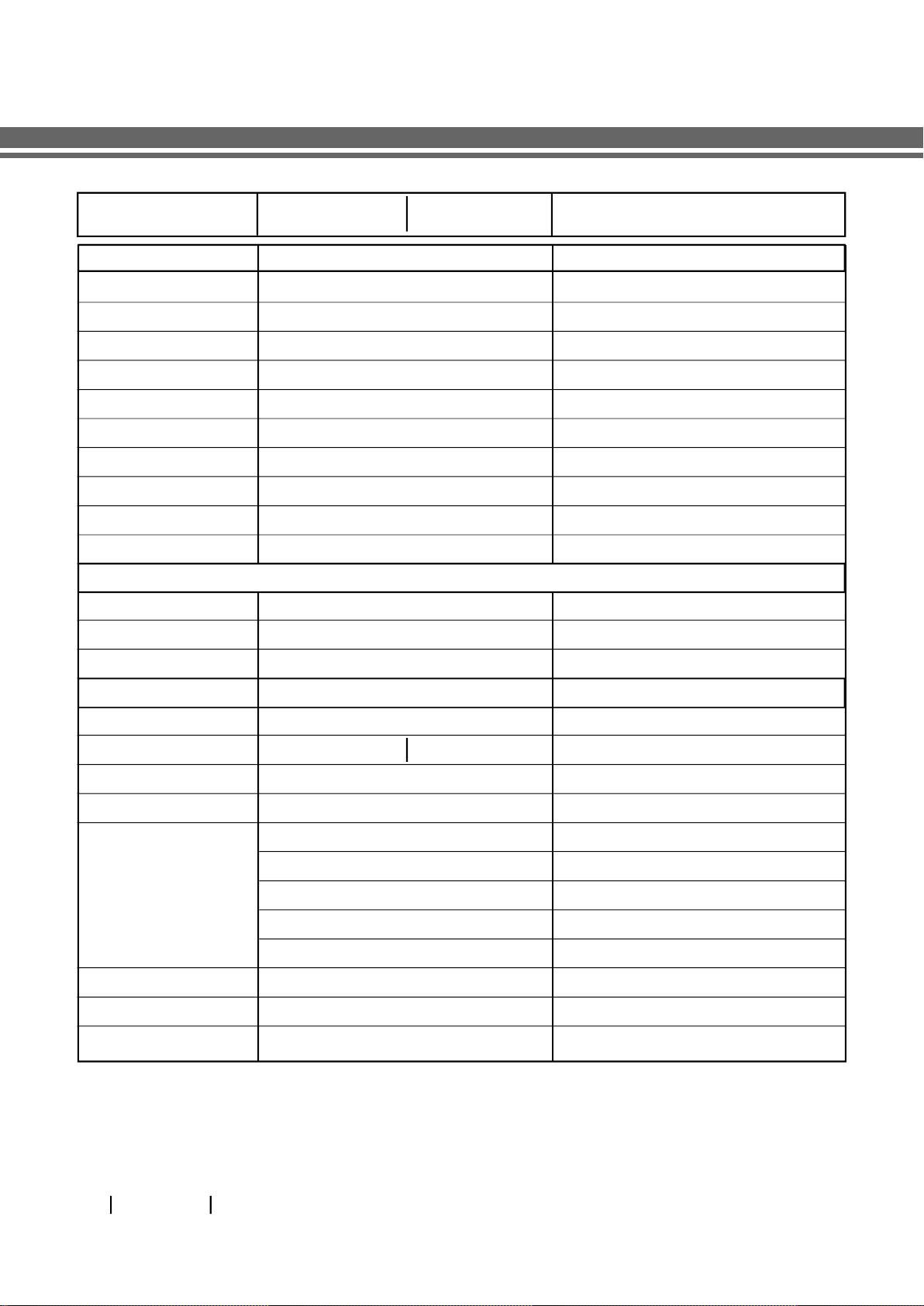

CONTENTS

ROYAL ENFIELD UCE ENGINE SERVICE MANUAL

02

1. Engine views ............................................................................ 3

2. Technical Specifications .........................................................4

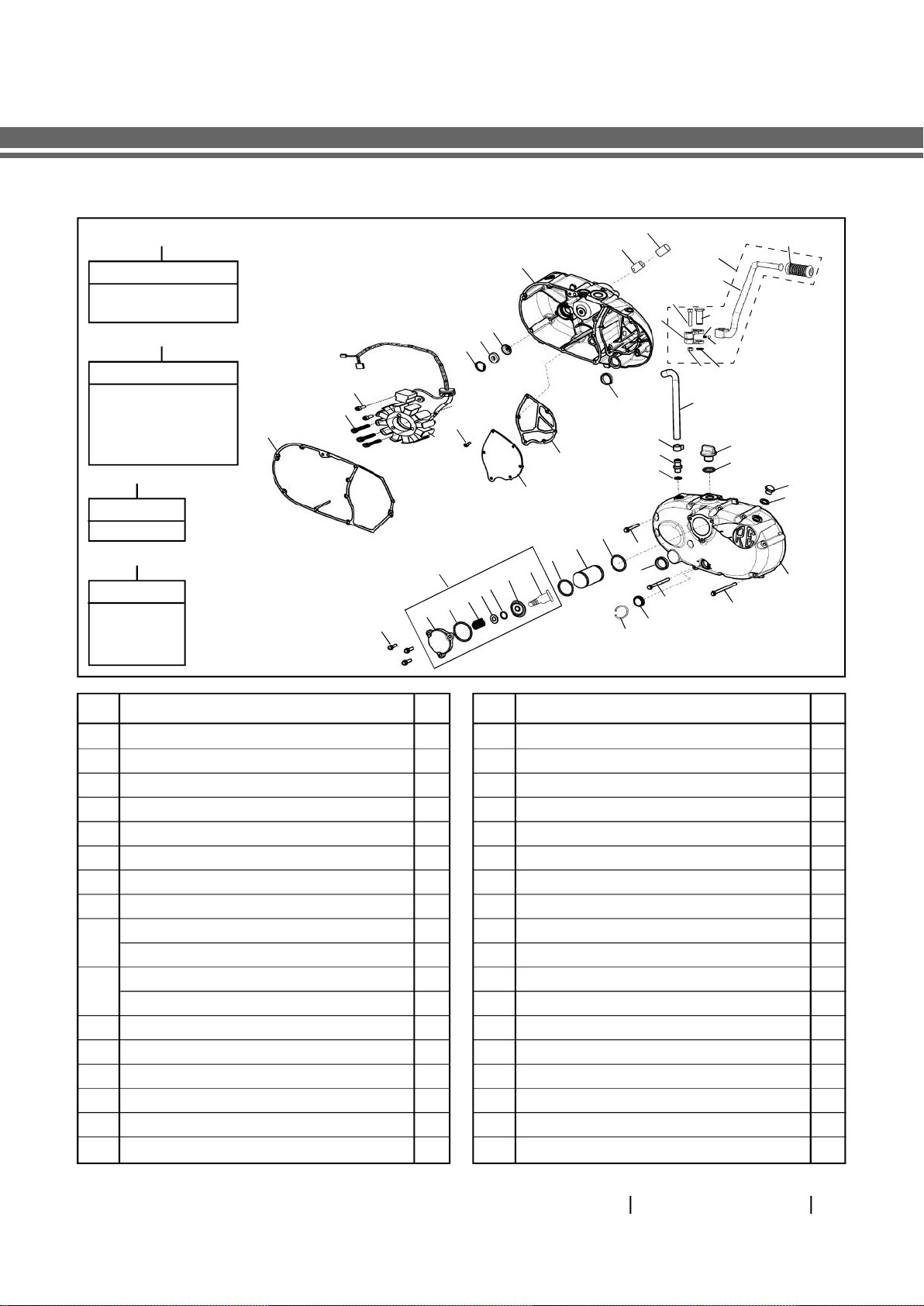

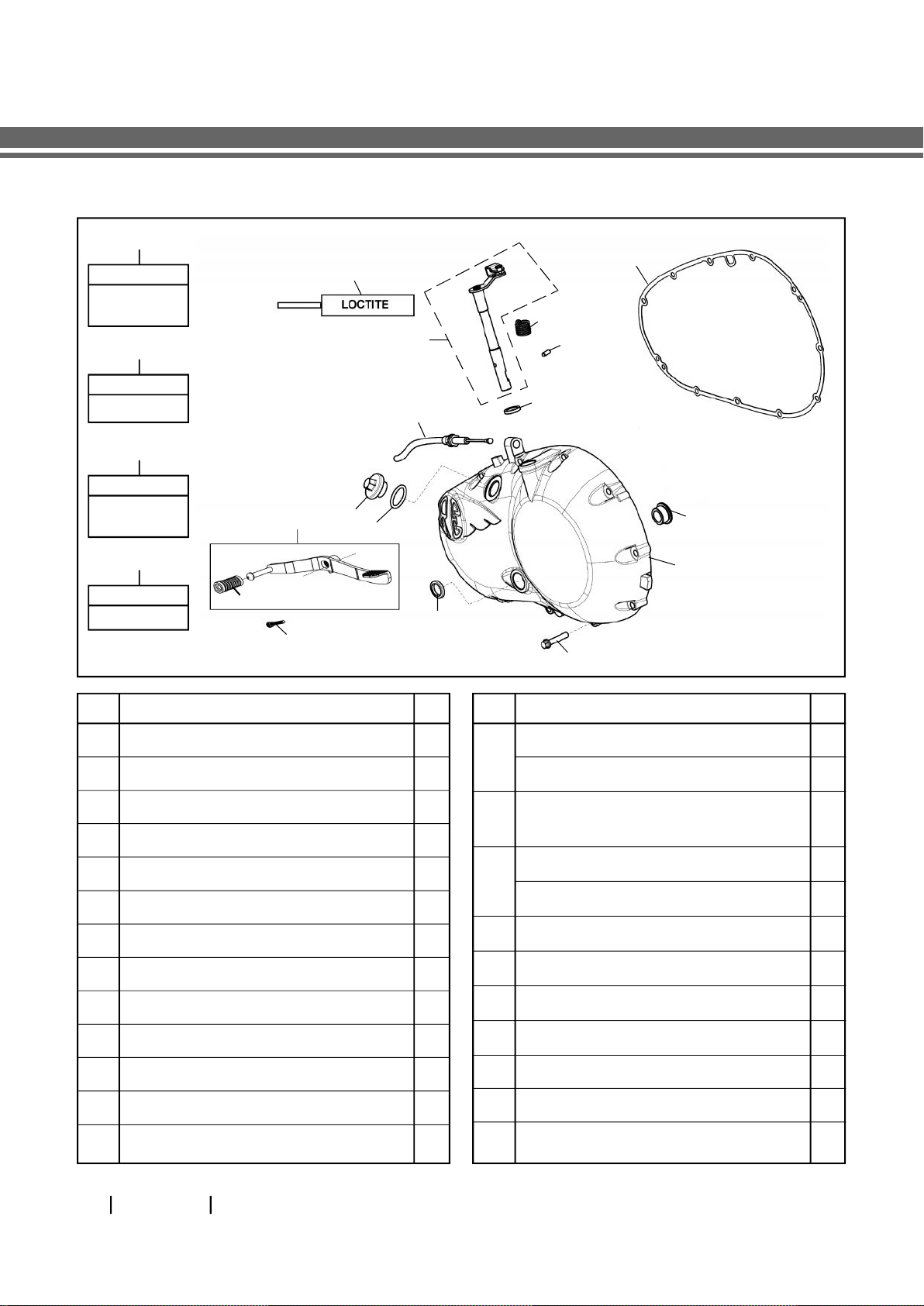

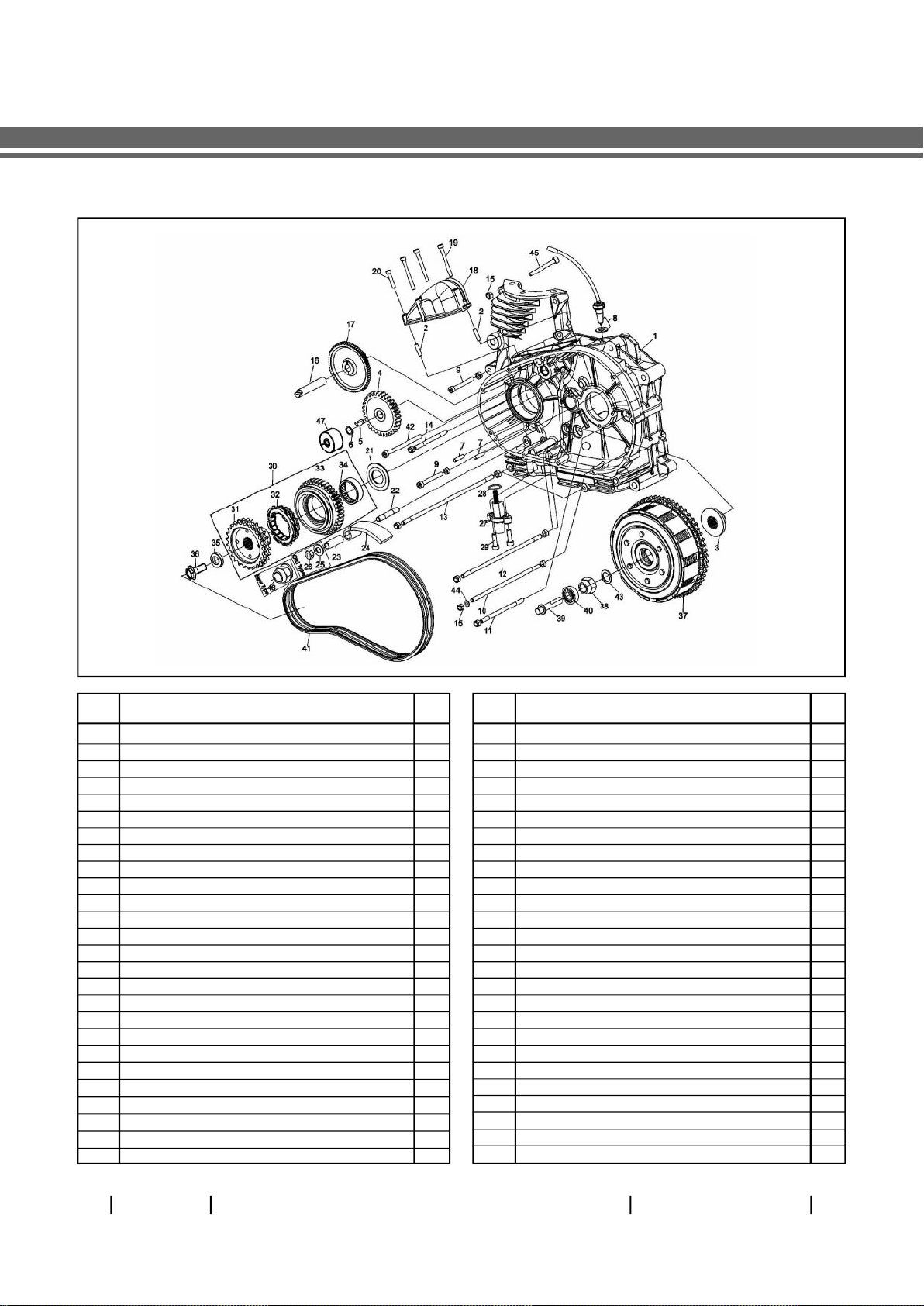

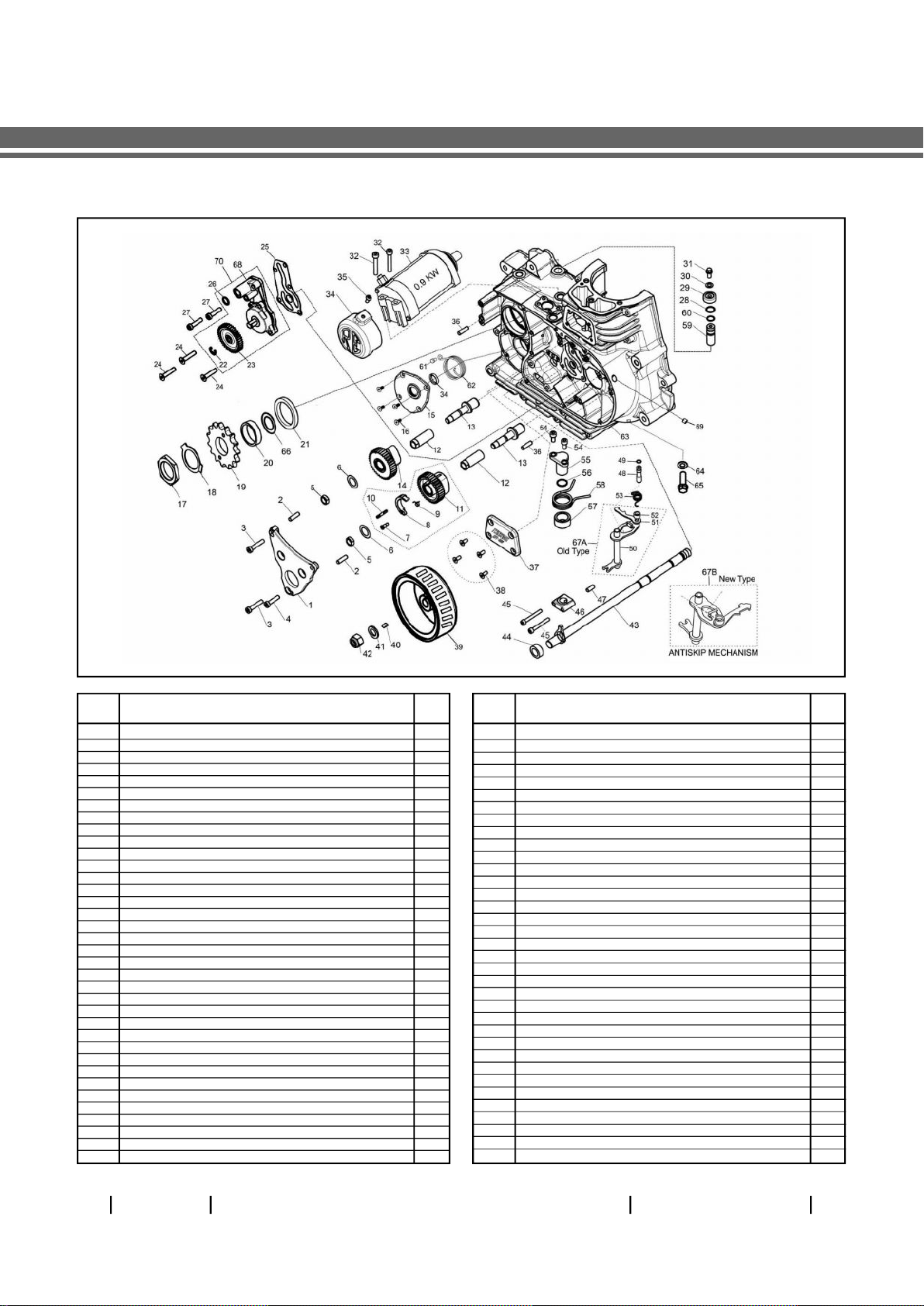

3. Exploded Views ....................................................................... 5

4. Gear Operating Positions .....................................................10

5. Lubrication System ................................................................ 11

6. Periodical Maintenance Chart ..............................................13

7. Special Tools Usage List ........................................................ 14

8. Engine Dismantling Sequence .............................................15

8.1 Engine oil Drain ........................................................... 16

8.2 Cylinder Head ...............................................................17

8.3 Dismantling Inlet & Exhaust Valves .......................... 19

8.4 Cylinder barrel / piston ............................................. 20

8.5 Starter motor & housing ............................................22

8.6 Removal of RH Cover .................................................23

8.7 Removal of Rotor Assembly ...................................... 27

8.8 Cam steady plate & cam gears .................................. 28

8.9 Auto Decompressor .................................................. 29

8.10 Oil Pump ..................................................................... 30

8.11 Gear Shift assembly removal ......................................31

8.12 F.D. Sprocket ................................................................ 33

8.13 Kick Starter ...................................................................35

8.14 Cover LH ...................................................................... 36

8.15 Clutch Assembly ........................................................ 38

8.16 Sprag Clutch Assembly ............................................. 40

8.17 Dismantling of Clutch Assembly .............................. 41

8.18 Auto Chain Tensioner ............................................... 43

8.19 Starter Double Gear ................................................... 44

8.20 Crankcase LH & RH..................................................... 45

8.21 Gear Train Removal ................................................... 50

8.22 Hydraulic Tappets ....................................................... 53

8.23 Layshaft ...................................................................... 54

8.24 Mainshaft.....................................................................55

8.25 Sleeve Gear ..................................................................57

8.26 Kick Starter .................................................................. 58

8.27 Kick Starter Shaft ........................................................ 59

9. Uni Directional Fittings List .................................................. 61

10.Inspection ............................................................................. 62

11. Torque Chart ......................................................................... 78

12. Engine Assembling Sequence ............................................80

12.1 Engine Bearings Crankcase LH .................................. 81

12.2 Engine Bearings Crankcase RH................................. 83

12.3 Kick Starter sub Assembly ........................................ 85

12.4 Kick Starter shaft ........................................................ 86

12.5 Layshaft Sub Assembly ............................................. 88

12.6 Mainshaft Sub Assembly .......................................... 90

12.7 Hydraulic Tappets ...................................................... 98

12.8 Drain Plug ................................................................. 100

12.9 Gear Train................................................................... 101

12.10 Gear Rocker Shaft on Crankcase RH outer .............102

12.11 Crankcase LH & RH ....................................................105

12.12 Starter Double Gear ................................................. 108

12.13 Auto Chain Tensioner ............................................. 109

12.14 Sprag Clutch Assembly ............................................ 110

12.15 Sub Assembly of Clutch Plates .................................. 111

12.16 Assembly of Clutch ................................................... 113

12.17 Cover LH ...................................................................... 115

12.18 FD Sprocket ................................................................118

12.19 Gear Shift Assembly .................................................. 119

12.20 Oil Pump ....................................................................120

12.21 Auto Decompressor .................................................. 121

12.22 Assembly Procedure of Cam Gears .......................... 122

12.23 Assembly of Rotor Assembly .................................. 128

12.24 Assembly of RH Cover ............................................... 131

12.25 Starter motor & housing .......................................... 133

12.26 Cylinder Barrel/Pistion ............................................. 134

12.27 Piston Ring Sub Assembly ....................................... 135

12.28 Assembly of Inlet /Exhaust Valves.......................... 136

12.29 Cylinder Head Assembly.......................................... 138

12.30 Engine Oil Filling ...................................................... 140

13. Trouble Shooting .................................................................141

SL.NO. DESCRIPTION PG.NO. SL.NO. DESCRIPTION PG.NO.