2

Table of Contents

Chapter 0 Preface..................................................................4

0.1 Preface...................................................................................................................4

Chapter 1 Safety Precautions ......................................................5

1.1 Before Power Up ....................................................................................................5

1.2 During Power Up ...................................................................................................6

1.3 Before Operation ...................................................................................................6

1.4 During Operation ...................................................................................................7

1.5 Inverter Disposal.....................................................................................................7

Chapter 2 Part Number Definition ..................................................8

2.1 Model part number..................................................................................................8

Chapter 3 Environment & Installation ................................................

3.1 Environment..............................................................................................................

3.1.1 Wiring and EMC guidelines....................................................... 9

3.1.2 Considerations for peripheral equipment ................................ 11

3.2 Specifications …………………………………………………………………………...10

3.2.1 Product Specifications ............................................................ 12

3.2.2 General Specifications............................................................ 11

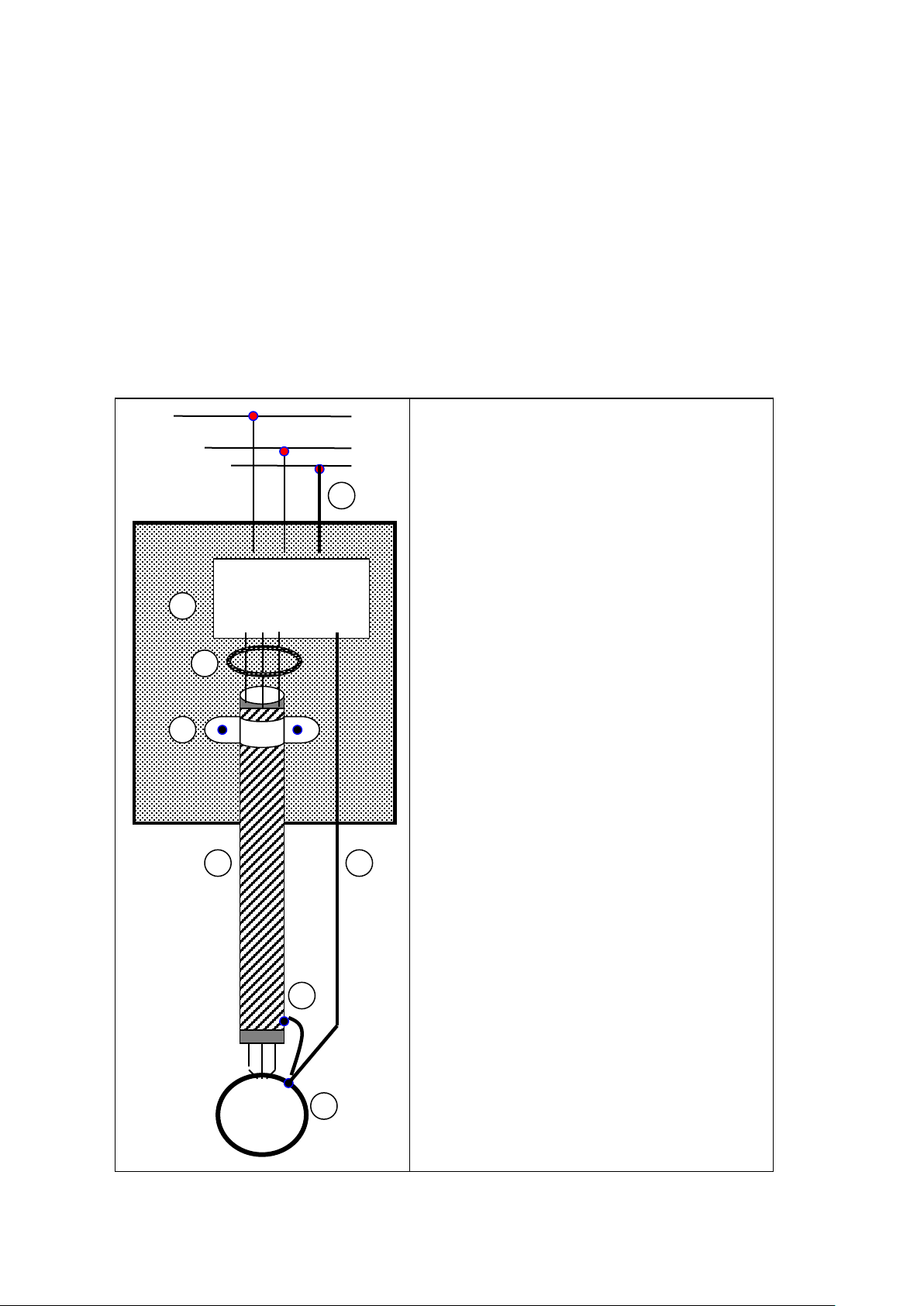

3.3 Standard wiring...................................................................................................153

3.3.1 Single phase(PNP) input…………………………………….……13

3.3.2 Three phase (PNP)input…………………………………………..14

3.3.3 NPN/PNP selectable models……………………………………..15

3.4 Terminal Description...........................................................................................166

3.4.1 Description of main circuit terminals ..................................... 186

3.4.2 Description of control circuit terminals..................................... 18

3.5 Outline Dimensions(unit: mm)...............................................................................18

Chapter4 Software Index.......................................................232

4.1 Keypad Description...............................................................................................24

4.1.1 Operator Panel Functions....................................................... 24

4.2 Programmable Parameter Groups........................................................................25

Chapter 5 Troubleshooting and maintenance ....................................40

5.1 Error display and corrective action........................................................................40

5.1.1 Manual Reset and Auto-Reset................................................ 40

5.1.2 Keypad Operation Error Instruction......................................... 43

5.1.3 Special conditions................................................................... 44

5.2 General troubleshooting .......................................................................................45