ClimateMaster HCLA2090CAR User manual

92-106595-02-00

3

8/OLVWLQJDQG&6$FHUWLILFDWLRQRQVRPHPRGHOVLVLQSURFHVV

&RQWDFW\RXUGLVWULEXWRUIRUDYDLODEOHPRGHOV

INSTALLATION INSTRUCTIONS

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED,

LICENSED SERVICE PERSONNEL FOR PROPER INSTALLATION,

ADJUSTMENT AND OPERATION OF THIS UNIT. READ THESE

INSTRUCTIONS THOROUGHLY BEFORE ATTEMPTING INSTALLA-

TION OR OPERATION. FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SER-

VICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRI-

CAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

DO NOT DESTROY

PLEASE READ CAREFULLY AND KEEP IN A

SAFE PLACE FOR FUTURE REFERENCE.

5HFRJQL]HWKLVV\PERODVDQLQGLFDWLRQRI,PSRUWDQW6DIHW\,QIRUPDWLRQ

!

(-)HGG COMMERCIAL AIR HANDLERS

NOMINAL 7.5 THROUGH 20 TON AIR CONDITIONING

SUPERSEDES 92-42673-01-02 -01-01

INSTALLATION INSTRUCTIONS

RHCL: COMMERCIAL AIR HANDLER WITH VARIABLE

FREQUENCY DRIVE (VFD)

R-410A REFRIGERANT

2-STAGE AIR-FLOW

啌楳瑩湧湤⁃十敲瑩晩捡瑩潮渠獯浥潤敬猠楳渠灲潣敳献

&RQWDFW\RXUGLVWULEXWRUIRUDYDLODEOHPRGHOV

Accredited by the RvA

ISO 9001:2008

Certicate Number: 30164

5HFRJQL]HWKLVV\PERODVDQLQGLFDWLRQRI,PSRUWDQW6DIHW\,QIRUPDWLRQ

!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED,

LICENSED SERVICE PERSONNEL FOR PORPER INSTALLATION,

ADJUSTMENT AND OPERATION OF THIS UNIT. READ THESE

INSTRUCTIONS THOROUGHLY BEFORE ATTEMPTING INSTALLA-

TION OR OPERATION. FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SER-

VICE OR MAINTEMANCE POSSIBLY RESULTING IN FIRE, ELECTRI-

CAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

DO NOT DESTROY

PLEASE READ CAREFULLY AND KEEP IN A

SAFE PLACE FOR FUTURE REFERENCE.

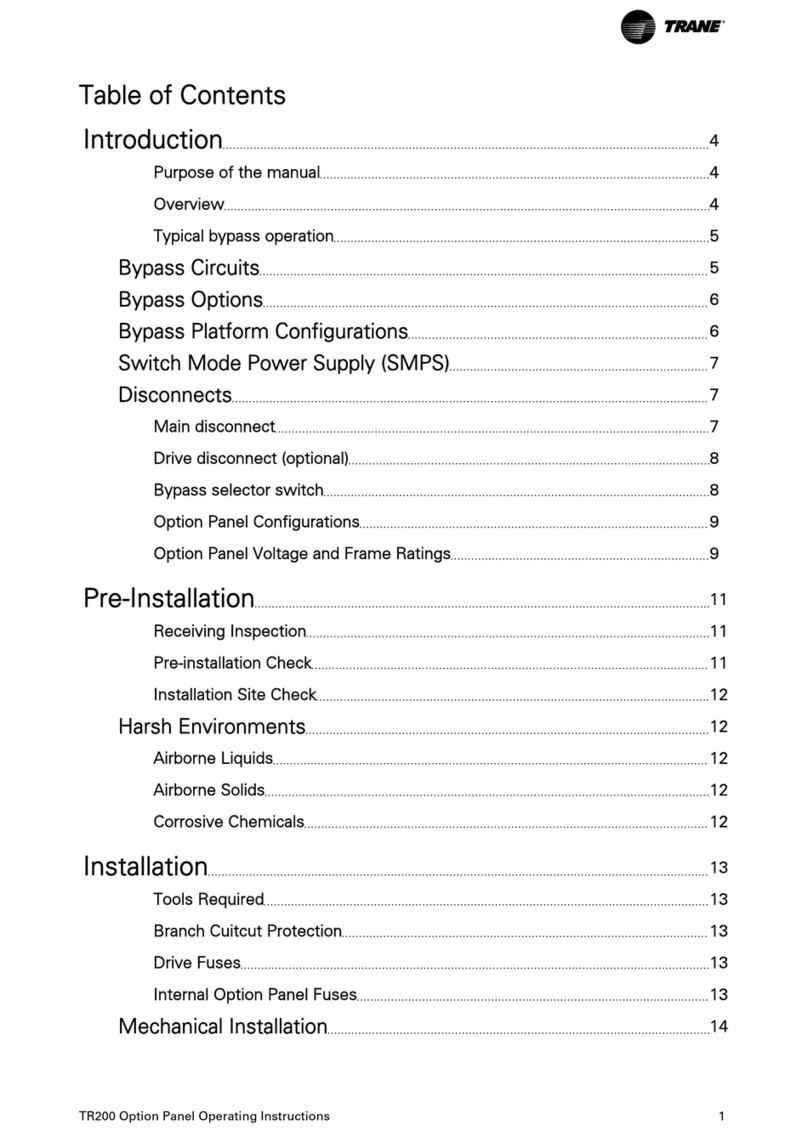

TABLE OF CONTENTS

1.0 Safety Information..................................................................................................... 4

2.0 General Information.................................................................................................. 6

2.1 Important Information About Efciency & Indoor Air Quality................................... 6

2.2 Checking Product Received.................................................................................... 6

2.3 Model Number Nomenclature................................................................................. 6

2.4 Available Models...................................................................................................... 6

2.5 Physical Dimensions - Inches [mm]........................................................................ 7

2.6 Physical Data ......................................................................................................... 9

2.7 Mayor Components................................................................................................. 10

2.8 Importance Of Proper Indoor/Outdoor Match-Ups.................................................. 11

2.9 Importance Of A Quality Installation........................................................................ 11

3.0 Installation................................................................................................................. 12

3.1 Tools & Refrigerant.................................................................................................. 12

3.1.1 Tools Required For Installing And Servicing R-410A Models............................. 12

3.1.2 Specications of R-410A.................................................................................... 12

3.1.3 Quick-Reference Guide for R-410A.................................................................... 12

3.2 Applications & Orientation....................................................................................... 13

3.2.1 Horizontal Discharge.......................................................................................... 13

3.2.2 Vertical Up Discharge......................................................................................... 13

3.2.3 Applications Requiring Electric Heat.................................................................. 14

3.2.4 Suspending Unit................................................................................................ 14

3.2.5 Installation in an Unconditioned Space.............................................................. 14

3.2.6 Installation in Corrosive Environments............................................................... 14

3.3 Auxiliary Overow Pan............................................................................................ 15

3.4 Clearances.............................................................................................................. 15

3.5 Ductwork................................................................................................................. 15

3.6 Return Air Filters..................................................................................................... 15

3.7 Refrigerant Line Connections & Charging.............................................................. 16

3.7.1 Preparation......................................................................................................... 16

3.7.2 Conguring Air-Handler For A Single Or Dual Refrigerant Circuits.................... 16

3.7.3 Refrigerant Lines................................................................................................ 17

3.7.4 Liquid Line Filter Drier........................................................................................ 17

3.7.5 Brazing............................................................................................................... 18

3.7.6 Leak Testing....................................................................................................... 18

3.7.7 Evacuation.......................................................................................................... 18

3.7.8 Refrigerant Charging.......................................................................................... 18

3.8 TXV Sensing Bulb Attachment................................................................................ 18

3.9 Condensate Drain................................................................................................... 19

3.10 Thermostat............................................................................................................ 19

3.11 Electrical Wiring..................................................................................................... 20

3.11.1 Power Wiring..................................................................................................... 20

3.11.1.1 No-Heat Applications................................................................................... 20

3.11.1.2 Electric Heat Applications............................................................................ 20

3.11.2 Grounding......................................................................................................... 20

3.11.3 Electrical Data – Without Electric Heat............................................................ 21

3.11.4 Electrical Data – With Electric Heat................................................................. 21

3.11.5 Copper Wire Size ............................................................................................ 21

3.11.6 Electric Heater Kit Identication Label.............................................................. 22

3.11.7 Control Wiring................................................................................................... 22

3.11.7.1 No-Heat Applications................................................................................... 22

3.11.7.2 Electric Heat Applications............................................................................ 22

3.11.7.3 Conguring Outdoor Unit Transformer For 208V Applications.................... 22

3.11.8 Wiring Connection Diagrams............................................................................ 23

TABLE OF CONTENTS (continued)

3.12 Air-ow................................................................................................................. 24

3.12.1 Drive Package Data ...................................................................................... 25

3.12.2 Air-Flow Performance Data............................................................................ 26

3.12.3 Component Air-Resistance Data.................................................................... 27

3.12.4 Selecting The Proper Blower Drive & Motor Sheave Setting......................... 27

3.12.5 Field Supplied Blower Drives.......................................................................... 27

3.12.6 Adjusting The Variable Pitch Motor Sheave................................................... 27

3.12.7 Drive Belt Alignment & Adjustment................................................................. 28

4.0 Start-Up...................................................................................................................... 28

4.1 Pre-Start Checklist................................................................................................. 28

4.2 System Start-Up & Operational Check-Out........................................................... 28

4.3 Checking Indoor Air-Flow Rate............................................................................. 29

4.3.1 Estimating Air-Flow Rate Using External Static Pressure................................ 29

4.3.2 Estimating Air-Flow Rate Using Electric Heat Temperature Rise..................... 29

4.3.3 Correcting Electric Heat Kw For Voltage.......................................................... 29

4.3.4 Calculating Electric Heat Capacity In Btu........................................................ 29

4.4 Checking Refrigerant Charge................................................................................ 29

4.5 Sequence Of Operation......................................................................................... 30

4.5.1 Cooling & Heat Pump Heating Modes.............................................................. 30

4.5.2 Electric Heat Mode........................................................................................... 30

4.5.3 Supplemental Heating During The Heat Pump Heating & Defrost Modes....... 30

4.5.4 Emergency Heat (Heat Pump)......................................................................... 30

4.5.5 Thermostat Fan Setting.................................................................................... 30

5.0 Field Installed Accessories & Kits.......................................................................... 31

5.1 Electric Resistance Heater Kits............................................................................. 31

5.2 Mixing Box Kits..................................................................................................... 32

5.3 Discharge Plenum, Discharge Grille, & Inlet Grille Kits........................................ 34

5.4 Filter Frame Kits.................................................................................................... 35

5.5 Hot Water & Steam Coils....................................................................................... 36

6.0Maintenance............................................................................................................... 37

6.1 Air-Filters................................................................................................................ 37

6.2 Coil, Drain Pan, Drain Line................................................................................... 37

6.3 Blower Lubrication & Cleaning.............................................................................. 37

6.4 Blower Shaft Bearings, Bearing Collar Set Screws, Blower Wheel, Sheaves, &

Blower Drive Belt(S).............................................................................................. 37

6.5 Motor Replacement............................................................................................... 37

6.6 Replacement Parts................................................................................................ 37

7.0Diagnostics................................................................................................................ 38

8.0 Wiring Diagram.......................................................................................................... 39

CAUTION (SEE SECTION 3.3: AUXILIARY OVERFLOW PAN)

In compliance with recognized codes, an auxiliary drain pan must be installed

under all equipment containing evaporator coils that are located in any area of

a structure where damage to the building or building contents may occur as a

result of an overow of the coil drain pan or a stoppage in the primary conden-

sate drain piping.

WARNING (SEE SECTION 3.6: AIR FILTER)

Do not operate the system without lters. A portion of the dust entrained in

the air may temporarily lodge in the duct runs and at the supply registers. Any

circulated dust particles could be heated and charred by contact with the heat-

ing elements. This residue could soil ceilings, walls, drapes, carpets and other

articles in the building.

Soot damage may occur even with lters in place when certain types of can-

dles, oil lamps or standing pilots are burned.

WARNING

The rst 36 inches of supply air plenum and ductwork must be constructed

of sheet metal with no openings, registers or exible air ducts located in it as

required by NFPA 90B if an electric heater accessory is installed. If exible

supply air ducts are used they may be located only in the vertical walls of a

rectangular plenum, a minimum of 6 inches from the solid bottom.

WARNING

Because of possible damage

to equipment or personal injury,

installation, service, and mainte-

nance should be performed by a

trained, qualified service person-

nel. Never operate the unit with the

access panels removed.

WARNING

These instructions are intended as an aid to qualied, licensed service per-

sonnel for proper installation, adjustment and operation of this unit. Read

these instructions thoroughly before attempting installation or operation.

Failure to follow these instructions may result in improper installation, adjust-

ment, service or maintenance possibly resulting in re, electrical shock, prop-

erty damage, personal injury or death.

WARNING

If removal of the blower assembly

is required, all disconnect switches

supplying power to the equipment

must be de-energized and locked

(if not in sight of unit) so the eld

power wires can be safely removed

from the blower assembly. Failure

to do so can cause electrical shock

resulting in personal injury or death.

WARNING

Disconnect all power to unit before

installing or servicing. More than

one disconnect switch may be

required to de-energize the equip-

ment. Hazardous voltage can cause

severe personal injury or death.

WARNING

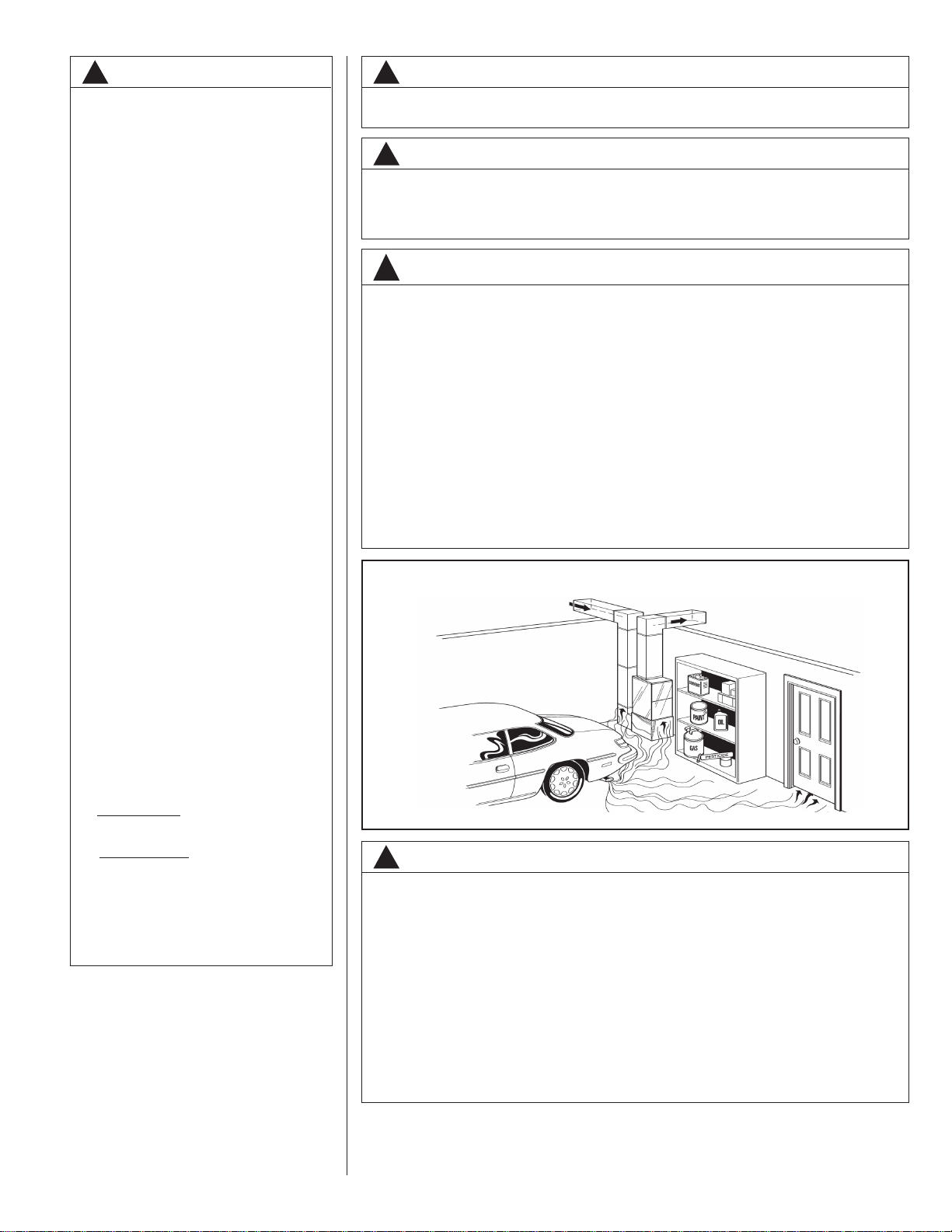

Duct leaks can create an unbalanced system and draw pollutants such as dirt,

dust, fumes and odors into the building causing property damage. Fumes

and odors from toxic, volatile or ammable chemicals, as well as automobile

exhaust and carbon monoxide (CO), can be drawn into the occupied space

through leaking ducts and unbalanced duct systems causing personal injury

or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage stor-

age areas - all joints, seams, and openings in the equipment and duct must

be sealed to limit the migration of toxic fumes and odors including carbon

monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers –all joints, seams, and

openings in the equipment and duct must also be sealed to prevent depres-

surization of the space and possible migration of combustion byproducts

including carbon monoxide into the occupied space.

WARNING (SEE SECTION 3.5: DUCTWORK)

Do not, under any circumstances, connect return ductwork to any other heat

producing device such as replace insert, stove, etc. Unauthorized use of

such devices may result in re, carbon monoxide poisoning, explosion, per-

sonal injury or property damage.

WARNING (SEE SECTION 3.11.3: GROUNDING)

The unit must be permanently grounded. Failure to do so can result in electri-

cal shock causing personal injury or death.

Carbon Monoxide (CO) Poisoning

Can Cause Severe Injury or Death.

Carbon Monoxide from the exhaust of motor

vehicles and other fuel burning devices can be

drawn into the living space by the operation of the

central heating and air conditioning system.

Exhaust from motor vehicles, generators, garden

tractors, mowers, portable heaters, charcoal and gas

grills, gasoline powered tools, and outdoor camping

equipment contains carbon monoxide, a poisonous gas

that can kill you. You cannot see it, smell it, or taste it.

•

Do NOT operate an automobile or any engine in a

garage for more than the few seconds it takes to

enter or exit the garage.

•

Do NOT operate any fuel-burning device in an

enclosed or partly enclosed space, or near

building windows, doors or air intakes.

The U.S. Consumer Product Safety Commission (CPSC)

and Health Canada recommend the installation of UL or

CSA certied Carbon Monoxide Alarm(s) in every home.

WARNING

!

!

!

1.0 SAFETY INFORMATION

!

!

!

!

!

!

!

WARNING

PROPOSITION 65: This appliance con-

tains fiberglass insulation. Respi-

rable particles of fiberglass are

known to the State of California to

cause cancer.

All manufacturer products meet

current Federal OSHA Guidelines for

safety. California Proposition 65

warnings are required for certain

products, which are not covered by

the OSHA standards.

California’s Proposition 65 requires

warnings for products sold in Cali-

fornia that contain or produce any

of over 600 listed chemicals known

to the State of California to cause

cancer or birth defects such as

berglass insulation, lead in brass,

and combustion products from nat-

ural gas.

All “new equipment” shipped for

sale in California will have labels

stating that the product contains

and/or produces Proposition 65

chemicals. Although we have not

changed our processes, having the

same label on all our products facil-

itates manufacturing and shipping.

We cannot always know “when, or

if” products will be sold in the Cali-

fornia market.

You may receive inquiries from

customers about chemicals found

in, or produced by, some of our

heating and air-conditioning equip-

ment, or found in natural gas used

with some of our products. Listed

below are those chemicals and sub-

stances commonly associated with

similar equipment in our industry

and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO)

• Formaldehyde

• Benzene

More details are available at the

websites for OSHA (Occupational

Safety and Health Administration),

at www.osha.gov and the State of Cal-

ifornia’s OEHHA (Ofce of Environ-

mental Health Hazard Assessment),

at www.oehha.org. Consumer educa-

tion is important since the chem-

icals and substances on the list

are found in our daily lives. Most

consumers are aware that products

present safety and health risks,

when improperly used, handled and

maintained.

NOTICE

When used in cooling applications, excessive sweating may occur when unit

is installed in an unconditioned space. This can result in property damage.

NOTICE

Improper installation, or installation not made in accordance with the Under-

writers Laboratory (UL) certication or these instructions, can result in unsat-

isfactory operation and/or dangerous conditions and are not covered by the

unit warranty.

NOTICE

Use of this air-handler during construction is not recommended. If operation

during construction is absolutely required, the following temporary installation

requirements must be followed:

Installation must comply with all Installation Instructions in this manual includ-

ing the following items:

• Properly sized power supply and circuit breaker/fuse

• Air-handler operating under thermostatic control;

• Return air duct sealed to the air-handler;

• Air lters must be in place;

• Correct air-ow setting for application

• Clean air-handler, duct work, and components including coil upon comple-

tion of the construction process and verify proper air-handler operating con-

ditions according as stated in this instruction manual.

• NOTE: Electric strip heater elements tend to emit a burning odor for a few

days if dust has accumulated during construction. Heater elements are easi-

ly damaged. Take great care when cleaning them. Low pressure compressed

air is recommended for cleaning elements.

WARNING

Duct leaks can create an unbalanced system and draw pollutants such as dirt,

dust, fumes and odors into the building causing property damage. Fumes

and odors from toxic, volatile or ammable chemicals, as well as automo-

bile exhaust and carbon monoxide (CO), can be drawn into the living space

through leaking ducts and unbalanced duct systems causing personal injury

or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage stor-

age areas –all joints, seams, and openings in the equipment and duct must

be sealed to limit the migration of toxic fumes and odors including carbon

monoxide from migrating into the occupied space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers –all joints, seams, and

openings in the equipment and duct must also be sealed to prevent depres-

surization of the space and possible migration of combustion byproducts

including carbon monoxide into the occupied space.

! !

!

!

!

FIGURE 1

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

Adapted from Residential Duct Diagnostics and Repair, with permission of Air Conditioning Contractors of America (ACCA).

2.0 GENERAL INFORMATION

2.1 IMPORTANT INFORMATION ABOUT EFFICIENCY & INDOOR

AIR QUALITY

&HQWUDOFRROLQJDQGKHDWLQJHTXLSPHQWLVRQO\DV敦晩捩敮琠DVWKHGXFWV\VWHPWKDWFDU

ULHVWKHFRROHGRUKHDWHGDLU7RPDLQWDLQ敦晩捩敮捹ⰠFRPIRUWDQGJRRGLQGRRUDLUTXDOLW\

LWLVLPSRUWDQWWRKDYHWKHSURSHUEDODQFHEHWZHHQWKHDLUEHLQJVXSSOLHGWRHDFKURRP

DQGWKHDLUUHWXUQLQJWRWKHFRROLQJDQGKHDWLQJHTXLSPHQW

3URSHUEDODQFHDQGVHDOLQJRIWKHGXFWV\VWHPLPSURYHVWKH敦晩捩敮捹RIWKHKHDWLQJ

DQGDLUFRQGLWLRQLQJV\VWHPDQGLPSURYHVWKHLQGRRUDLUTXDOLW\RIWKHKRPHE\UHGXFLQJ

WKHDPRXQWRIDLUERUQHSROOXWDQWVWKDWHQWHUKRPHVIURPVSDFHVZKHUHWKHGXFWZRUN

DQGRUHTXLSPHQWLVORFDWHG7KHPDQXIDFWXUHUDQGWKH86(QYLURQPHQWDO3URWHFWLRQ

$JHQF\¶V(QHUJ\6WDU3URJUDPUHFRPPHQGWKDWFHQWUDOGXFWV\VWHPVEHFKHFNHGE\D

煵慬楦楥搠捯湴牡捴潲潲⁰牯灥爠扡污湣攠慮搠獥慬楮朮

2.2 CHECKING PRODUCT RECEIVED

,PPHGLDWHO\XSRQUHFHLSWDOOFDUWRQVDQGFRQWHQWVVKRXOGEHLQVSHFWHGIRUWUDQVLWGDP

DJH8QLWVZLWKGDPDJHGFDUWRQVVKRXOGEHRSHQHGLPPHGLDWHO\,IGDPDJHLVIRXQGLW

VKRXOGEHQRWHGRQWKHGHOLYHU\GRFXPHQWVDQGDGDPDJHFODLP晩汥搠ZLWKWKHGHOLYHULQJ

FDUULHU

$IWHUXQLWKDVEHHQGHOLYHUHGWRWKHMREVLWHUHPRYHWKHXQLWIURPWKHSDFNDJLQJWDNLQJ

FDUHQRWWRGDPDJHWKHXQLW&KHFNWKHXQLWUDWLQJSODWHIRUXQLWPRGHOQXPEHUXQLWVL]H

癯汴慧攬⁰桡獥Ⱐ整挮⁴漠慳獵牥⁴桥⁵湩琠浡瑣桥猠瑨攠橯戠獰散楦楣慴楯湳

5HIHUHQFHWKHXQLWGDWDSODWHIRUWKHIROORZLQJLQIRUPDWLRQ

0RGHO1XPEHU &RXQWU\RI2ULJLQ

6HULDO1XPEHU 5DWHG9ROWDJHDQG)UHTXHQF\

120 RAC2

A

LCHR

'5,9(3$&.$*(

5 67$1'$5'

6 237,21$/

7 237,21$/

(/(&75,&$/'(6,*1$7,21

& 93++=

&22/,1*&$3$&,7<120,1$/

%78+5721

%78+57216

%78+5721

%78+5721

%78+5721

'(6,*16(5,(6

/ 5$5()5,*(5$17

75$'(%5$1'

+25,=217$/9(57,&$/',5(&7(;3$16,21

$,5+$1'/(5

$ $&

3 +3

9)'67$*(

'(6,*16(5,(6

2.3 MODEL NUMBER NOMENCLATURE

2.4 AVAILABLE MODELS

Available 230/230V/3-Phase/60 Hz Models

(-)HCLA2090CAR

(-)HCLA2090CAS

(-)HCLA2090CAT

(-)HCLP2090CAR

(-)HCLP2090CAS

(-)HCLP2090CAT

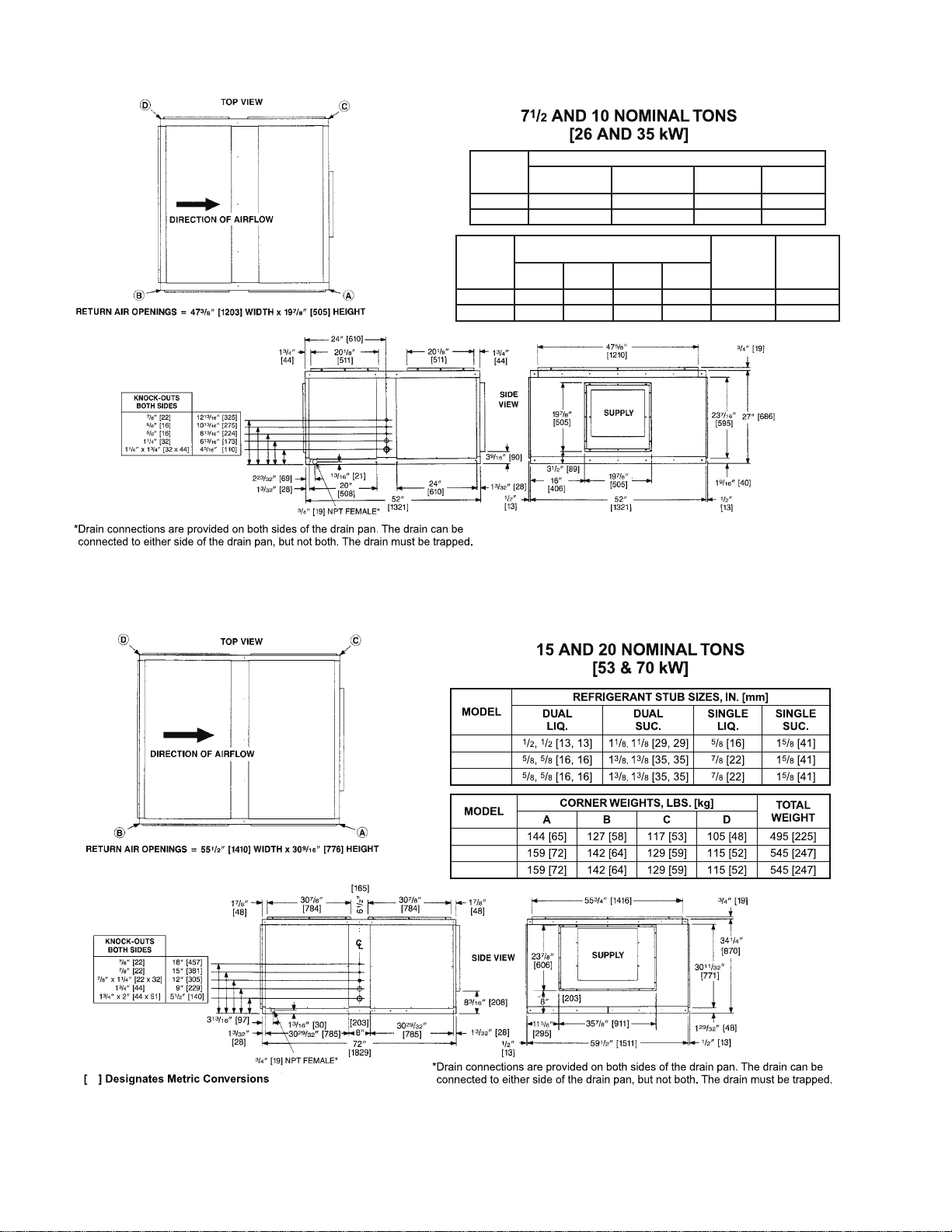

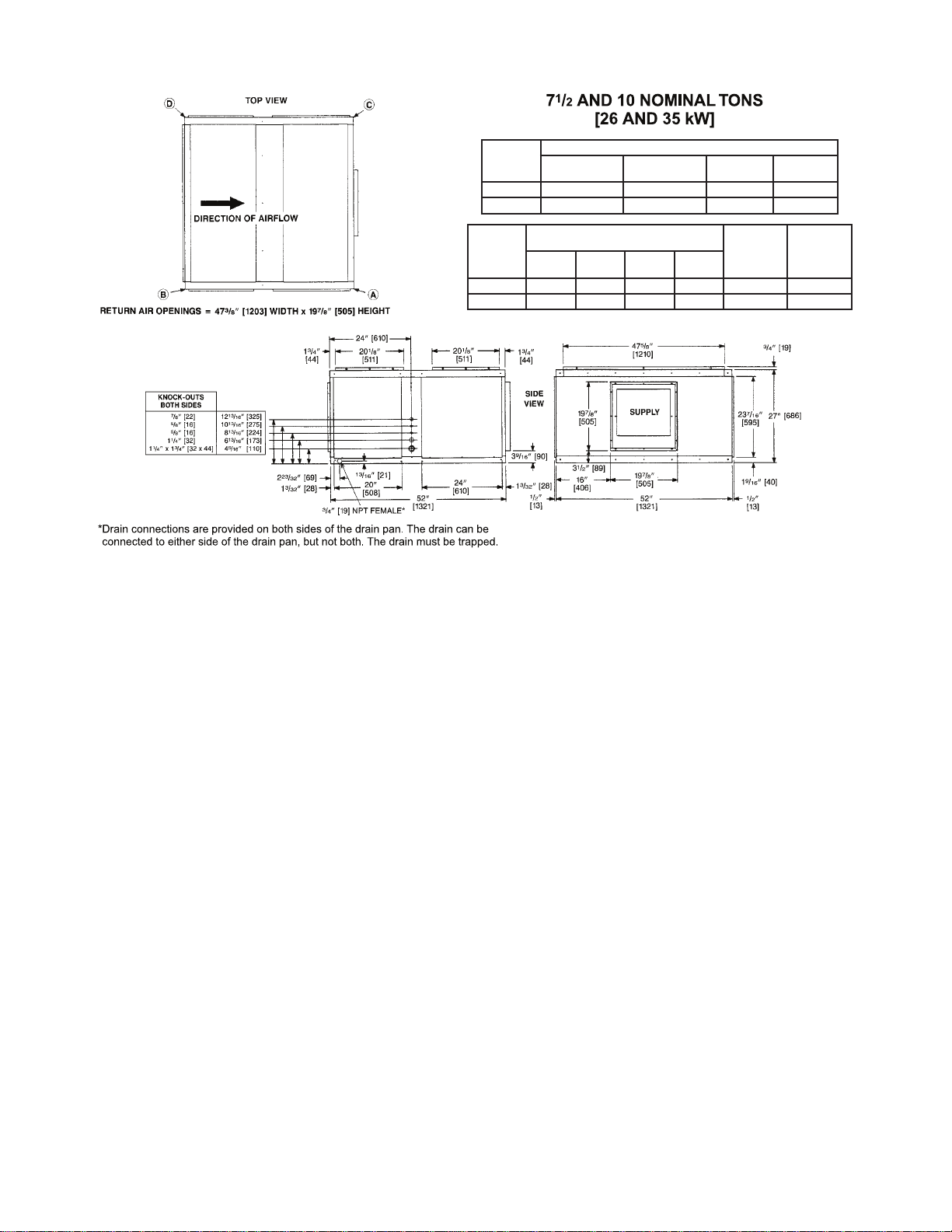

2.5 PHYSICAL DIMENSIONS – INCHES [mm]

+&/$

+&/$

5+&/3

+&/$

+&/$

5+&/3

MODEL

REFRIGERANT STUB SIZES, IN. [mm]

DUAL

LIQ.

DUAL

SUC.

SINGLE

LIQ.

SINGLE

SUC.

090 1/2, 1/2 [13, 13] 7/8, 7/8 [22, 22] 1/2 [13] 1 1/8 [29]

120 1/2, 1/2 [13, 13] 7/8, 7/8 [22, 22] 5/8 [16] 1 3/8 [35]

MODEL

REFRIGERANT STUB SIZES, IN.

[mm] TOTAL

WEIGHT

GROSS

WEIGHT

ABCD

090 127 [57] 57 [25] 50 [22] 131 [59] 365 [165] 409 [185]

120 127 [57] 57 [25] 50 [22] 131 [59] 365 [165] 409 [185]

+&/$

+&/$

5+&/3

MODEL

REFRIGERANT STUB SIZES, IN. [mm]

DUAL

LIQ.

DUAL

SUC.

SINGLE

LIQ.

SINGLE

SUC.

090 1/2, 1/2 [13, 13] 7/8, 7/8 [22, 22] 1/2 [13] 1 1/8 [29]

120 1/2, 1/2 [13, 13] 7/8, 7/8 [22, 22] 5/8 [16] 1 3/8 [35]

MODEL

REFRIGERANT STUB SIZES, IN.

[mm] TOTAL

WEIGHT

GROSS

WEIGHT

ABCD

090 127 [57] 57 [25] 50 [22] 131 [59] 365 [165] 409 [185]

120 70 [31] 145 [65] 123 [55] 66 [29] 403 [182] 447 [202]

2.6 PHYSICAL DATA

(-)HCLA2 (-)HCLA2 (-)HCLP2 (-)HCLP2

Cooling Size 090 120 090 120

Nominal size (tons) 7-1/2 10 7-1/2 10

Nominal CFM @ Rated E.S.P. (2nd

Stage) 3000 @ .25” 4000 @ .30” 3000 @ .35” 4000 @ .35”

# of Blower Speeds 2222

1 st Stage Blower RPM % 63% 63% 63% 63%

MOTOR HORSE-

POWER

Standard-

1750 RPM 3 phase 2 HP 2 HP 2 HP 2 HP

Optional-

1750 RPM 3 phase 2 HP, 3 HP 2 HP, 3 HP 2 HP, 3 HP 2 HP, 3 HP

Blower Size - diameter x width 12 X 12 12 X 12 12 X 12 12 X 12

Blower Shaft Diameter 3/4 3/4 3/4 3/4

Motor Sheave 1750 RPM 3 phase 1VP50 4.4 - 5.0 1VP50 AVL40

Belt Type & Size Std. A-50 V-54 A-50 A-52

Coil Face Area (sq. ft.) 10.2 10.2 10.2 10.2

Coil Tube Diameter 3/8 3/8 3/8 3/8

Coil, Rows Deep-Fins Per Inch 4/15 4/15 4/15 4/15

T.X. Valve Refrigerant Control (2) CBBIZE-5-GA (2) CBBIZE-5-GA (2) CBBIZE-5-GA (2) CBBIZE-6-GA

Filter Size (std.)* No. Req’d (4) 16 X 25 X 1 (4) 16 X 25 X 1 (4) 16 X 25 X 1 (4) 16 X 25 X 1

CABINET:

Finish Prepaint Prepaint Prepaint Prepaint

Sheet Metal Galvanized Galvanized Galvanized Galvanized

Gauge: Top 18 18 18 18

Sides 16 16 16 16

Bottom 18 18 18 18

Door and Covers 20 min. 20 min. 20 min. 20 min.

UNIT WEIGHTS:

Operating 330 (R & S Drive)

341 (T Drive)

347 (R & S Drive)

358 (T Drive)

330 (R & S Drive)

341 (T Drive)

447 (R & S Drive)

458 (T Drive)

Shipping 396 (R & S Drive)

407 (T Drive)

413 (R & S Drive)

435 (T Drive)

365 (R & S Drive)

376 (T Drive)

513 (R & S Drive)

535 (T Drive)

OPTIONAL ACCESORIES WEIGHTS:

Hot Water Coils 200 200 200 200

Steam Heating Coils 200 200 200 200

Unit shown with side panel removed for coil connections and air lter access.

Low Voltage

Terminal Block (TB2)

Control Box

Line Voltage

Terminal Block (TB1)

Variable Frequency Drive (VFD)

Note: Remove panel with

unit data plate to access

this compartment

2.7 MAJOR COMPONENTS

EVAPORATOR

COIL FILTERS

CABINET

MOTOR

EITHER

SIDE

REFRIGERANT

CONNECTION

LOCATION

2.8 IMPORTANCE OF PROPER INDOOR/OUTDOOR MATCH-UPS

7RDVVXUHPDQ\\HDUVRIUHOLDEOHRSHUDWLRQDQGRSWLPXPFXVWRPHUFRPIRUWDQGWRDVVXUH

WKHRXWGRRUXQLWZDUUDQW\UHPDLQVYDOLGDQDLUKDQGOHUPRGHOVKRXOGEHVHOHFWHGWKDWLV

SURSHUO\PDWFKHGWRWKHRXWGRRUXQLW7KLVLVHVSHFLDOO\FULWLFDOIRUKHDWSXPSV\VWHPVWR

DVVXUHSURSHUUHIULJHUDQWFKDUJHEDODQFHEHWZHHQWKHFRROLQJDQGKHDWLQJPRGHV7KH

UHFRPPHQGHGDSSURDFKLVWRVHOHFWDQDLUKDQGOHUPRGHOWKDWKDVDQ$+5,PDWFKZLWK

WKHRXWGRRUXQLW5HIHUWRWKH$+5,GLUHFWRU\DWwww.ahridirectory.orgWR捯湦楲洠WKH

慩爭桡湤汥爠慮搠潵瑤潯爠畮楴牥敲瑩晩敤潭扩湡瑩潮渠瑨攠$+5,'LUHFWRU\

2.9 IMPORTANCE OF A QUALITY INSTALLATION

$TXDOLW\LQVWDOODWLRQLVFULWLFDOWRDVVXUHVDIHW\UHOLDELOLW\FRPIRUWDQGFXVWRPHUVDWLV

IDFWLRQ6WULFWDGKHUHQFHWRDSSOLFDEOHFRGHVWKHLQIRUPDWLRQLQWKLVLQVWDOODWLRQPDQXDO

WKHRXWGRRUXQLWLQVWDOODWLRQPDQXDODQGWKHWKHUPRVWDWLQVWDOODWLRQPDQXDODUHNH\WRD

TXDOLW\LQVWDOODWLRQ5HDGWKHHQWLUHLQVWUXFWLRQPDQXDOVEHIRUHVWDUWLQJWKHLQVWDOODWLRQ

IMPORTANT: 7KLVSURGXFWKDVEHHQGHVLJQHGDQGPDQXIDFWXUHGWRPHHW捥牴楦楥

$+5,FDSDFLW\DQG敦晩捩敮捹UDWLQJVZLWKWKHDSSURSULDWHRXWGRRUXQLWV+RZHYHUSURS

HUUHIULJHUDQWFKDUJHSURSHU慩牦汯眬DQGUHIULJHUDQWOLQHVL]LQJDUHFULWLFDOWRDFKLHYH

RSWLPXPFDSDFLW\DQG敦晩捩敮捹DQGWRDVVXUHUHOLDEOHRSHUDWLRQ,QVWDOODWLRQRIWKLV

SURGXFWVKRXOGIROORZWKHPDQXIDFWXUHU¶VUHIULJHUDQWFKDUJLQJDQG慩牦汯眠LQVWUXFWLRQV

ORFDWHGLQWKHRXWGRRUXQLWLQVWDOODWLRQLQVWUXFWLRQVDQGWKHFKDUJLQJFKDUWODEHO慦晩硥搠WR

WKHRXWGRRUXQLW)DLOXUHWR捯湦楲洠SURSHUFKDUJHDQG慩牦汯眠PD\UHGXFHHQHUJ\敦晩

FLHQF\DQGVKRUWHQHTXLSPHQWOLIH

7KHHTXLSPHQWKDVEHHQHYDOXDWHGLQDFFRUGDQFHZLWKWKH&RGHRI)HGHUDO5HJXOD

WLRQV&KDSWHU;;3DUW

,QVWDOOWKHXQLWLQDFFRUGDQFHZLWKDSSOLFDEOHQDWLRQDOVWDWHDQGORFDOFRGHV/DWHVWHGL

WLRQVDUHDYDLODEOHIURP³1DWLRQDO)LUH3URWHFWLRQ$VVRFLDWLRQ,QF%DWWHU\PDUFK3DUN

4XLQF\0$´7KHVHSXEOLFDWLRQVDUH

$16,1)3$1R/DWHVW(GLWLRQ1DWLRQDO(OHFWULFDO&RGH

1)3$$,QVWDOODWLRQRI$LU&RQGLWLRQLQJDQG9HQWLODWLQJ6\VWHPV

1)3$%,QVWDOODWLRQRI:DUP$LU+HDWLQJDQG$LU&RQGLWLRQLQJ6\VWHPV

,QVWDOOWKHXQLWLQVXFKDZD\DVWRDOORZQHFHVVDU\DFFHVVWRWKHFRLO晩汴HUUDFNDQG

EORZHUFRQWUROFRPSDUWPHQW

3.0 INSTALLATION

3.1 TOOLS & REFRIGERANT

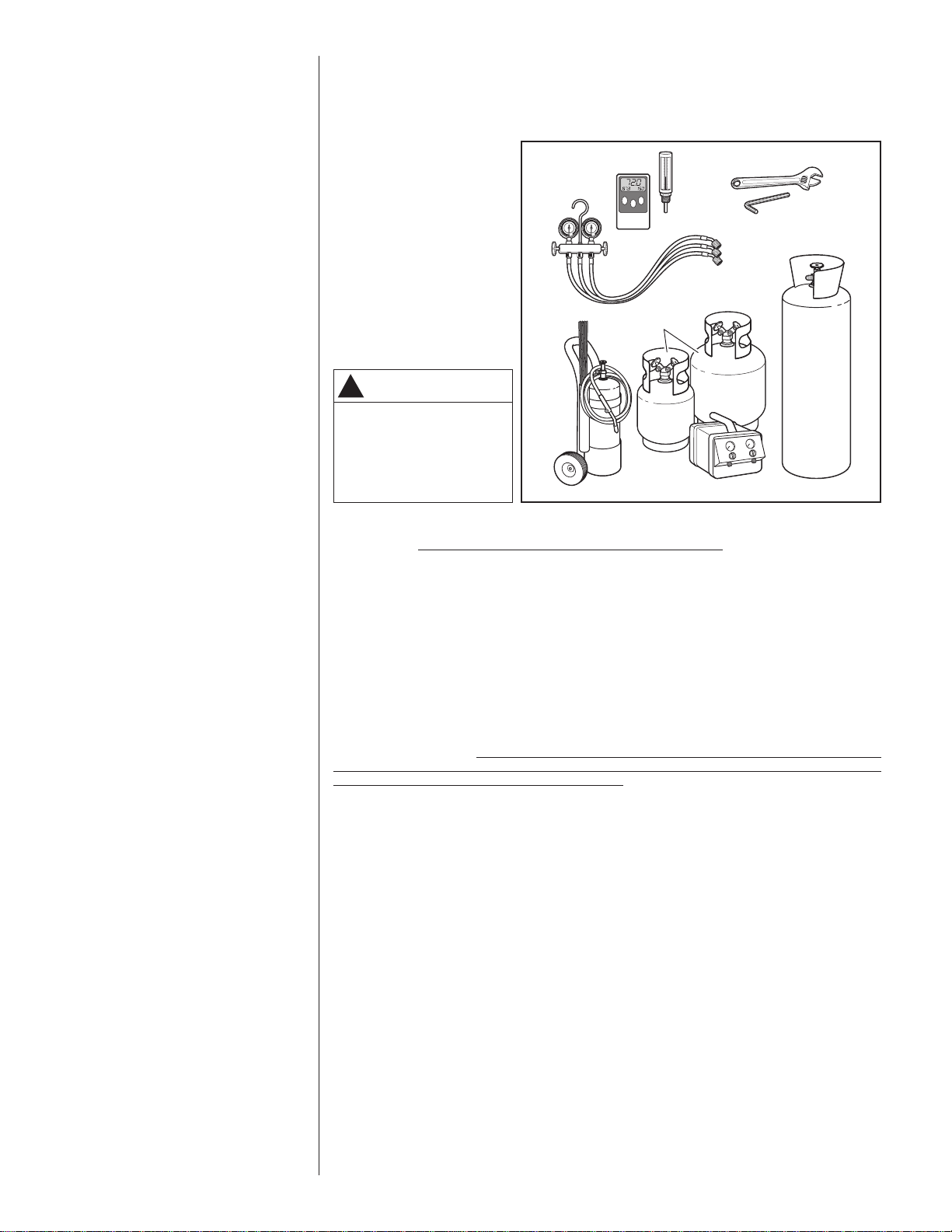

3.1.1 TOOLS REQUIRED FOR INSTALLING AND SERVICING R-410A MODELS

Manifold Sets:

8SWR36,*+LJK6LGH

8SWR36,*/RZ6LGH

36,*/RZ6LGH5HWDUG

Manifold Hoses:

6HUYLFH3UHVVXUH5DWLQJRI

36,*

Recovery Cylinders:

36,*3UHVVXUH5DWLQJ

'HSWRI7UDQVSRUWDWLRQ

%$RU%:

3.1.2 SPECIFICATIONS OF R-410A

Application:R-410A is not a drop-in replacement for R-22.(TXLSPHQWGHVLJQVPXVW

慣捯浭潤慴攠楴猠桩杨敲⁰牥獳畲敳⸠䥴慮湯琠扥整牯晩瑴敤湴漠刭㈲敡琠灵浰献

Physical Properties:5$KDVDQDWPRVSKHULFERLOLQJSRLQWRI)>&@DQG

LWVVDWXUDWLRQSUHVVXUHDW)>&@LVSVLJ

Composition:5$LVDQHDUD]HRWURSLFPL[WXUHRIE\ZHLJKW摩晬畯牯浥瑨慮攠

⡈䙃ⴳ㈩湤‵〥礠睥楧桴⁰敮瑡晬畯牯整桡湥䡆䌭ㄲ㔩

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than

R-22. 5HFRYHU\DQGUHF\FOHHTXLSPHQWSXPSVKRVHVDQGWKHOLNHPXVWKDYHGHVLJQ

SUHVVXUHUDWLQJVDSSURSULDWHIRU5$0DQLIROGVHWVQHHGWRUDQJHXSWRSVLJ

KLJKVLGHDQGSVLJORZVLGHZLWKDSVLJORZVLGHUHWDUG+RVHVQHHGWRKDYHD

VHUYLFHSUHVVXUHUDWLQJRISVLJ5HFRYHU\F\OLQGHUVQHHGWRKDYHDSVLJVHUYLFH

SUHVVXUHUDWLQJ'27%$RU'27%:

Combustibility:$WSUHVVXUHVDERYHDWPRVSKHUHDPL[WXUHRI5$DQGDLUFDQ

EHFRPHFRPEXVWLEOHR-410A and air should never be mixed in tanks or supply

lines or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air./HDNFKHFNLQJFDQEHSHUIRUPHGVDIHO\

ZLWKQLWURJHQRUDPL[WXUHRI5$DQGQLWURJHQ

3.1.3 QUICK-REFERENCE GUIDE FOR R-410A

5$UHIULJHUDQWRSHUDWHVDWDSSUR[LPDWHO\KLJKHUSUHVVXUHWLPHVWKDQ

5(QVXUHWKDWVHUYLFLQJHTXLSPHQWLVGHVLJQHGWRRSHUDWHZLWK5$

5$UHIULJHUDQWF\OLQGHUVDUHOLJKWURVHLQFRORU

5$DVZLWKRWKHU+)&VLVRQO\FRPSDWLEOHZLWK32(RLOV

9DFXXPSXPSVZLOOQRWUHPRYHPRLVWXUHIURP32(RLOXVHGLQ5$V\VWHPV

5$V\VWHPVDUHWREHFKDUJHGZLWKOLTXLGUHIULJHUDQWV3ULRUWR0DUFK

5$UHIULJHUDQWF\OLQGHUVKDGDGLSWXEH7KHVHF\OLQGHUVVKRXOGEHNHSWXSULJKW

IRUHTXLSPHQWFKDUJLQJ3RVW0DUFKF\OLQGHUVGRQRWKDYHDGLSWXEHDQGVKRXOG

EHLQYHUWHGWRHQVXUHOLTXLGFKDUJLQJRIWKHHTXLSPHQW

䑯潴湳瑡汬畣瑩潮楮攠晩汴敲物敲渠瑨攠汩煵楤楮攮

$IDFWRU\DSSURYHGRXWGRRUOLTXLGOLQH晩汴敲GULHULVVKLSSHGZLWKHYHU\XQLWDQGPXVW

EHLQVWDOOHGLQWKHOLTXLGOLQHDWWKHWLPHRILQVWDOODWLRQ,IRQO\WKHDLUKDQGOHULVEHLQJ

UHSODFHGRQDQH[LVWLQJV\VWHPWKHH[LVWLQJ晩汴敲GULHUPXVWEHUHSODFHGDWWKHWLPH

RILQVWDOODWLRQZLWKD晩敬搠VXSSOLHG晩汴敲GULHU IMPORTANT:$扩ⵦ汯眠晩汴敲GULHUPXVW

EHXVHGIRUKHDWSXPSDSSOLFDWLRQV)LOWHUGULHUVPXVWEHUDWHGIRUPLQLPXPZRUNLQJ

SUHVVXUHRISVLJ7KH晩汴敲GULHUZLOORQO\KDYHDGHTXDWHPRLVWXUHKROGLQJFDSDFL

W\LIWKHV\VWHPLVSURSHUO\HYDFXDWHG

'HVLFFDQWGU\LQJDJHQWPXVWEHFRPSDWLEOHIRU32(RLOVDQG5$UHIULJHUDQW

Ambient and Tube

Thermometers

Manifold

Gauge

Set

Brazing

Rods

Torch Nitrogen

Reclaimer

Recovery

Cylinders

Allen Wrench

Crescent Wrench

NOTICE

R-410A systems operate

at higher pressures than

R-22 systems. Do not

use R-22 service equip-

ment or components on

R-410A equipment.

!

3.2 APPLICATIONS & ORIENTATION

IMPORTANT:7KHDLUKDQGOHULVVXLWDEOHIRULQGRRUDSSOLFDWLRQVRQO\

3.2.1 HORIZONTAL DISCHARGE

7KHDLUKDQGOHUPD\EHLQVWDOOHGLQWKHKRUL]RQWDOGLVFKDUJH捯湦楧畲慴楯渠ZLWKHLWKHUD

YHUWLFDORUKRUL]RQWDOUHWXUQGXFWDVVKRZQLQ)LJXUH)RUDYHUWLFDOUHWXUQGXFWUHOR

FDWHWKHUHWXUQDLUSDQHORQWRSRIWKHDLUKDQGOHUWRFRYHUWKHVLGHUHWXUQDLURSHQLQJ

3.2.2 VERTICAL UP DISCHARGE

7KHDLUKDQGOHUPD\EHLQVWDOOHGLQWKHYHUWLFDOGLVFKDUJH捯湦楧畲慴楯渠ZLWKDKRUL]RQWDO

UHWXUQGXFWDVVKRZQLQ)LJXUH5HORFDWHWKHUHWXUQDLUSDQHOWRFRYHUWKHRWKHUUHWXUQ

DLURSHQLQJWRDOORZIRUWKHKRUL]RQWDOUHWXUQGXFW

SUPPLY AIR

VERTICAL

RETURN AIR

OPTION #1

HORIZONTAL

RETURN AIR

HORIZONTAL DISCHARGE

ST-A1293-02

VERTICAL

RETURN AIR

OPTION #2

FIGURE 2

HORIZONTAL DISCHARGE

ST-A1293-02

VERTICAL

RETURN AIR

SUPPLY AIR

HORIZONTAL

RETURN AIR

VERTICAL UP DISCHARGE

ST-A1293-01

FIGURE 3

VERTICAL UP DISCHARGE

ST-A1293-01

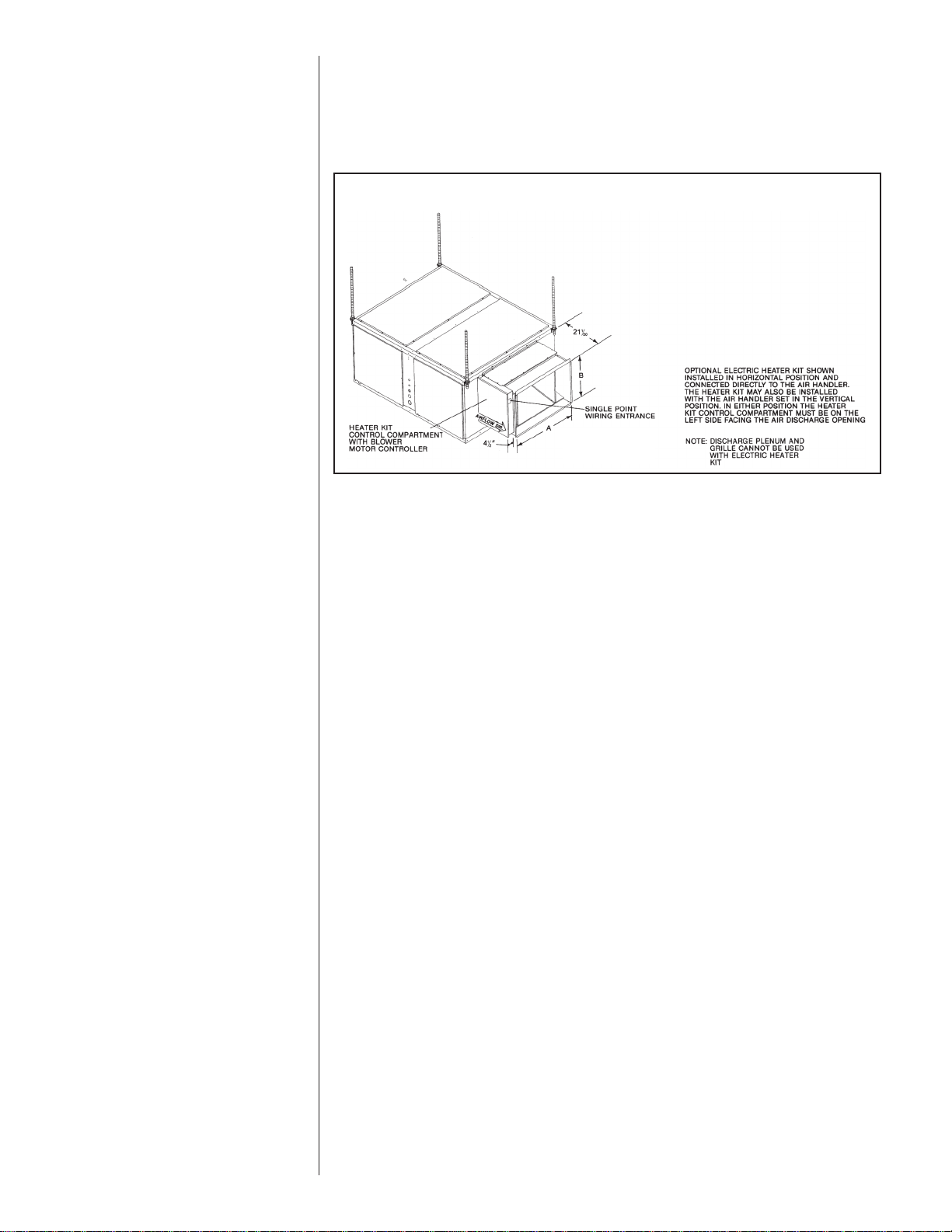

3.2.3 APPLICATIONS REQUIRING ELECTRIC HEAT

)RUDSSOLFDWLRQVWKDWUHTXLUHUHVLVWDQFHHOHFWULFKHDW晩敬搠LQVWDOOHGKHDWHUNLWVDUHDYDLO

DEOHWKDWDWWDFKHVWRWKHGLVFKDUJHVLGHRIWKHDLUKDQGOHU6HH)LJXUH7KHKHDWHUNLW

LVFRPSDWLEOHIRUERWKKRUL]RQWDODQGYHUWLFDOGLVFKDUJHDSSOLFDWLRQV7KHVXSSO\GXFW

PXVWEHDWWDFKHGWRWKHGLVFKDUJHHQGRIWKHKHDWHUNLW7KHEORZHUPRWRUFRQWDFWRUDQG

VXSSO\ZLULQJLVSURYLGHGZLWKWKHKHDWHUNLW6HH6HFWLRQIRULQIRUPDWLRQFRQFHUQLQJ

WKHDYDLODEOHKHDWHUNLWV

3.2.4 SUSPENDING UNIT

)RXUKHDY\JDXJHDQJOHVDUHIXUQLVKHGLQWKHSDUWVEDJVKLSSHGZLWKWKHDLUKDQGOHUIRU

VXVSHQGLQJWKHXQLWIURPDOOIRXUFRUQHUVDVVKRZQLQ)LJXUHDERYHò´PLQLPXPVXS

SRUWURGVDUHUHFRPPHQGHG,I³$OO7KUHDG´URGVDUHXVHGLWLVUHFRPPHQGHGWKDWWZR

QXWVDQGWZRORFNZDVKHUVEHWLJKWHQHGVHFXUHO\DJDLQVWWKHVXVSHQVLRQDQJOHV

:KHQWKHDLUKDQGOHULVVXVSHQGHGDVLOOXVWUDWHGKRWZDWHURUVWHDPFRLOVPL[LQJ

ER[HVDQGGLVFKDUJHDLUSOHQXPVFDQQRWEHPRXQWHGGXHWRZHLJKWOLPLWDWLRQV,QWKHVH

DSSOLFDWLRQVDQDOWHUQDWHVXVSHQVLRQPHWKRGVXFKDV晩敬搠VXSSOLHGDQJOHVRUFKDQQHOV

PXVWEHORFDWHGXQGHUQHDWKWKHDLUKDQGOHU

3.2.5 INSTALLATION IN AN UNCONDITIONED SPACE

7KHH[WHULRUFDELQHWRIDQDLUKDQGOHUKDVDJUHDWHUULVNRIVZHDWLQJZKHQLQVWDOOHGLQDQ

XQFRQGLWLRQHGVSDFHWKDQZKHQLWLVLQVWDOOHGLQWKHFRQGLWLRQHGVSDFH7KLVLVSULPDULO\

GXHWRWKHWHPSHUDWXUHRIWKHFRQGLWLRQHGDLUPRYLQJWKURXJKWKHDLUKDQGOHUDQGWKH

DLUFLUFXODWLQJDURXQGWKHXQLWZKHUHLWLVLQVWDOOHG)RUWKLVUHDVRQWKHIROORZLQJLVUHF

RPPHQGHGIRUDOODLUKDQGOHUDSSOLFDWLRQVEXWVSHFLDODWWHQWLRQVKRXOGEHSDLGWRWKRVH

LQVWDOOHGLQXQFRQGLWLRQHGVSDFHV

䑵捴楺楮朠慮搠慩牦汯眠慲攠捲楴楣慬湤畳琠扥慳敤渠瑨攠敱畩灭敮琠獥汥捴敤⸠

6XSSO\DQGUHWXUQGXFWDWWDFKPHQW,IRWKHUWKDQWKHIDFWRU\晬慮来猠DUHXVHGWKH

DWWDFKPHQWRIGXFWLQJPXVWEHLQVXODWHGDQGWLJKWWRSUHYHQWVZHDWLQJ

$SSO\FDXONLQJDURXQGDOOFDELQHWSHQHWUDWLRQVVXFKDVSRZHUZLUHVFRQWUROZLUHV

UHIULJHUDQWWXELQJDQGFRQGHQVDWHOLQHZKHUHWKH\HQWHUWKHFDELQHW6HDOWKHSRZHU

ZLUHVRQWKHLQVLGHZKHUHWKH\H[LWFRQGXLWRSHQLQJ6HDOLQJLVUHTXLUHGWRSUHYHQWDLU

OHDNDJHLQWRWKHXQLWZKLFKFDQUHVXOWLQFRQGHQVDWHIRUPLQJLQVLGHWKHXQLWFRQWURO

ER[DQGRQHOHFWULFDOFRQWUROV7DNHFDUHQRWWRGDPDJHUHPRYHRUFRPSUHVVLQVXOD

WLRQZKHQDSSO\LQJWKHFDXON

,QVRPHFDVHVWKHHQWLUHDLUKDQGOHUFDQEHZUDSSHGZLWKLQVXODWLRQ7KLVFDQEH

GRQHDVORQJDVWKHXQLWLVFRPSOHWHO\HQFORVHGLQLQVXODWLRQVHDOHGDQGVHUYLFH

DFFHVVLVSURYLGHGWRSUHYHQWDFFXPXODWLRQRIPRLVWXUHLQVLGHWKHLQVXODWLRQZUDS

$QDX[LOLDU\RYH牦汯ZSDQLVUHFRPPHQGHGWRSURWHFWWKHVWUXFWXUHIURPH[FHVVLYH

FDELQHWVZHDWLQJRUDUHVWULFWHGFRLOGUDLQOLQH6HH6HFWLRQ

3.2.6 INSTALLATION IN CORROSIVE ENVIRONMENTS

7KHPHWDOSDUWVRIWKLVXQLWPD\EHVXEMHFWWRUXVWRUGHWHULRUDWLRQLIH[SRVHGWRDFRU

URVLYHHQYLURQPHQWZKLFKFDQVKRUWHQLWVOLIH,QDGGLWLRQWRH[SRVXUHWRWKHH[WHULRURI

WKHFDELQHWFKHPLFDOFRQWDPLQDQWVLQVLGHWKHEXLOGLQJWKDWFDQEHGUDZQLQWRWKHXQLW

IURPWKHUHWXUQDLUJULOOHDQGDWWDFNVWUXFWXUDOPHWDOSDUWVHOHFWULFDOFRPSRQHQWVDQGWKH

LQGRRUFRLOFDXVLQJSUHPDWXUHIDLOXUHRIWKHXQLW,IWKHXQLWLVWREHLQVWDOOHGLQDQDUHD

ZKHUHFRQWDPLQDQWVDUHOLNHO\WREHDSUREOHPVSHFLDODWWHQWLRQVKRXOGEHJLYHQWRLVR

ODWHWKHXQLWDQGUHWXUQJULOOHIURPFRQWDPLQDQWV

FIGURE 4

APPLICATIONS REQUIRING ELECTRIC HEAT

3.3 AUXILIARY OVERFLOW PAN

,QFRPSOLDQFHZLWKUHFRJQL]HGFRGHVDQDX[LOLDU\潶敲晬潷SDQPXVWLQVWDOOHGXQGHUDOO

HTXLSPHQWFRQWDLQLQJHYDSRUDWRUFRLOVWKDWDUHORFDWHGLQDQ\DUHDRIDVWUXFWXUHZKHUH

GDPDJHWRWKHEXLOGLQJRUEXLOGLQJFRQWHQWVPD\RFFXUDVDUHVXOWRIDQ潶敲晬潷RIWKH

FRLOGUDLQSDQRUDVWRSSDJHLQWKHSULPDU\FRQGHQVDWHGUDLQSLSLQJ

3.4 CLEARANCES

$PLQLPXPRI´LVUHTXLUHGRQERWKVLGHVRIWKHDLUKDQGOHUIRUVHUYLFLQJWKHXQLW

3.5 DUCTWORK

)LHOGGXFWZRUNPXVWFRPSO\ZLWKWKH1DWLRQDO)LUH3URWHFWLRQ$VVRFLDWLRQ1)3$$

1)3$%DQGDQ\DSSOLFDEOHORFDORUGLQDQFH

6KHHWPHWDOGXFWZRUNUXQLQXQFRQGLWLRQHGVSDFHVPXVWEHLQVXODWHGDQGFRYHUHGZLWKD

YDSRUEDUULHU)LEURXVGXFWZRUNPD\EHXVHGLIFRQVWUXFWHGDQGLQVWDOOHGLQDFFRUGDQFH

ZLWK60$&1$&RQVWUXFWLRQ6WDQGDUGRQ)LEURXV*ODVV'XFWV'XFWZRUNPXVWFRPSO\

ZLWK1DWLRQDO)LUH3URWHFWLRQ$VVRFLDWLRQDVWHVWHGE\8/6WDQGDUGIRU&ODVV,$LU

'XFWV&KHFNORFDOFRGHVIRUUHTXLUHPHQWVRQGXFWZRUNDQGLQVXODWLRQ

'XFWV\VWHPPXVWEHGHVLJQHGZLWKLQWKHUDQJHRIH[WHUQDOVWDWLFSUHVVXUHWKHXQLWLV

GHVLJQHGWRRSHUDWHDJDLQVW,WLVLPSRUWDQWWKDWWKHV\VWHP慩牦汯眠EHDGHTXDWH0DNH

VXUHVXSSO\DQGUHWXUQGXFWZRUNJULOOV晩汴敲猬DFFHVVRULHVHWFDUHDFFRXQWHGIRULQ

WRWDOUHVLVWDQFH5HIHUWRWKH慩牦汯眠SHUIRUPDQFHWDEOHVLQWKLVPDQXDOWRGHWHUPLQHWKH

DYDLODEOHH[WHUQDOVWDWLFSUHVVXUHIRUWKHSDUWLFXODUDLUKDQGOHUPRGHOEHLQJLQVWDOOHG

'HVLJQWKHGXFWV\VWHPLQDFFRUGDQFHZLWK³$&&$´0DQXDO³4´±/RZ3UHVVXUH/RZ

9HORFLW\'XFW6\VWHP'HVLJQ/DWHVWHGLWLRQVDUHDYDLODEOHIURP³$&&$´$LU&RQ

GLWLRQLQJ&RQWUDFWRUVRI$PHULFDWK6WUHHW1::DVKLQJWRQ'&

,IGXFWV\VWHPLQFRUSRUDWHVexible air duct, EHVXUHpressure dropLQIRUPDWLRQ

VWUDLJKWOHQJWKSOXVDOOWXUQVVKRZQLQ³$&&$´0DQXDO³'´LVDFFRXQWHGIRULQV\VWHP

6XSSO\SOHQXP猠慴瑡捨敤⁴漠瑨攠摵捴污湧敳異灬楥搠睩瑨⁴HXQLW

IMPORTANT: ,IDQHOERZLVLQFOXGHGLQWKHSOHQXPFORVHWRWKHXQLWLWPXVWQRWEH

獭慬汥爠瑨慮⁴桥業敮獩潮猠潦⁴桥異灬礠摵捴污湧攠潮⁴桥⁵湩琮

IMPORTANT: 7KHIURQW晬慮来RQWKHUHWXUQGXFWLIFRQQHFWHGWRWKHEORZHUFDVLQJ

PXVWQRWEHVFUHZHGLQWRWKHDUHDZKHUHWKHSRZHUZLULQJLVORFDWHG'ULOOVRUVKDUS

VFUHZSRLQWVFDQGDPDJHLQVXODWLRQRQZLUHVORFDWHGLQVLGHXQLW

6HFXUHWKHVXSSO\DQGUHWXUQGXFWZRUNWRWKHXQLW晬慮来猬XVLQJSURSHUIDVWHQHUVIRU

WKHW\SHRIGXFWXVHGDQGWDSHRUFDXONWKHGXFWWRXQLWMRLQWDVUHTXLUHGWRSUHYHQWDLU

OHDNV

3.6 RETURN AIR FILTERS

$QLQWHUQDO晩汴敲UDFNLVSURYLGHGWKDWFDQEHDFFHVVHGE\UHPRYLQJRQHRUERWKRIWKH

VLGHVHUYLFHDFFHVVSDQHOV6HH6HFWLRQ5HPRYHWKHKLWFKSLQVWRUHPRYHWKH晩

WHUUHWDLQHUDQJOHV´WKLFNWKURZDZD\晩扥牧污獳晩汴敲猠DUHSURYLGHGIURPWKHIDFWRU\

扵琠瑨攠晩汴敲慣欠捡渠慣捥灴⁵瀠瑯′鐠瑨楣欠晩汴敲献

5HGXFHG慩爭晬潷FDQUHGXFHV\VWHPSHUIRUPDQFHDQGVKRUWHQWKHOLIHRIWKHV\VWHP

FRPSRQHQWVVXFKDVWKHFRPSUHVVRULQGRRUFRLOKHDWHUHOHPHQWVRYHUWHPSHUDWXUH

OLPLWVDQGUHOD\V7KHUHIRUHLWLVLPSRUWDQWWRFKDQJHWKH晩汴敲猠RQDUHJXODUEDVLVWR

DVVXUHRSWLPXPSHUIRUPDQFHDQGUHOLDELOLW\RIWKHV\VWHP

IMPORTANT:+LJK敦晩捩敮捹SOHDWHG晩汴敲猠W\SLFDOO\KDYH獩杮楦楣慮瑬礠KLJKHUSUHVVXUH

GURSWKDQVWDQGDUG敦晩捩敮捹晩扥牧污獳晩汴敲猬HVSHFLDOO\ZKHQWKH\EHFRPHGLUW\7KH

DGGLWLRQDOSUHVVXUHGURSRIVXFK晩汴敲猠PXVWEHDGGHGLQWRWKHH[WHUQDOVWDWLFSUHVVXUHRI

瑨攠摵捴祳瑥洠睨敮摪畳瑩湧⁴桥楲ⵦ汯眠潦⁴桥楲慮摬敲

WARNING: Do not operate the air-handler without lters. A portion of the dust

entrained in the air may temporarily lodge in the duct runs and at the supply reg-

isters. Any circulating dust particles could be heated and charred by contact with

the electric heating elements. This residue could soil ceilings, wall, carpets, and

other articles inside the building. Operating the system without a lter will also

allow lint and dirt particles to accumulate on the indoor oil ns and restrict air-

ow through the coil.

!WARNING

Do not, under any circumstances, connect return ductwork to any other

heat producing device such as replace insert, stove, etc. Unauthorized

use of such devices may result in re, carbon monoxide poisoning, explo-

sion, personal injury or property damage.

3.7 REFRIGERANT LINE CONNECTIONS & CHARGING

3.7.1 PREPARATION

7KHFRLOLVVKLSSHGZLWKDORZSUHVVXUHSVLJFKDUJHRIGU\QLWURJHQZKLFKZLOOEH

UHOHDVHGZKHQWKHUXEEHUSOXJVDUHUHPRYHG/HDYHWKHUXEEHUSOXJVLQWKHUHIULJHUDQW

FRQQHFWLRQVWXEVRQWKHDLUKDQGOHUXQWLOWKHUHIULJHUDQWOLQHVDUHUHDG\WREHEUD]HGWR

WKHUHIULJHUDQWFRQQHFWLRQVWXEVWRSUHYHQWFRQWDPLQDQWVIURPHQWHULQJWKHFRLO&OHDQ

WKHHQGVRIWKHWXELQJDQGFRLOFRQQHFWLRQVWXEVLQVLGHDQGRXWVLGHZLWKDQDOFRKRO

ZLSHEHIRUHLQVHUWLQJWKHOLQHVHWWXEHVLQWRWKHFRLOFRQQHFWLRQVWXEVWRDVVXUHDTXDOLW\

OHDNIUHHEUD]HMRLQW

5HIHUWRWKHRXWGRRUXQLWLQVWDOODWLRQLQVWUXFWLRQVIRUGHWDLOVRQUHIULJHUDQWOLQHVL]LQJDQG

LQVWDOODWLRQ

5RXWHWKHUHIULJHUDQWWXELQJLQDPDQQHUWKDQGRHVQRWEORFNVHUYLFHDFFHVVWRWKHIURQW

RIWKHDLUKDQGOHU

3.7.2 CONFIGURING AIR-HANDLER FOR A SINGLE OR DUAL

REFRIGERANT CIRCUITS

$OOPRGHOVDUHSURYLGHGZLWKGXDOFLUFXLWFRLOPDQLIROGVWKDWFDQEH捯湦楧畲敤IRUGXDO

FRQGHQVLQJXQLWDSSOLFDWLRQV7KHFRLOLVFLUFXLWHGWRSURYLGHIXOOIDFHFRLORSHUDWLRQIRU

HDFKV\VWHP.QRFNRXWVDUHSURYLGHGRQERWKVLGHVRIWKHXQLWWRDOORZWKHUHIULJHUDQW

WXELQJWRHQWHUIURPHLWKHUVLGH5HPRYHWKHUXEEHUJURPPHWVIURPWKHSDUWVEDJDQG

LQVWDOOWKHPLQWKHDSSURSULDWHKROHVSULRUWRUXQQLQJWKHOLQHVHWWXELQJLQWRWKHFDELQHW

WRVHDODURXQGDQGSURWHFWWKHWXELQJ&RSSHU晩瑴楮杳DUHSURYLGHGLQWKHSDUWVEDJWR

DOORZWKHWZRUHIULJHUDQWFLUFXLWVWREHWLHGWRJHWKHUIRUVLQJOHFRQGHQVLQJXQLWDSSOLFD

WLRQV7KH晩瑴楮杳PD\EHLQVWDOOHGWRDOORZWKHWXELQJWRHQWHUWKHXQLWIURPHLWKHUVLGH

DVVKRZQLQ)LJXUH

7;9$/9(6

6,1*/(&,5&8,70$1,)2/'

5()5,*(5$17&211(&7,21

(,7+(56,'(

FIGURE 5

3.7.3 REFRIGERANT LINES

7KHIROORZLQJZLOOEHRIKHOSLQDFFRPSOLVKLQJDVXFFHVVIXOLQVWDOODWLRQ

6L]HOLTXLGOLQHIRUQRPRUHWKDQ36,*SUHVVXUHGURS

6L]HVXFWLRQOLQHVIRUQRPRUHWKDQ)ORVVZKLFKFRUUHVSRQGVWRDSSUR[LPDWHO\

36,*SUHVVXUHGURS

:KHQHYDSRUDWRULVLQVWDOOHGEHORZFRQGHQVLQJXQLWGRQRWH[FHHGWKHUHFRPPHQG

HGVXFWLRQOLQH2'7KLVZLOOLQVXUHDGHTXDWHYHORFLWLHVIRUSURSHURLOUHWXUQ

,QVWDOOVWUDLQHUGULHUDQGVLJKWJODVVLQOLTXLGOLQH

3LWFKDOOKRUL]RQWDOVXFWLRQOLQHVGRZQZDUGLQWKHGLUHFWLRQRI晬潷

:KHQPDNLQJXSUHIULJHUDQWSLSLQJWDNHHYHU\SUHFDXWLRQWRSUHYHQWGLUWDQGPRLV

WXUHIURPHQWHULQJWKHSLSLQJ

/RFDWHWKHFRQGHQVLQJXQLWDQGHYDSRUDWRUVDVFORVHWRJHWKHUDVSRVVLEOHWRPLQL

PL]HSLSLQJUXQV

$OLTXLGOLQHVROHQRLGLQVWDOOHGMXVWDKHDGRIWKHH[SDQVLRQYDOYHLVUHFRPPHQGHG

6HHWDEOHVEHORZIRUJHQHUDOUHIULJHUDQWOLQHVL]LQJDQGHTXLYDOHQWOHQJWKRIYDOYHV

慮搠晩瑴楮杳

5HIHUWRWKHYDSRUDQGOLTXLGOLQHVHOHFWLRQSURFHGXUHDQGFKDUWVLQWKHRXWGRRUXQLW

LQVWDOODWLRQPDQXDORUOLWHUDWXUHIRUPRUH獰散楦楣UHIULJHUDQWOLQHVL]LQJLQIRUPDWLRQ

:KHQGXDORXWGRRUXQLWVDUHPDWFKHGZLWKWKHDLUKDQGOHUXVLQJGXDOFLUFXLWVVL]H

WKHUHIULJHUDQWOLQHVIRUHDFKV\VWHPLQGHSHQGHQWO\

3.7.4 LIQUID LINE FILTER DRIER

$QHZOLTXLG晩汴敲GULHUPXVWEHLQVWDOOHGHYHU\WLPHDQ\SDUWRIWKHV\VWHPKDVEHHQ

RSHQWRWKHDWPRVSKHUHHYHQLILW¶VIRUDVKRUWSHULRGRIWLPH7KH晩汴敲GULHUVKRXOGEH

LQVWDOOHGFORVHWRWKHDLUKDQGOHUIRUDV\VWHPVWDUWHGXSLQWKHFRROLQJPRGHDQGQHDU

WKHRXWGRRUXQLWIRUDKHDWSXPSV\VWHPVWDUWHGXSLQWKHKHDWLQJPRGH7KLVDOORZVWKH

晩汴敲GULHUWRFDWFKDQ\FRQWDPLQDQWVLQWKHOLTXLGOLQHEHIRUHWKH\FDQHQWHUWKHLQGRRURU

RXWGRRU7;9LQOHWVFUHHQ$晩汴敲GULHUPXVWEHLQVWDOOHGLQWKHOLTXLGOLQHRIHDFKFLUFXLW

IRUGXDOFLUFXLWDSSOLFDWLRQV

EQUIV.

LENGTH TO

EVAP. (FT.)

LIQUID

LINE O.D.

SUCTION

LINE O.D.

10 [35kW]

0-50 [0-15m] 5/8 [26mm] 1 3/8 [35mm]

51-100 [16-30m] 5/8 [26mm] 1 5/8 [41mm]

101-150 [31-46m] 5/8 [26mm] 1 5/8 [41mm]

3.7.5 BRAZING

$LULQVLGHWKHWXELQJDQGFRLOVKRXOGEHGLVSODFHGZLWKGU\QLWURJHQSULRUWRWKHEUD]LQJ

SURFHVVWRSUHYHQWWKHIRUPDWLRQRIKDUPIXOFRSSHUR[LGHLQVLGHWKHWXELQJ,WLVYHU\

LPSRUWDQWQRWWRSUHVVXUL]HWKHV\VWHPZLWKQLWURJHQZKLOHEUD]LQJRUSLQKROHOHDNVZLOO

IRUPLQWKHEUD]HMRLQW7KLVLVDFFRPSOLVKHGE\UHPRYLQJWKHJDXJHSRUWYDOYHFRUHRQ

RQHRIWKHRXWGRRUXQLWVHUYLFHYDOYHVWRDOORZWKHSUHVVXUHWREHUHOLHYHGDVWKHKHDW

HGQLWURJHQH[SDQGV)LOOWKHV\VWHPZLWKGU\QLWURJHQWKURXJKWKHRWKHUVHUYLFHYDOYH

条畧攠灯牴湤⁴桥渠瑵牮⁴桥楴牯来渠晬潷晦畳琠扥景牥牡穩湧猠扥杵渮

3URWHFWWKH7;9¶VDQGRXWGRRUXQLWVHUYLFHYDOYHVIURPRYHUKHDWLQJXVLQJDZHWUDJRU

KHDWVLQNFRPSRXQG/HDYHWKHZHWUDJRUKHDWVLQNPDWHULDOLQSODFHXQWLOWKHMRLQWDQG

VXUURXQGLQJWXELQJFRROVGRZQWRDVDIHWHPSHUDWXUH'RXEOHWLSWRUFKHVFDQKHOSPLQ

LPL]HEUD]LQJWLPHDQGKHDWFRQGXFWLRQWRWKHKHDWVHQVLWLYHFRPSRQHQWVLIWKH晬慭攠LV

WXUQHGGRZQDQGKHOGRQWKHMRLQWMXVWORQJHQRXJKWRPDNHWKHEUD]HMRLQW:LWKERWK

VLQJOHDQGGRXEOHWLSWRUFKHVWXUQLQJWKH晬慭攠XSWRRPXFKDQGNHHSLQJWKH晬慭攠RQ

WKHMRLQWWRRORQJZLOOGDPDJHWKHKHDWVHQVLWLYHFRPSRQHQWVHYHQZKHQDZHWUDJRU

KHDWVLQNFRPSRXQGLVXVHG

3.7.6 LEAK TESTING

$IWHUDOOEUD]HMRLQWVDUHFRPSOHWHGUHSODFHWKHYDOYHFRUHUHPRYHGZKHQSXUJLQJZLWK

QLWURJHQDQGWKHQOHDNWHVWWKHV\VWHPE\SUHVVXUL]LQJWRSVLJZLWKGU\QLWURJHQDQG

DOORZWKHV\VWHPWRVLWIRUDWOHDVWPLQXWHVORQJHULISRVVLEOHWRDVVXUHWKHSUHVVXUH

GRHVQRWGURS

3.7.7 EVACUATION

,IQROHDNVDUHGHWHFWHGRSHQWKHRXWGRRUXQLWVHUYLFHYDOYHVIRURXWGRRUXQLWVVKLSSHG

ZLWKDQLWURJHQKROGLQJFKDUJHDQGHYDFXDWHWKHV\VWHPGRZQWRPLFURQVRUEHORZ

EHIRUHFKDUJLQJWKHV\VWHP)DLOXUHWRUHDFKPLFURQVRIYDFXXPLVDVLJQRID

OHDNRUH[FHVVLYHPRLVWXUHLQVLGHWKHV\VWHP)RURXWGRRUXQLWVVKLSSHGFKDUJHGZLWK

5$GRQRWRSHQWKHVHUYLFHYDOYHVXQWLOWKHHYDFXDWLRQSURFHVVLVFRPSOHWH

3.7.8 REFRIGERANT CHARGING

2QFHWKHHYDFXDWLRQSURFHVVLVFRPSOHWHGEUHDNWKHYDFXXPZLWKWKHUHIULJHUDQWIURPD

UHIULJHUDQWF\OLQGHURUZLWKUHIULJHUDQWVWRUHGLQWKHRXWGRRUXQLWE\RSHQLQJWKHRXWGRRU

XQLWVHUYLFHYDOYHVLIWKHRXWGRRUXQLWLVFKDUJHGZLWK5$7KHFKDUJLQJSURFHVV

FDQQRWEHFRPSOHWHGXQWLOWKHUHPDLQLQJVWHSVLQWKHLQVWDOODWLRQSURFHVVDUHFRPSOHWHG

慮搠瑨攠楮摯潲楲ⵦ汯眠楳摪畳瑥搠瑯WKHSURSHUOHYHO6HH6HFWLRQIRUIXUWKHUGHWDLOV

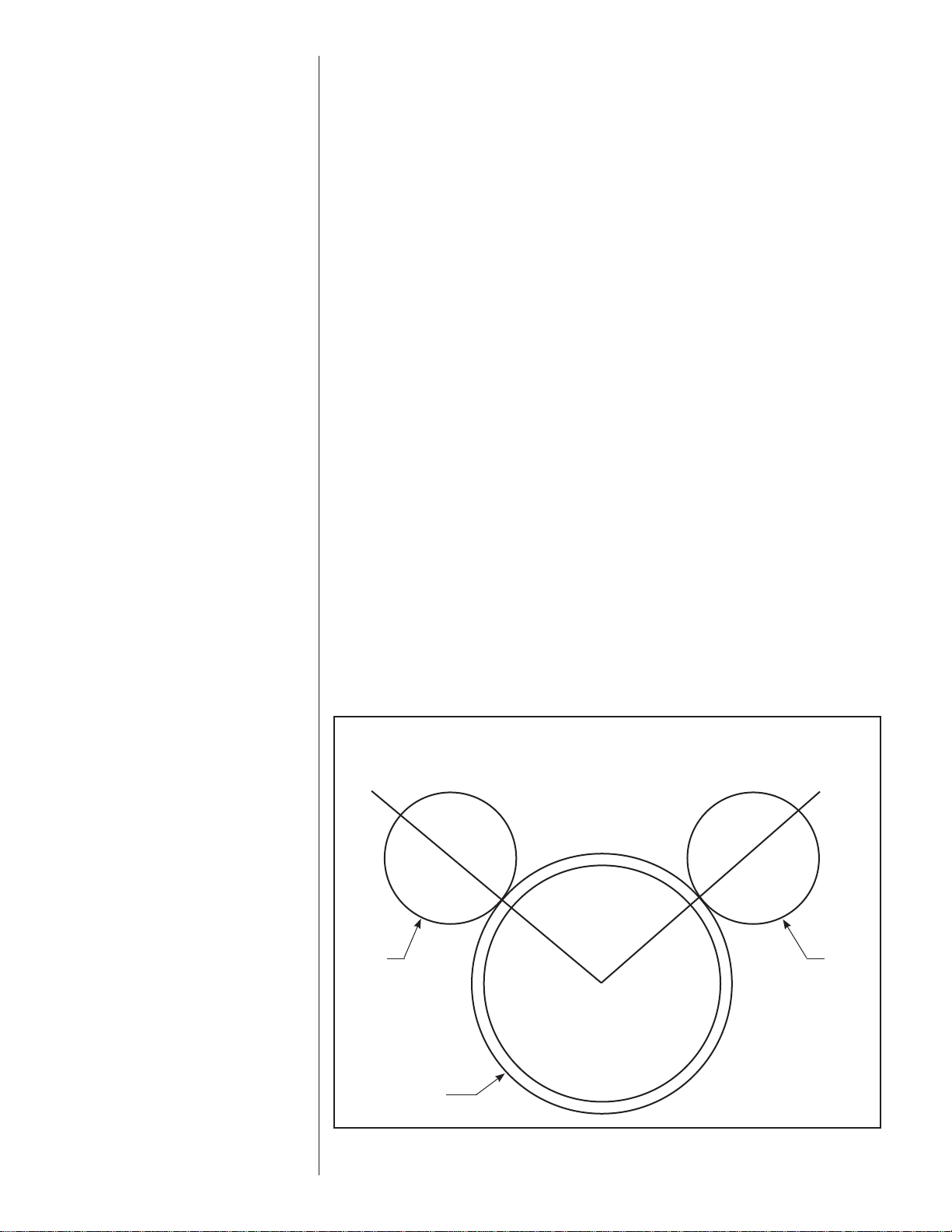

3.8 TXV SENSING BULB ATTACHMENT

IMPORTANT: '2127SHUIRUPDQ\EUD]LQJZLWKWKH7;9EXOEDWWDFKHGWRWKHYDSRU

OLQH$IWHUEUD]LQJRSHUDWLRQVKDYHEHHQFRPSOHWHGDQGWKHWXELQJKDVFRROHGWRWKH

WRXFKFODPSHDFK7;9EXOEVHFXUHO\RQDKRUL]RQWDOVHFWLRQRILWVFRUUHVSRQGLQJYDSRU

OLQHDWWKHWRR¶FORFNSRVLWLRQVHH)LJXUHZLWKWKHVWUDSSURYLGHGLQWKHSDUWVEDJ

FIGURE 6

BULB LOCATION – HORIZONTAL SECTION OF VAPOR LINE

2¶&/2&. 2¶&/2&.

7;9

%8/%

9$325/,1(

7;9

%8/%

3.9 CONDENSATE DRAIN

7ZRGUDLQFRQQHFWLRQVDUHSURYLGHGRQHRQHDFKVLGHRIWKHXQLW3OXJWKHXQXVHG

GUDLQFRQQHFWLRQXVLQJWKHSOXJSURYLGHGLQWKHSDUWVEDJ

䍯湳畬琠汯捡氠捯摥猠潲牤楮慮捥猠景爠獰散楦楣敱畩牥浥湴献

IMPORTANT: :KHQPDNLQJGUDLQ晩瑴楮朠FRQQHFWLRQVWRWKHGUDLQSDQXVHDWKLQOD\HURI

呥晬潮⁰慳瑥Ⱐ獩汩捯湥爠呥晬潮⁴慰攠慮搠楮獴慬氠桡湤⁴楧桴

IMPORTANT: :KHQPDNLQJGUDLQ晩瑴楮朠FRQQHFWLRQVWRGUDLQSDQGRQRWRYHUWLJKWHQ

佶敲瑩杨瑥湩湧楴瑩湧猠捡渠獰汩琠灩灥潮湥捴楯湳渠瑨攠摲慩渠灡渮

,QVWDOOGUDLQOLQHVVRWKH\GRQRWEORFNVHUYLFHDFFHVVWRIURQWRIWKHXQLW0LQLPXP

捬敡牡湣攠潦′㐠楮捨敳猠牥煵楲敤潲楬瑥爬潩氠潲汯睥爠牥浯癡氠慮搠獥牶楣攠慣捥獳

,WLVUHFRPPHQGHGWKDWWKHDLUKDQGOHUFDELQHWEHSLWFKHGVOLJKWO\GRZQZDUGWRZDUGWKH

SULPDU\GUDLQFRQQHFWLRQWRDVVXUHWKHFRQGHQVDWHGUDLQVFRPSOHWHO\IURPWKHGUDLQ

SDQ7KHGRZQZDUGSLWFKVKRXOGEHDSSUR[LPDWHO\´SHUIRRWDQGLQERWKD[HV

'RQRWUHGXFHGUDLQOLQHVL]HOHVVWKDQFRQQHFWLRQVL]HSURYLGHGRQFRQGHQVDWHGUDLQ

SDQ

$OOGUDLQOLQHVPXVWEHSLWFKHGGRZQZDUGDZD\IURPWKHXQLWDPLQLPXPRI´SHU

IRRWRIOLQHWRHQVXUHSURSHUGUDLQDJH

'RQRWFRQQHFWFRQGHQVDWHGUDLQOLQHWRDFORVHGRURSHQVHZHUSLSH5XQFRQGHQ

VDWHWRDQRSHQGUDLQRURXWGRRUV

7KHGUDLQOLQHVKRXOGEHLQVXODWHGZKHUHQHFHVVDU\WRSUHYHQWVZHDWLQJDQGGDPDJH

GXHWRFRQGHQVDWHIRUPLQJRQWKHRXWVLGHVXUIDFHRIWKHOLQH

0DNHSURYLVLRQVIRUGLVFRQQHFWLQJDQGFOHDQLQJRIWKHSULPDU\GUDLQOLQHVKRXOGLW

EHFRPHQHFHVVDU\,QVWDOODLQWUDSLQWKHSULPDU\GUDLQOLQHDVFORVHWRWKHXQLWDV

SRVVLEOH0DNHVXUHWKDWWKHWRSRIWKHWUDSLVEHORZFRQQHFWLRQWRWKHGUDLQSDQWR

DOORZFRPSOHWHGUDLQDJHRISDQ6HH)LJXUH

3OXJWKHXQXVHGGUDLQFRQQHFWLRQZLWKWKHSOXJSURYLGHGLQWKHSDUWVEDJXVLQJDWKLQ

污祥爠潦⁴敦汯渠灡獴攬楬楣潮攠潲⁴敦汯渠瑡灥⁴漠景牭⁷慴敲⁴楧桴敡氮

7HVWWKHFRQGHQVDWHGUDLQSDQDQGGUDLQOLQHDIWHULQVWDOODWLRQLVFRPSOHWH3RXUZDWHU

LQWRGUDLQSDQHQRXJKWR晩汬GUDLQWUDSDQGOLQH&KHFNWRPDNHVXUHGUDLQSDQLV

GUDLQLQJFRPSOHWHO\QROHDNVDUHIRXQGLQGUDLQOLQH晩瑴楮杳ⰠDQGZDWHULVGUDLQLQJIURP

WKHRSHQHQGRIWKHSULPDU\GUDLQOLQH

3.10 THERMOSTAT

6HHLQVWUXFWLRQVIRUWKHFRQGHQVLQJXQLWRUKHDWSXPSIRUUHFRPPHQGHGURRPWKHUPRVWDWV

&KRRVHDQDSSURSULDWHWKHUPRVWDWIRUWKHDSSOLFDWLRQ

7KHWKHUPRVWDWVKRXOGEHPRXQWHGWRIHHWDERYHWKH晬潯爠RQDQLQVLGHZDOORI

WKHFRQGLWLRQHGVSDFHRUDKDOOZD\WKDWKDVJRRGDLUFLUFXODWLRQIURPWKHRWKHUURRPV

EHLQJFRQWUROOHGE\WKHWKHUPRVWDW,WLVHVVHQWLDOWKDWWKHUHEHIUHHDLUFLUFXODWLRQDW

WKHORFDWLRQRIWKHVDPHDYHUDJHWHPSHUDWXUHDVRWKHUURRPVEHLQJFRQWUROOHG0RYH

PHQWRIDLUVKRXOGQRWEHREVWUXFWHGE\IXUQLWXUHGRRUVGUDSHULHVHWF7KHWKHUPRVWDW

VKRXOGQRWEHPRXQWHGZKHUHLWZLOOEHDIIHFWHGE\GUDIWVKRWRUFROGZDWHUSLSHVRUDLU

GXFWVLQZDOOVUDGLDQWKHDWIURP晩牥灬慣攬ODPSVWKHVXQ79RUDQRXWVLGHZDOO6HH

LQVWUXFWLRQVKHHWSDFNDJHGZLWKWKHUPRVWDWIRUPRXQWLQJDQGLQVWDOODWLRQLQVWUXFWLRQV

FIGURE 7

CONDENSATE DRAIN TRAP

67$

3.11 ELECTRICAL WIRING

)LHOGZLULQJPXVWFRPSO\ZLWKWKH1DWLRQDO(OHFWULF&RGH&(&LQ&DQDGDDQGDQ\

DSSOLFDEOHORFDORUGLQDQFH

3.11.1 POWER WIRING

,WLVLPSRUWDQWWKDWSURSHUHOHFWULFDOSRZHULVDYDLODEOHIRUFRQQHFWLRQWRWKHXQLWPRGHO

EHLQJLQVWDOOHG6HHWKHXQLWQDPHSODWHZLULQJGLDJUDPDQGHOHFWULFDOGDWDLQWKHLQVWDOOD

WLRQLQVWUXFWLRQV

,QVWDOODFLUFXLWGLVFRQQHFWRIDGHTXDWHVL]HORFDWHGZLWKLQVLJKWRIDQGUHDGLO\DFFHV

VLEOHWRWKHXQLW

• IMPORTANT: 8QLWVZLWKHOHFWULFKHDWHUNLWVLQVWDOOHGPD\EHHTXLSSHGZLWKRQHRU

PRUHEUDQFKFLUFXLWIXVHV7KHVHIXVHVSURWHFWWKHLQWHUQDOZLULQJLQWKHHYHQWRID

VKRUWFLUFXLW

6XSSO\FLUFXLWSRZHUZLULQJPXVWEH&PLQLPXPFRSSHUFRQGXFWRUVRQO\6HH(OHF

WULFDO'DWDLQ6HFWLRQVDQGIRUDPSDFLW\ZLUHVL]HDQGFLUFXLWSURWHFWRU

UHTXLUHPHQW6XSSO\FLUFXLWSURWHFWLYHGHYLFHVPD\EHHLWKHUIXVHVRUFLUFXLWEUHDNHUV

3.11.1.1 NO-HEAT APPLICATIONS

,IHOHFWULFKHDWLVQRWLQVWDOOHGFRQQHFWWKHLQFRPLQJOLQHYROWDJHZLUHVWRWKHOLQHYROWDJH

WHUPLQDOEORFN7%LQVLGHWKHDLUKDQGOHUFRQWUROER[

3.11.1.2 ELECTRIC HEAT APPLICATIONS

,IDQ5;+(HOHFWULFKHDWHUNLWLVLQVWDOOHGWKHEORZHUPRWRUFRQWDFWRULVSURYLGHGLQWKH

KHDWHUNLWZLWKOHDGVWKDWPXVWEHURXWHGWRWKHDLUKDQGOHUFRQWUROER[DQGFRQQHFWHGWR

WKHOLQHYROWDJHWHUPLQDOEORFN7%LQVLGHWKHDLUKDQGOHUFRQWUROER[

IMPORTANT:7KHYDULDEOHVSHHG'ULYH9)'PXVWWRSRZHUHGFRQWLQXRXVO\DQGFRQ

WUROOHGE\WKHWKHUPRVWDWVLJQDOVWRSUHYHQWSUHPDWXUHIDLOXUHRIWKH9)'

7KHUHIRUHWKHEORZHUPRWRUSRZHUVXSSO\OHDGVIURPWKHEORZHUFRQWDFWRUORFDWHGLQ

WKH5;+(HOHFWULFKHDWNLWPXVWEHPRYHGIURPWKHORDGVLGHRIWKHEORZHUFRQWDFWRU

777WRWKHOLQHVLGHRIWKHEORZHUFRQQHFWRU///

3.11.2 GROUNDING

7KLVSURGXFWPXVWEH獵晦楣楥湴汹JURXQGHGLQDFFRUGDQFHZLWK1DWLRQDO(OHFWULFDO

&RGH&(&LQ&DQDGDDQGDQ\DSSOLFDEOHORFDORUGLQDQFH

*URXQGLQJPD\EHDFFRPSOLVKHGE\JURXQGLQJPHWDOFRQGXLWZKHQLQVWDOOHGLQDFFRU

GDQFHZLWKHOHFWULFDOFRGHVWRWKHXQLWFDELQHW

*URXQGLQJPD\DOVREHDFFRPSOLVKHGE\DWWDFKLQJJURXQGZLUHWRJURXQGOXJSURYLG

HGLQWKHDLUKDQGOHUFRQWUROER[

WARNING

The unit must be permanently grounded. Failure to do so can result in electri-

cal shock causing personal injury or death.

!

This manual suits for next models

5

Table of contents

Popular DC Drive manuals by other brands

Power Electronics

Power Electronics SD700 Series Applications manual

Trane

Trane TR200 Series operating instructions

Siemens

Siemens SINAMICS G115D operating instructions

Siemens

Siemens SINAMICS G120 CU240B-2 operating instructions

Danfoss

Danfoss VLT AutomationDrive FC 360 Programming guide

GFA

GFA ELEKTROMAT SG 50F installation instructions

YASKAWA

YASKAWA GPD 315/V7 Technical manual

ABB

ABB +Q951 user manual

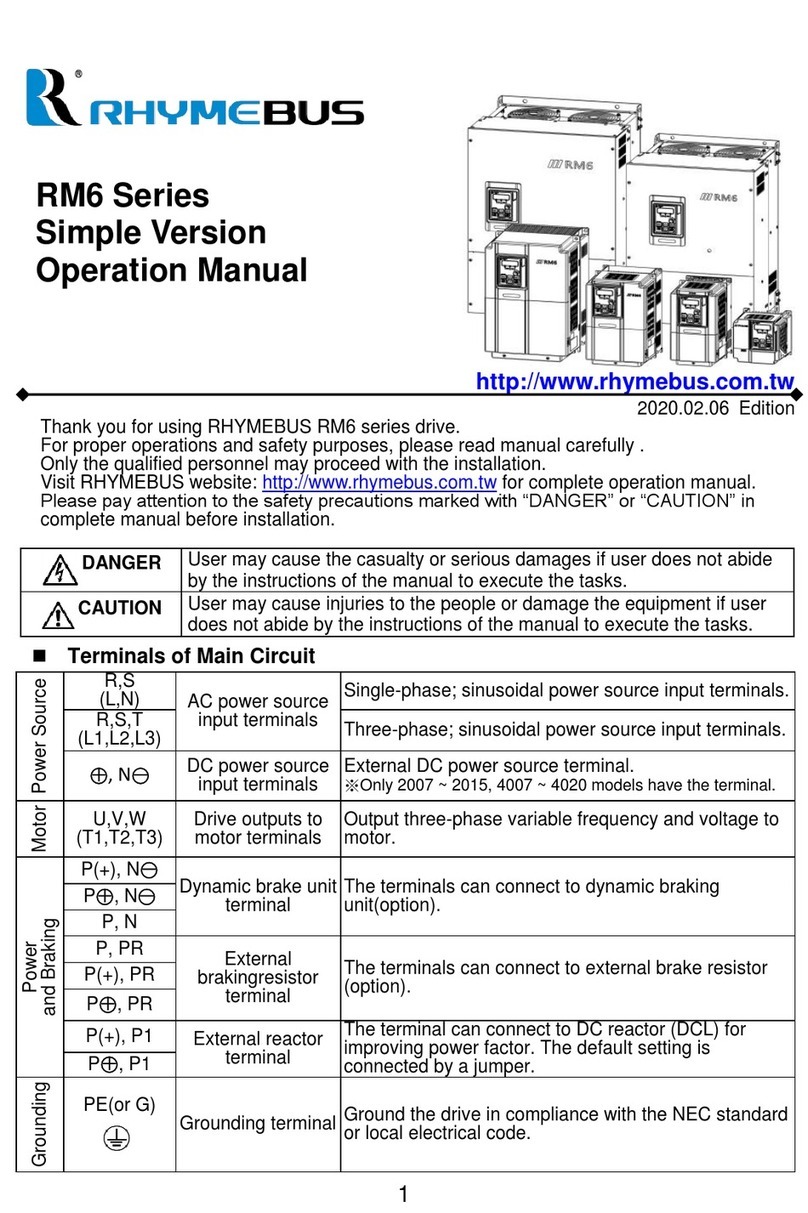

Rhymebus

Rhymebus RM6 Series Operation manual

Graham

Graham 1703 Series Installation, operation and maintenance manual

LUST DRIVETRONICS

LUST DRIVETRONICS FLP Series Service instructions

Oriental motor

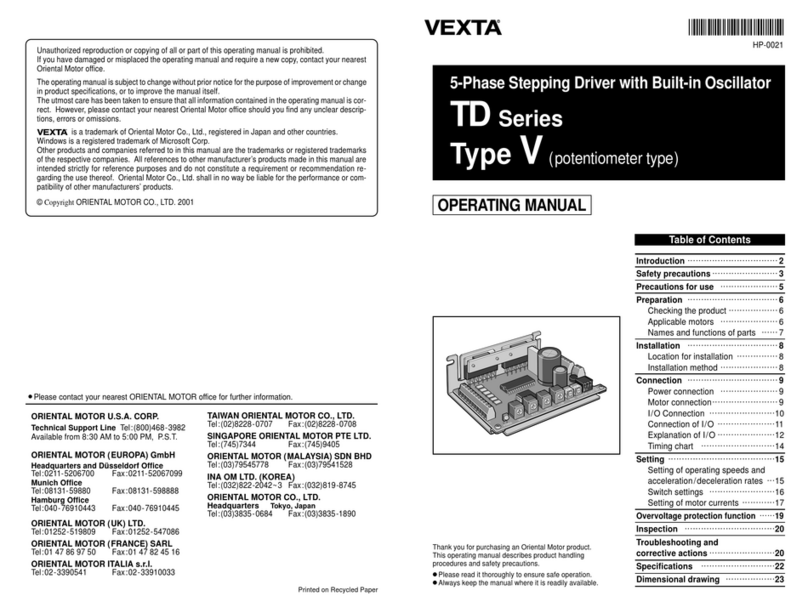

Oriental motor VEXTA TD Series operating manual