Page 2

Before beginning the cabinet installation, you will need to

apply the finished overlays to the side (s) of the cabinet or run of

cabinets that will be exposed to the room. Just follow the below

simple steps to apply the flush fit end panels.

Materials:

Finished Flush Fit End Panel, Roll of Double Sided Tape

(Suggest 1 roll per flush fit end panel) or construction

adhesive. (Neither are provided.)

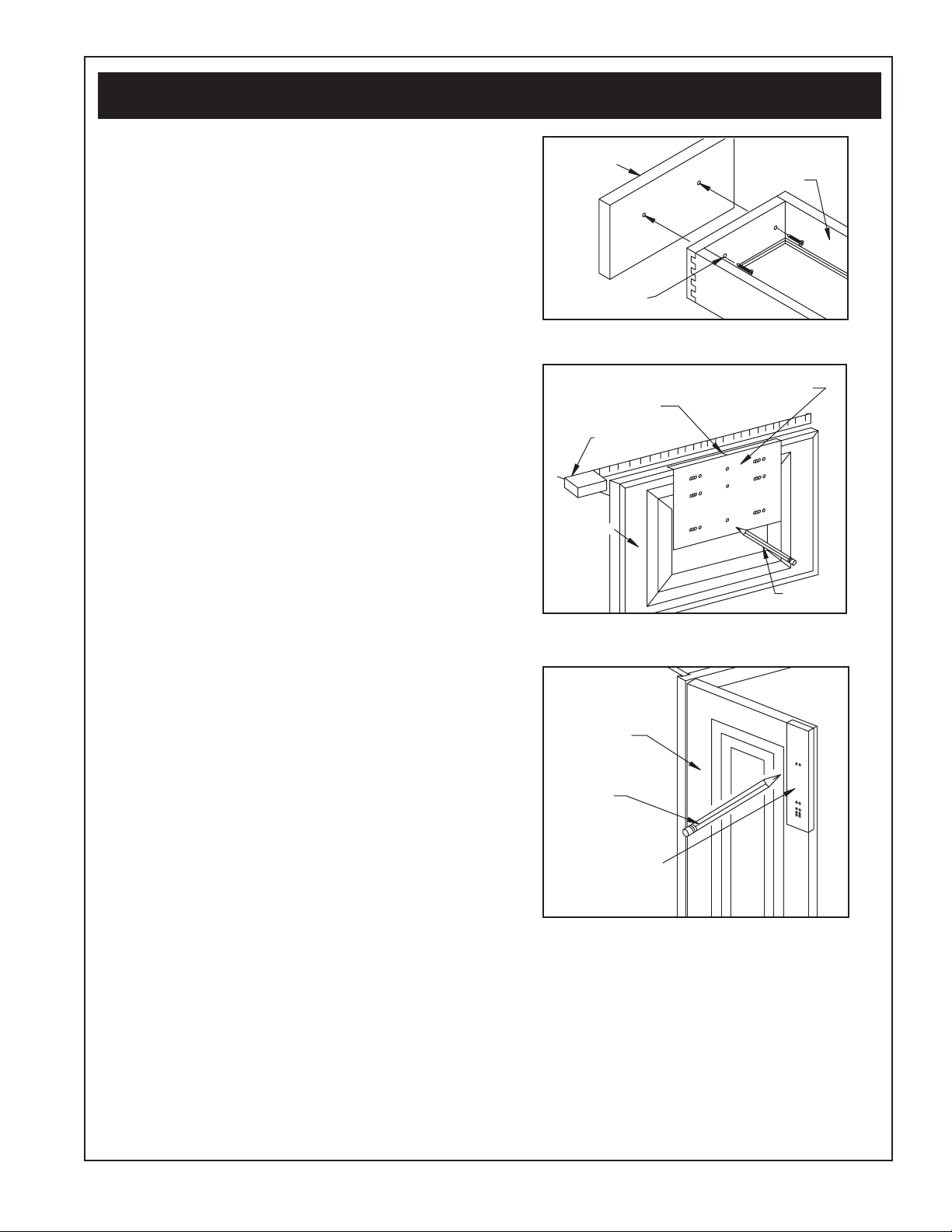

Toe Notch Instructions

Note: If flush fit end panel is on the left side of cabinet, the toe

notch will be on the right side of the flush fit end panel. If the flush

fit end panel is for the right side of the cabinet, the toe notch will

be on the left side of the flush fit end panel.

Toe notch out the flush fit end panel.

a) Line up the bottom of toe notch with the bottom of

the overlay

b) Using a pencil draw a line along the edge of the

toe notch

c) Using a jigsaw or hand saw, cut along the line.

Make sure the saw blade is inside the toe notch

area, which will be removed.

d) Any left over pencil marks can be erased with a

pencil eraser.

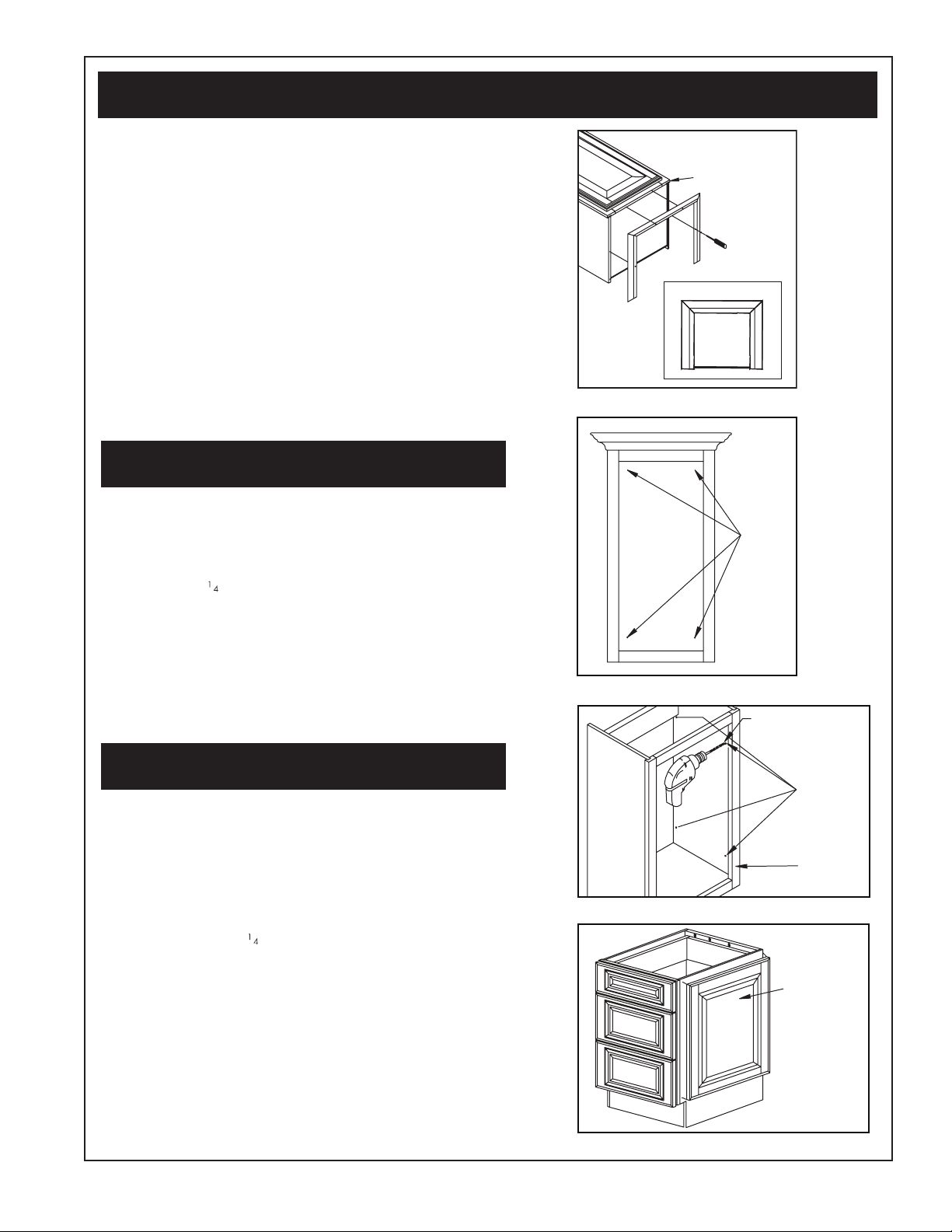

1. Cut and apply double sided tape to flush fit end panel or

use construction adhesive (Figure 2). If using construction

adhesive, use tape guidelines as glue guideline and then

move to Step #2.

a) Cut the roll of double sided tape into strips. Cut

tape strips to the lengths and quantities listed on the

tape template. You will need approximately one

roll of tape for each flush fit end panel.

b) Apply the tape to the flush fit end panel following

the tape template diagram. Tape strips applied

along the edges of the flush fit end panel should be

1/4” from the edge.

c) As you apply each tape strip, run your finger along

the strip, applying pressure to make sure the tape

makes complete contact with the flush fit end panel.

2. Apply flush fit end panel to cabinet side panel

a) Remove the backer from each tape strip.

b) Holding the flush fit end panel at an angle from the

cabinet side panel, slide the front edge of the flush

fit end panel into the face frame groove. Make sure

the entire edge of the flush fit end panel is seated

inside the face frame groove.

c) Align the top of the flush fit end panel with the top

of the cabinet side panel and press the flush fit end

panel against the side panel.

d) Working from front to back, apply pressure along

the entire surface of the flush fit end panel to make

sure each tape/adhesive strip makes complete

contact with the cabinet side panel.

e) Allow the tape/adhesive to cure for 1 hour before

proceeding with the cabinet installation.

Step 2. Flush Fit End Panel Application Instructions

NOTE: TAPE/ADHESIVE SHOULD BE APPLIED 1/4” FROM EDGES OF FLUSH FIT END PANEL.

Strip/

Adhesive

LEFT

SIDE

RIGHT

SIDE

Strip/

Adhesive

Strip/

Adhesive

Strip/

Adhesive

Strip/

Adhesive

Strip/

Adhesive

Strip/Adhesive

Strip/Adhesive

Strip/Adhesive

Strip/Adhesive

Figure 2