Contents

1.

Specifications ...............................................................................................................................................2

2.

Required Operational Condition....................................................................................................................2

3.

Installation....................................................................................................................................................2

3.1 Location.............................................................................................................................................3

3.2 Connection of the power cord and grounding......................................................................................3

4.

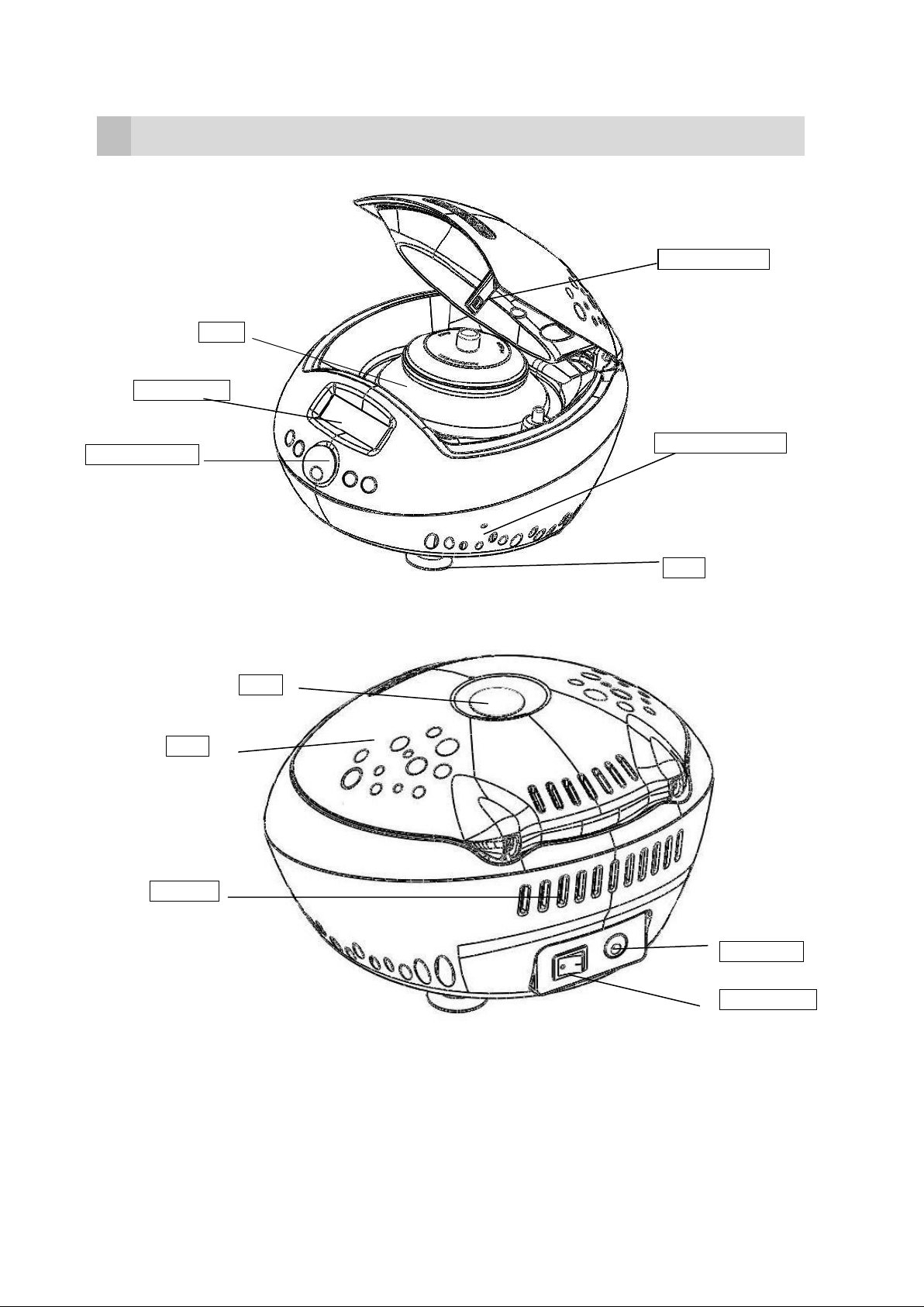

Structure....................................................................................................................................................... 4

5.

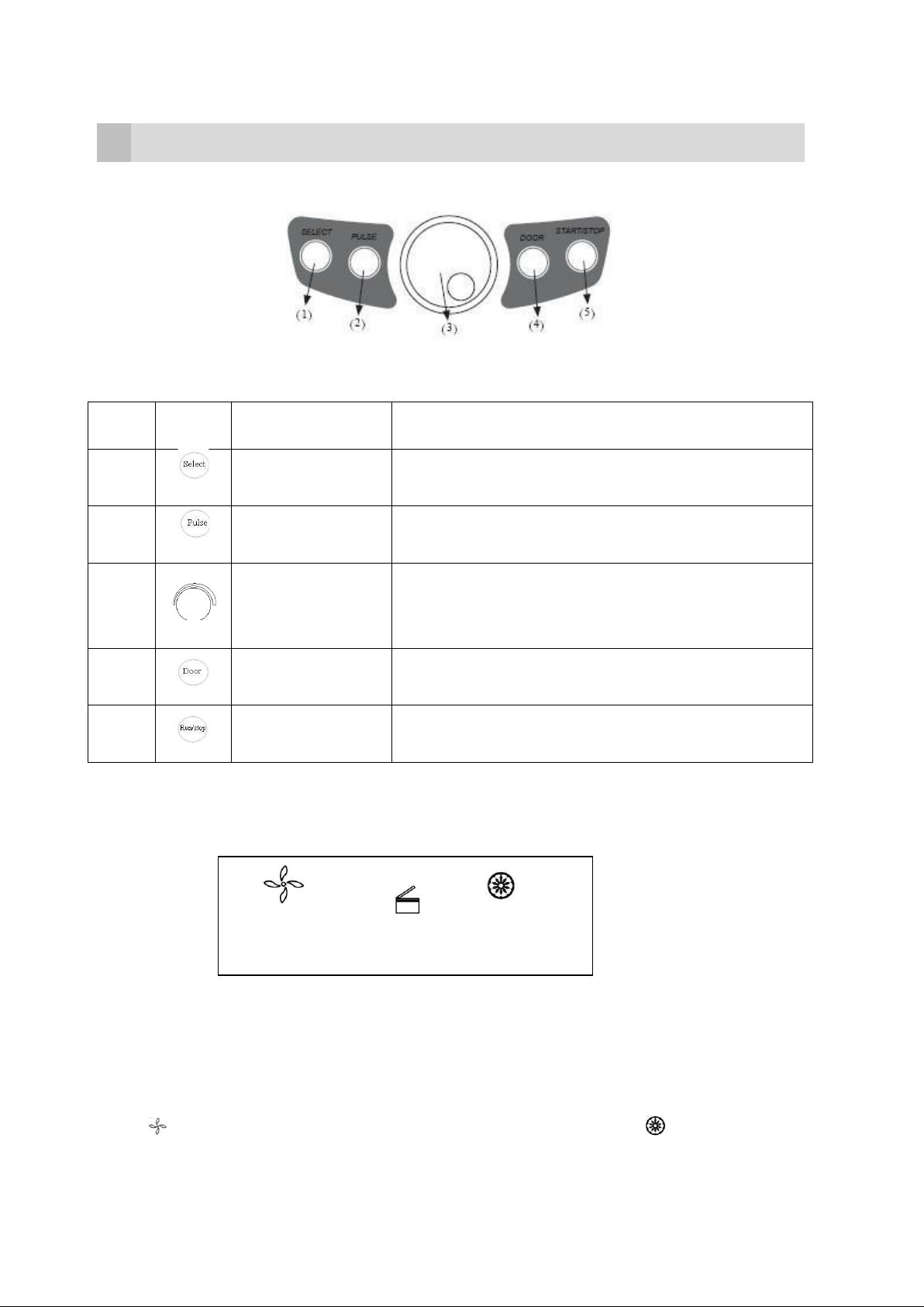

Operation panel.............................................................................................................................................5

6.

Rotor Preparation..........................................................................................................................................6

6.1 Prepare the samples.............................................................................................................................6

6.2 Inject the samples into tubes...............................................................................................................6

6.3 Keep the tubes balance........................................................................................................................6

6.4 Inspect the rotor .................................................................................................................................. 6

6.5 Symmetrically load centrifuge tubes in rotor........................................................................................ 6

7.

Operation......................................................................................................................................................7

7.1 Normal Operation ............................................................................................................................... 7

7.2 RCF Operation.................................................................................................................................. 10

7.3 Pulse Operation................................................................................................................................. 10

8.

Maintenance ............................................................................................................................................... 10

9.

Troubleshooting.......................................................................................................................................... 12

9.1 Frequent problems list....................................................................................................................... 12

9.2 How to open the door........................................................................................................................ 13

10.

Instructions of rotor and tube..................................................................................................................... 14

10.1 The rotor instructions................................................................................................................... 14

10.2 Tubes........................................................................................................................................... 16

11.

Calculation Relative Centrifuge Force(RCF)........................................................................................ 18