The German testing authority BG, recommends the

following minimum for the bolt lengths:

1.0 x M in steel (minimum quality S235JR [1.0037])

≈AS3678 GR250.

1.25 x M (thread diameter) in cast iron (e.g. GG 25)

2 x M (thread diameter) in aluminium

2.5 x M (thread diameter) in light alloys of low strength

(M = thread size/diameter, e.g. M20)

• When lifting light metals, nonferrous metals and gray cast

iron the thread has to be chosen in such a way that the

WLL of the thread corresponds to the requirements of the

base material.

• The min. quality of the hexagon bolt of the VWBG-V must

be class 10.9 according to EN 24014 (DIN 931) with correct

nominal diameter.

• RUD supplies the Vario length complete with a washer and

crack-detected nut corresponding to DIN EN ISO 7042

(DIN 980) or will be supplied with a crack inspected collar

nut acc. to DIN 6331 or 2 x crack inspected hex nuts Class

8 AS1112.1 with washer.

• The position of the lifting points must be carried out in such

be avoided.

• For single leg lifts, the lifting point should be vertically

above the centre of gravity of the load.

• For two leg lifts, the lifting points must be equidistant to/

or above the centre of gravity of the load.

• For three and four leg lifts, the lifting points should be

arranged symmetrical around the centre of the gravity, in

the same plane if possible.

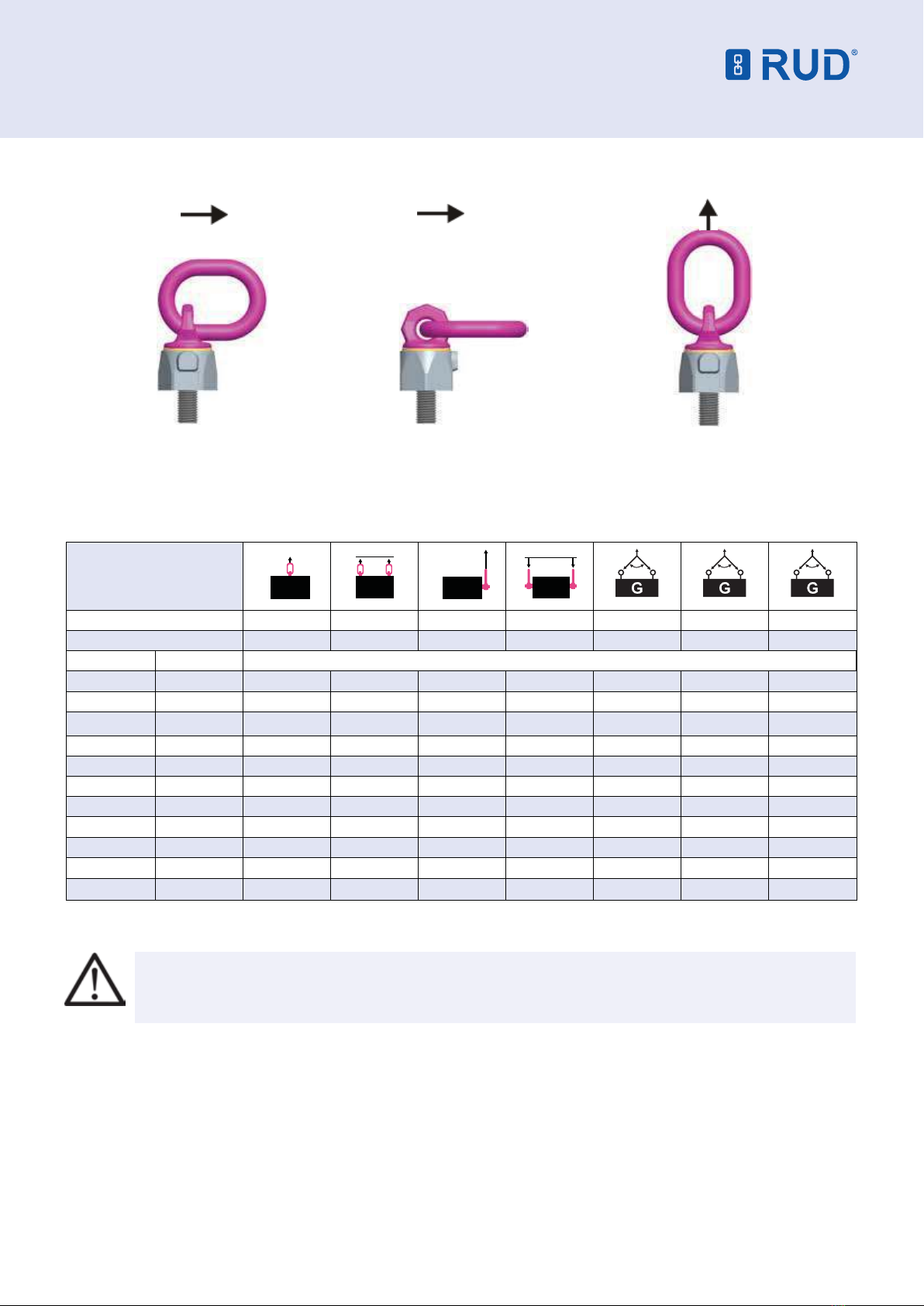

Load Symmetry: The working load limit of individual RUD

lifting points are calculated using the following formula and

are based on symmetrical loading:

NOTE: For WLL Calculations

• ß angle is taken from the vertical plane.

• Included angle is the angle between the sling legs.

Number of load bearing legs is as follows:

Symetrical Unsymetrical

2/3/4 leg 2 1

Load bearing legs (compare also with table 1)

• When lifting points are used in a multileg assembly, care

should be taken to calculate the WLL (Working Load Limit)

due to the deration caused by forces acting in multiple

directions. The reduction in WLL (Working Load Limit)

for multileg assemblies should be checked with relevant

Standards e.g. AS 3775.2:2014 Chain slings for lifting

purposes - Grade T(80) and V(100) - Care and use.

• The lifting points should be mounted in such a way that

they may easily be accessed for inspection and assembly/

disassembly of the sling.

VWBG-V LOAD RING

User Instructions - Part 2

1. Safety Instructions

ATTENTION: Please inspect all lifting points

prior to use. Damage, incorrect assembly or

improper use may result in serious injuries

and/or material damage.

• Not suitable for permanent turning operations under load.

Lifting point cannot be turned to 90° from the bolt-on

direction under full load.

• The ball bearing must not be disassembled.

• The load ring must not be free to articulate.

• RUD VWBG-V lifting points must only be used by instructed

and competent persons considering BGR 500 / DGUV 100-

statutory regulations.

2. Intended use of VWBG-V

RUD VWBG-V lifting points must only be used for the assembly

at the load or at lifting means.

They are intended to be bolted into the payload and can be

turned under load, but not under full load, especially not in the

90° direction. Not suitable for permanent turning operations

under load.

RUD VWBG-V lifting points can also be used as lashing points

to attach lashing means.

If the lifting points are used exclusively for lashing the value

of the WLL (working load limit) can be doubled. LC (lashing

capacity) = 2 x WLL.

RUD VWGB-V lifting points must only be used in the hereby

described operation purpose.

Before installing and every use, visually inspect RUD lifting

points, with particular attention to any evidence of corrosion,

wear and weld cracks and deformations. Please ensure

compatibility of bolt thread and tapped hole.

3. Assembly and Instruction Manual

3.1 General Information

• Temperature range:

Usage at higher temperatures is not recommended due to

necessary, the working load limit (WLL) of the VWBG-V

must be reduced as follows:

-40°C up to 100°C no reduction

100°C up to 200°C minus 15 %

200°C up to 250°C minus 20 %

250°C up to 350°C minus 25 %

Temperatures exceeding 350°C are prohibited!

Please pay attention when using DIN EN 7042 (DIN 980)

nuts the max. operation temperature of 150°C (acc. to DIN

EN ISO 2320).

• RUD VWBG-V lifting points must not be used with

aggressive chemicals such as acids, alkaline solutions and

their vapours.

3.2 Hints for the assembly

• The material construction to which the lifting point will be

attached should be of adequate strength to withstand forces

during lifting without deformation.

WLL = required of lifting point/individual leg (kg)

G = load weight (kg)

n = number of load bearing legs

ß = angle of inclination of the individual leg

WLL = G

n x cos ß