6 REVT-05ERV

VI - BASIC OPERATING MODES

A. ENERGY RECOVERY MODE

continuously with one supplying the required VOLUME

of fresh outdoor air, and the other exhausting an equal

VOLUME of stale indoor air returned from the conditioned

space. Energy Recovery is achieved by slowly rotating

the Energy Recovery Wheel within its cassette framework,

known as the Energy Recovery Cassette, or ERC.

Duringwinter operationtheERC absorbsheat and moisture

from the return air stream during one half of a complete

revolution and recovers that energy by transferring it to

the cold, dryer outdoor air during the other half of the

same revolution. The process automatically reverses for

summer operation when heat and moisture are absorbed

from the fresh, outdoor supply air and transferred to the

return air stream being exhausted. This transfer of energy

This mode of operation allows outdoor air ventilation

rates to be increased by a factor of three or more without

cooling systems.

B. TEMPERING MODE

Neutral Air Option - Also available are cooling and

heating options installed after the ERC to further temper

the supply air to achieve a space neutral condition. This is

an ideal solution for applications requiring 100% outdoor

air.

Neutral Air Plus Option - If a cooling capacity beyond

that required to achieve a space neutral condition is

desired there is an option available that will meet that

requirement. This will provide a solution for applications

requiring 100% outdoor air, plus meet an additional

cooling load. See supplemental brochure for cooling

performance with matching condensing unit.

C. HOW IT WORKS

The ERC contains an Enthalpy Wheel that is a new

concept in rotary air-to-air heat exchangers. Designed as

a packaged unit for ease of installation and maintenance,

the standard unit (without optional features) requires only

the connection of electrical power to make the system

operational. The Enthalpy Wheel is coated with a Silica

Gel Desiccant using a patented and proprietary process

developed by the wheel manufacturer that permanently

bonds it to the polymer substrate without adhesives.

Even after years of operation and repeated washings, the

desiccant remains in place.

Silica Gel is a highly porous solid adsorbent material

that structurally resembles a rigid sponge. Water vapor

pressures; which drives water molecules into/from the

desiccant cavities to transfer moisture from the more

humid air stream to the dryer air stream.

Enthalpy is a term representing total heat energy, meaning

sensible heat energy plus latent heat energy. Sensible

and latent heat are the two components of total heat.

Sensible heat is the energy contained in dry air and can

a given VOLUME of air. While latent heat is the energy

contained in the water vapor within moist air.

During the summer cooling season the latent heat can

only be removed by condensing that vapor below its dew

point with the optional cooling coil (water or refrigerant)

the moist supply air stream and then transferring it to the

dryer return air stream, which exhausts it to the outside.

For buildings that require a large amount of outside air to

meet ventilation codes, this greatly reduces the cooling

load on the air conditioning system. An additional load

reduction can be achieved if the unit contains the optional

Tempering Coil.

In the winter heating season this vapor transfer capability

works to increase moisture in the supply air stream by

absorbing it from the return air. This reduces the amount

occupied space during the heating season. Since the

Enthalpy Wheel transfers moisture entirely in the vapor

phase, the wheel remains dry eliminating wet surfaces

that retain dust and promote fungal growth. Because it

is always dry and constantly rotating between the supply

and exhaust air streams, which reverses the direction of

When the outdoor air temperatures are below 15°F, it is

recommended to use the optional Low Ambient Kit

VII - RECEIVING and INSPECTION

Do not attempt to operate the unit if there is indication that

any part or control has been under water. Any control or

component that has been under water must be replaced

prior to start-up.

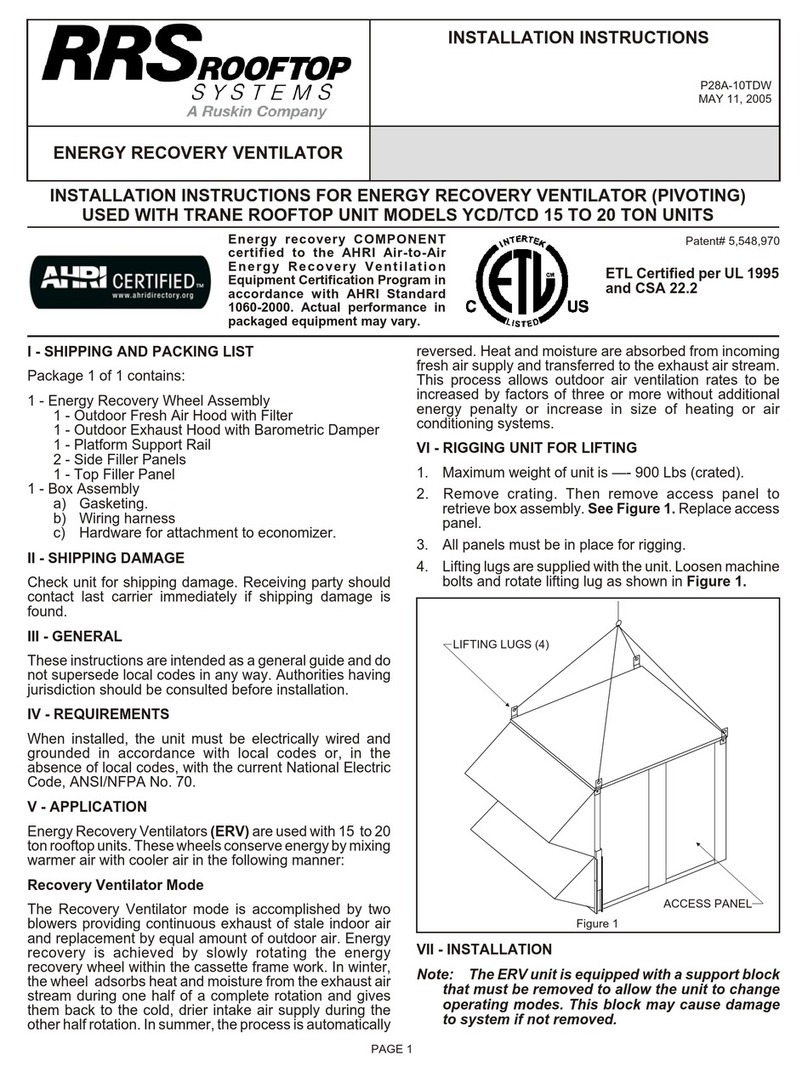

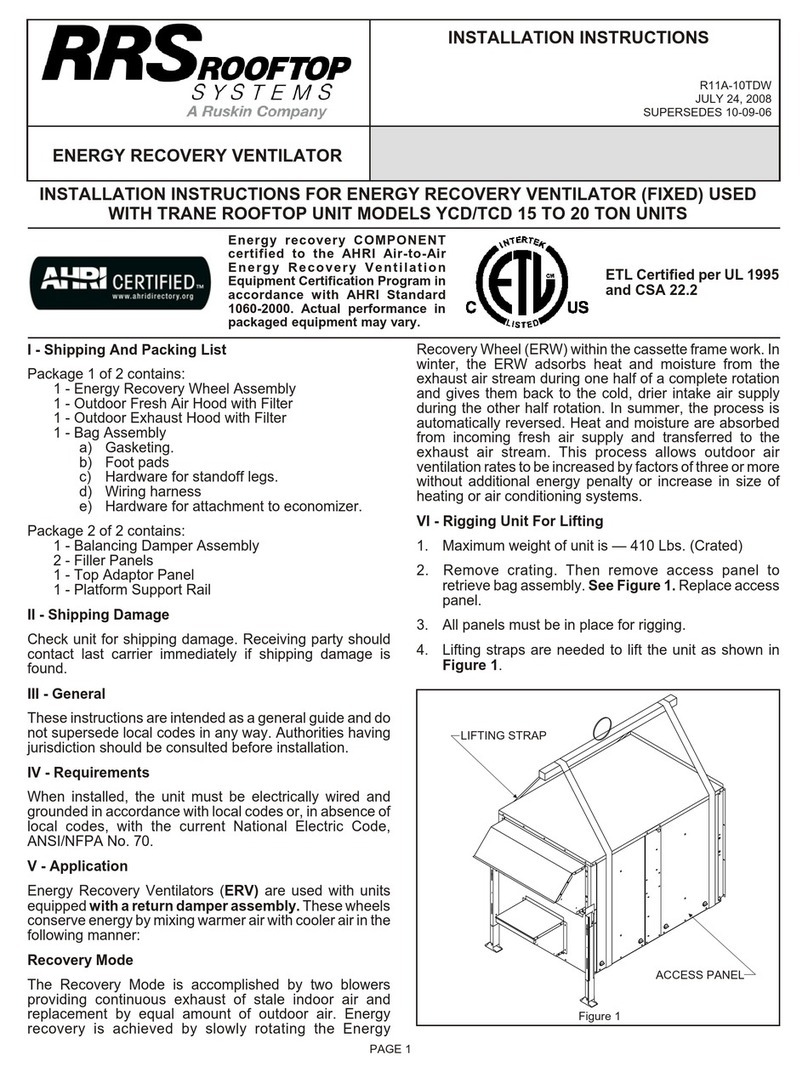

A. SHIPPING and PACKING LIST

1. Assembled ERV

2. Assembled Exhaust Hood

Inside ERV behind door marked:

"Filter Access-Exhaust."

3. Disassembled Intake Hood

Inside ERV behind door marked:

"Filter Access-Supply."

4. Flue Vent Hood (Gas Post-Heat Option)

Inside ERV behind door marked:

"Filter Access-Supply."

NOTE: The EVT 09/-19 will have Hoods attached

before shipping, remove during rigging for lifting if

they obstruct the lifting straps and reinstall after the

unit is set on its curb.

B. SHIPPING DAMAGE

The ERV is thoroughly inspected and test run at the

factory. Nevertheless, damage may occur during shipping

and handling; therefore, upon delivery, inspect the unit for

both obvious and hidden damage, and ensure all options/

accessories items are present.

Additional inspection steps:

CAUTION

Danger of sharp metallic edges. Can cause injury.

Take care when servicing unit to avoid accidental

contact with sharp edges.