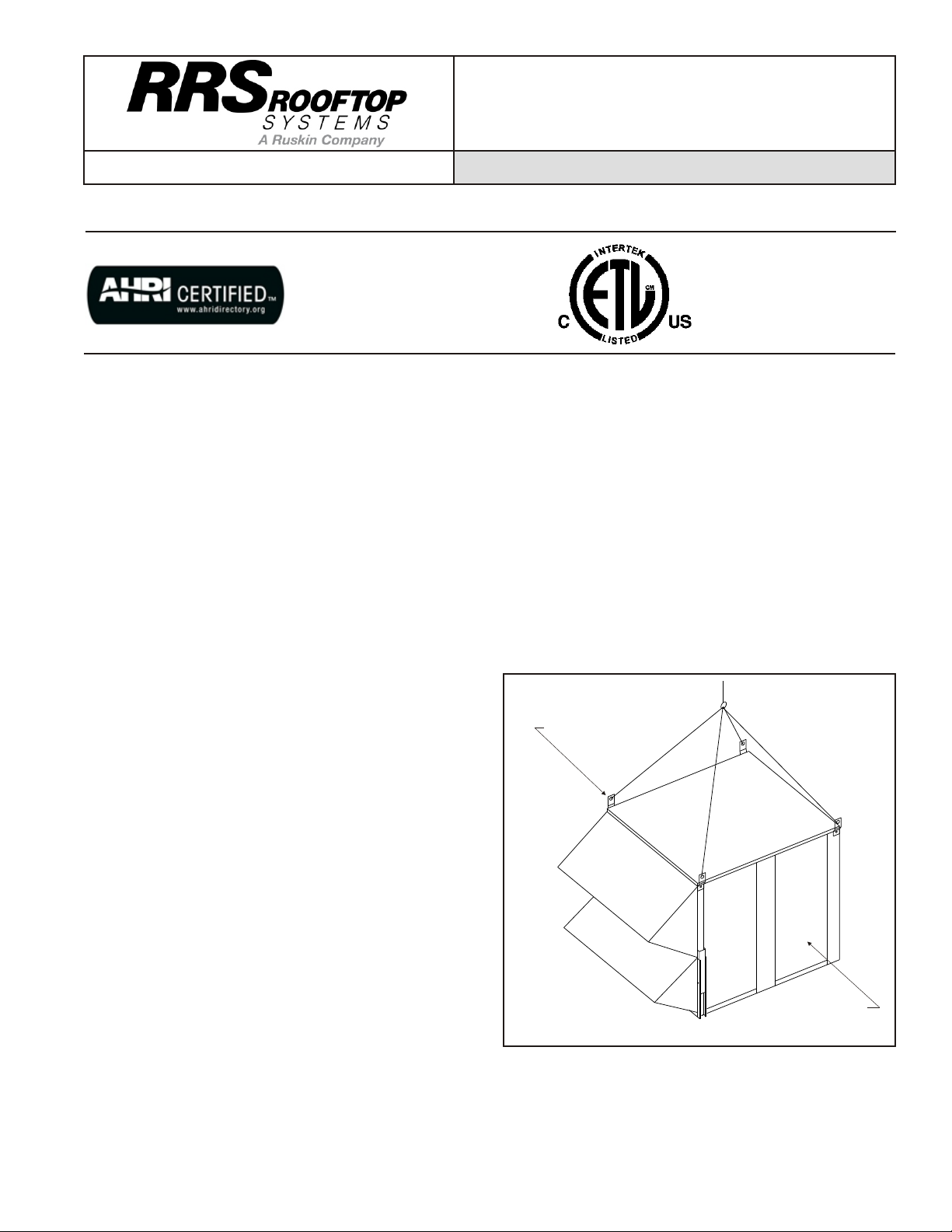

consists of a unique rotary energy recovery wheel that

rotates in and out of fresh air streams within a heavy duty,

permanently installed blower cabinet that provides ready

access to all internal components. The media is polymeric

material that is coated and permanently bonded with a dry

desiccant for total enthalpy recovery. The wheel is belt

driven by PSC motor and drive belt.

When slowly rotating through counter flowing exhaust and

fresh air streams the ERV adsorbs sensible heat and latent

heat from the warmer air stream and transfer this total

energy to the cooler air stream during the second half of its

rotating cycle. Rotating at 60 revolutions per minute, the

wheel provides constant flow of energy from warmer to

cooler air stream. The large energy transfer surface and

laminar flow through the wheel causes this constant flow

of recovered energy to represent up to 85% of the

difference in total energy contained within the two air

streams.

Sensible and latent heat are the two components of total

heat. Sensible heat is energy contained in dry air and latent

heat is the energy contained within the moisture of the air.

The latent heat load from the outdoor fresh air on an air

conditioning system can often be two to three times that of

the sensible heat load and in the winter it is a significant

part of a humidification heat load.

During both the summer and winter, the ERV transfers

moisture entirely in the vapor phase. This eliminates wet

surfaces that retain dust and promote fungal growth as well

as the need for a condensate pan and drain to carry water.

Because it is constantly rotating when in the air stream, the

ERV is always being cleared by air, first in one direction

then the other. Because it is always dry, dust or other

particles impinging on the surface during one half cycle,

are readily removed during the next half cycle.

Low Ambient Kit is appropriate for climates with limited

HVAC system operation when outdoor temperatures are

below 15oF.

The frost threshold is the outdoor temperature at which

frost will begin to form on the ERV wheel. For energy

recovery ventilators, the frost threshold is typically below

15oF. Frost threshold is dependent on indoor temperature

and humidity. The table shows how the frost threshold

temperatures vary depending on indoor conditions.

FROST THRESHOLD TEMPERATURE

INDOOR RH AT

70oF

FROST THRESHOLD

TEMPERATURE

20% 0oF

30% 5oF

40% 10oF

Because Energy Recovery Ventilators have a low frost

threshold, frost control options are not necessary in many

climates. Where outdoor temperatures may drop below

the frost threshold during the ERV operational hours,

exhaust only frost control option is available.

Low Ambient Kit

Low Ambient Kit turns off the supply blower when outdoor

temperatures fall below the frost threshold. Exhaust Only

set points are field adjustable with a factory supplied

thermostat. Supply fan operation is automatically restored

when the exhaust air temperature rises above the

thermostat set point. Provisions for introducing make-up

air into the building when the supply blower is off to avoid

depressurization should be considered.

PAGE 3

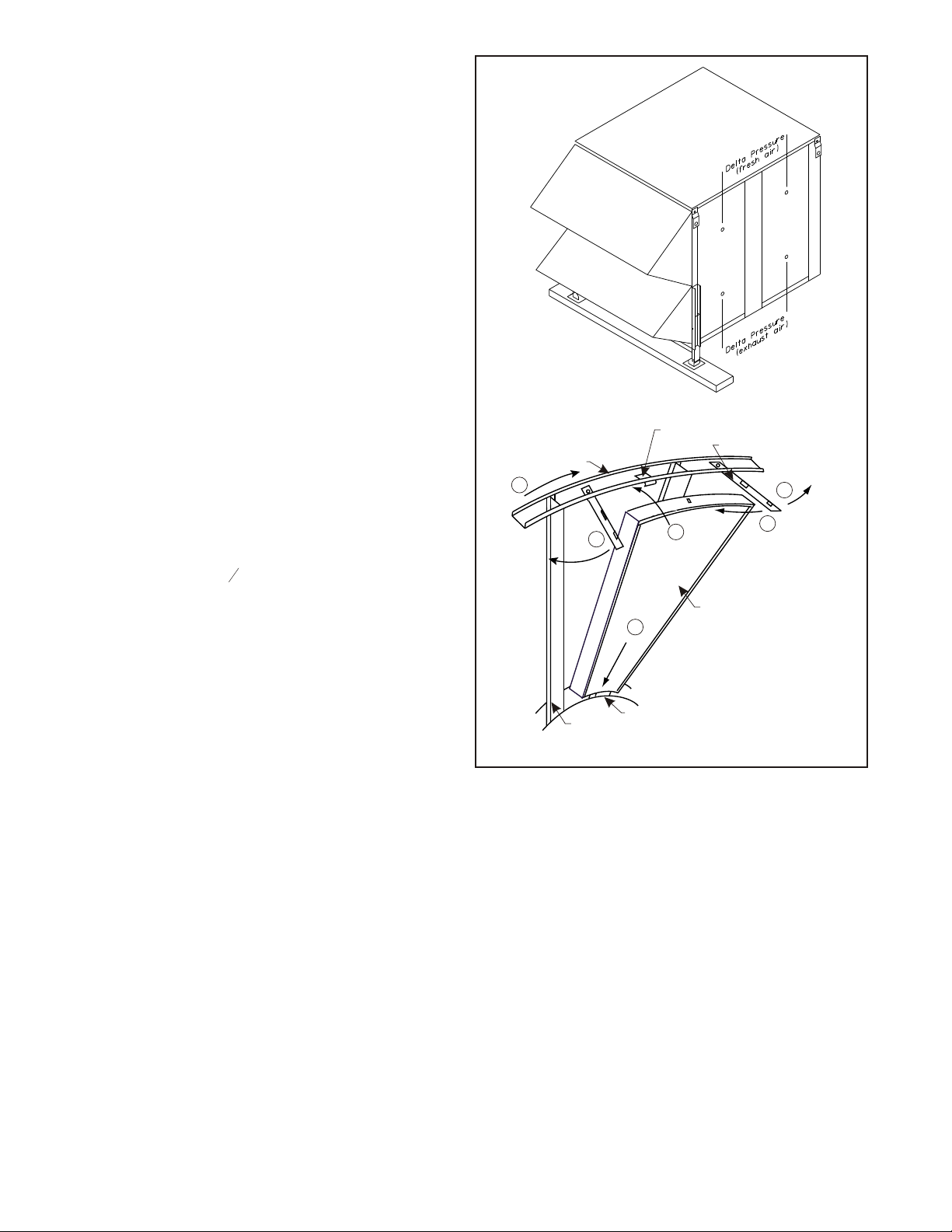

Recovery Mode

On a thermostat call for blower operation in heating,

cooling or continuous blower, the ERW will rotate between

fresh air and exhaust air streams. Both the fresh air and

exhaust air blowers will also be operating to overcome the

air resistance of the ERV. See Figure 3.

RECOVERY MODE

Figure 3

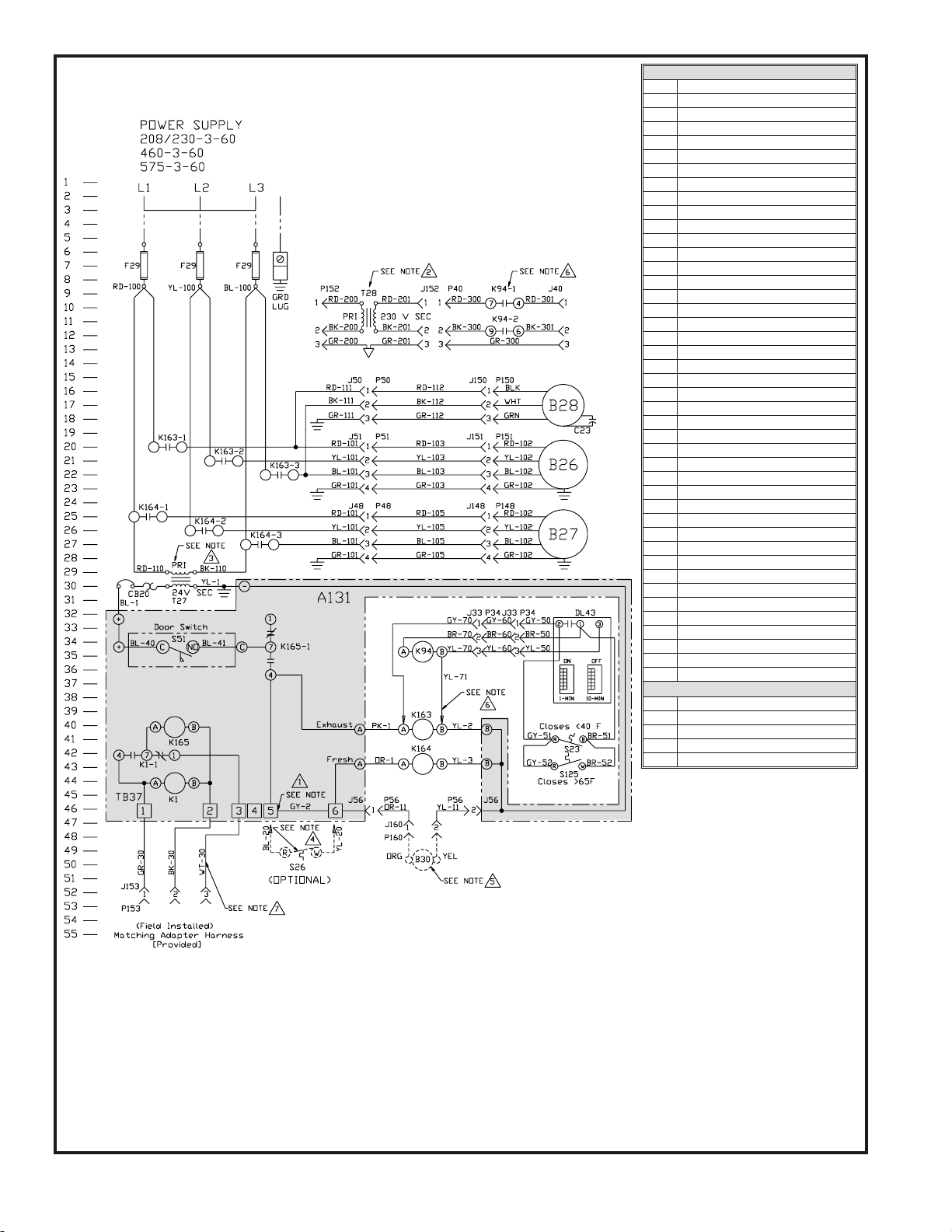

IX - SYSTEM CHECK

1. Disconnect main power.

2. Turn thermostat to "Cont" for blower operation.

3. Restore power to unit. Observe ERV wheel rotation

and both fresh air and exhaust air blowers will

operating.

Note: If Low ambient kit is used the jumper between

TB37-5 & TB37-6 should be removed. Also if

system check out is being conducted at low

ambient temperatures, technician should be

aware that this kit can cause system not to

operate.

4. Verify that the ERV (3) three phase blower motors are

phased sequentially ensuring correct rotation and

operation.

a) Disconnect power.

b) Reverse any two field power leads to the ERV.

c) Reapply power.

A - Return Damper Settings

Manually adjust position of dampers. This is accomplished

by loosing and tightening set screw on positioning rod.

B - Blower Speed Adjustment

Blower speed selection is accomplished by changing the

sheave setting on both fresh air and exhaust air blowers.

Both blowers are factory set at "closed" for maximum

airflow. To determine air flow setting, external static

pressure readings will need to be read across the ERV.

See Figure 4 for location to take pressure readings.

1. Disconnect main power to unit before making

adjustment to economizer and/or ERV unit.

2. Replace ERV control access cover.