16. Insert and secure top filler panel under top flange of

rooftop unit and against top flange of ERV.

17. Seal, if required, along face (top and sides) of ERV unit

where it meets rooftop unit to insure no air leakage.

18. Locate the enthalpy control sensor removed earlier

from the rooftop unit. Remove the connectors and

wires from its terminals.

19. Remove the screws to the top panel of the fresh air

hood on the ERV labeled "filter access". Push up the

top panel and remove the air filter. Reinstall the

enthalpy control sensor with self-tapping screws on

the right side panel of the fresh air intake hood.

20. Remove the ERV access panels. Locate the bundle of

wires on the top deck. Route the blue and purple wires

to the enthalpy control sensor. Connect the purple wire

to the "+" terminal on the enthalpy control and the blue

wire to the "S" terminal. See field wiring diagram.

21. Remove ERV support block to allow wheel rotation

when unit is placed in operation.

22. All electrical connections must conform to any local

codes and current National Electric Codes (NEC) and

Canadian Electric Codes (CEC). Refer closely to unit

wiring diagram in unit and/or in these instructions for

proper wiring connections. Refer to the unit nameplate

for minimum circuit ampacity and maximum

overcurrent protection size. Electrical data is listed on

unit rating plate and motor nameplates.

23. Connect line voltage power to ERV from rooftop unit

disconnect switch through the knock out. Connect the

line voltage to the ERV control box per the wiring

diagram.

24. Ground unit with a suitable ground connection either

through unit supply wiring or earth ground.

Note: Unit voltage entries must be sealed weather

tight after wiring is complete.

25. Replace access panels onto the ERV unit and secure.

26. Restore power to unit.

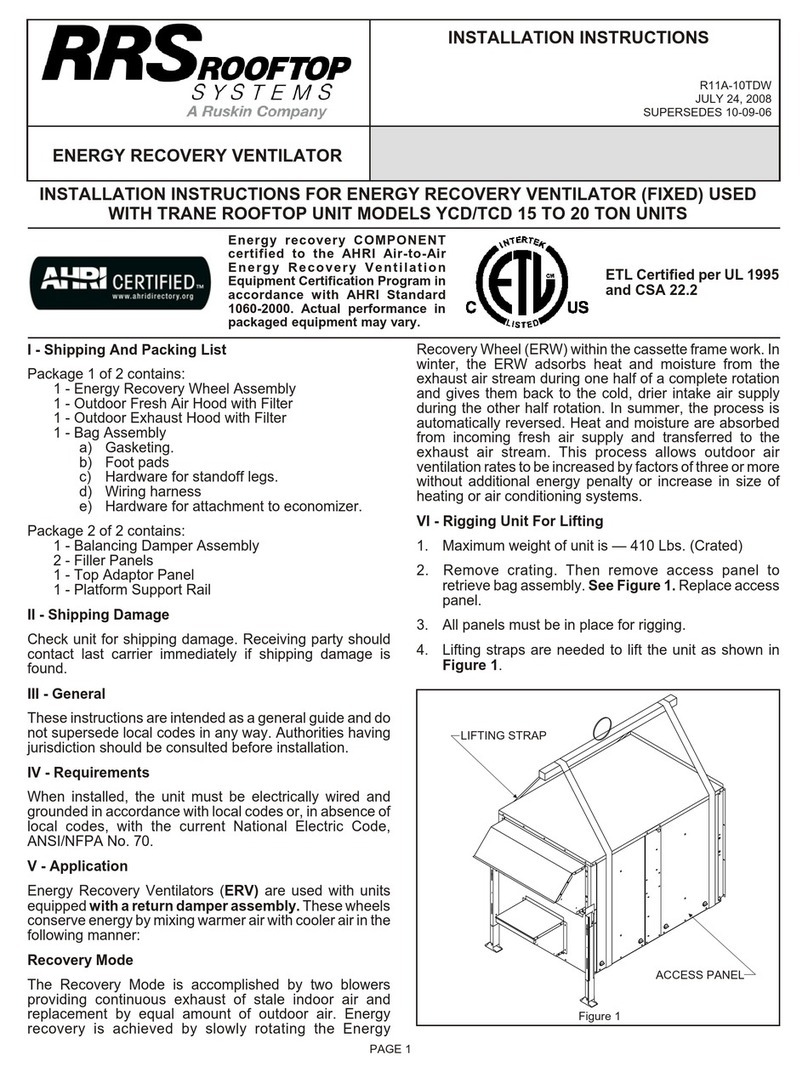

27. Balancing is done by removing the plastic plugs in

door panels (4 total).

28. With a manometer measure pressure drop [ inches of

water column] across the top half of ERV (top holes in

door panel). Unit CFM is determined by referring to

Table #1. If CFM values are not per design, adjust

internal damper setting inside rooftop unit. This

accomplished by loosing set screw on damper frame

of positioning rod or slide damper. The repeat

measurement method.

29. Place plastic plugs back into door panels

30. Cleanup once ERV is operating properly. Caulk any

open joints, holes or seams to make the unit

completely air and water tight.

31. Leave this instruction manual with owner or in an

envelope to be kept near the unit.

PAGE 3

VIII - OPERATION

How It Works

The unit contains an Energy Recovery Wheel (ERW) that

is a new concept in rotary air-to-air heat exchanger.

Designed as a packaged unit for ease of installation and

maintenance, only matching up to rooftop unit with an

internal economizer and connection of electrical power is

required to make the system operational. The concept

consists of a unique rotary energy recovery wheel that

rotates in and out of fresh air streams within a heavy duty,

permanently installed blower cabinet that provides ready

access to all internal components. The media is polymeric

material that is coated and permanently bonded with a dry

desiccant for total enthalpy recovery. The wheel is belt

driven by PSC motor and drive belt.

When slowly rotating through counter flowing exhaust and

fresh air streams the ERV adsorbs sensible heat and latent

heat from the warmer air stream and transfer this total

energy to the cooler air stream during the second half of its

rotating cycle. Rotating at 60 revolutions per minute, the

wheel provides constant flow of energy from warmer to

cooler air stream. The large energy transfer surface and

laminar flow through the wheel causes this constant flow

of recovered energy to represent up to 85% of the

difference in total energy contained within the two air

streams.

Sensible and latent heat are the two components of total

heat. Sensible heat is energy contained in dry air and latent

heat is the energy contained within the moisture of the air.

The latent heat load from the outdoor fresh air on an air

conditioning system can often be two to three times that of

the sensible heat load and in the winter it is a significant

part of a humidification heat load.

During both the summer and winter, the ERV transfers

moisture entirely in the vapor phase. This eliminates wet

surfaces that retain dust and promote fungal growth as well

as the need for a condensate pan and drain to carry water.

Because it is constantly rotating when in the air stream, the

ERV is always being cleared by air, first in one direction

then the other. Because it is always dry, dust or other

particles impinging on the surface during one half cycle,

are readily removed during the next half cycle.

Low Ambient Kit is appropriate for climates with limited

HVAC system operation when outdoor temperatures are

below 15oF.

The frost threshold is the outdoor temperature at which

frost will begin to form on the ERV wheel. For energy

recovery ventilators, the frost threshold is typically below

15oF. Frost threshold is dependent on indoor temperature

and humidity. The table shows how the frost threshold

temperatures vary depending on indoor conditions.

FROST THRESHOLD TEMPERATURE

INDOOR RH AT

70oF

FROST THRESHOLD

TEMPERATURE

20% 0oF

30% 5oF

40% 10oF

Because Energy Recovery Ventilators have a low frost

threshold, frost control options are not necessary in many

climates. Where outdoor temperatures may drop below

the frost threshold during the ERV operational hours,

exhaust only frost control option is available.