)LJ6HWXS

6ZLWFKHVIRU

6WDQGDUG

5DQJH8QLWV

6HOHFW287387

6HOHFW5$1*(

,IXQLWLVRUGHUHGZLWKD&XVWRP5DQJH

WKHQWKHVZLWFKPXVWEHVHWWR5

&KRRVH',5(&7,21

%LGLUHFWLRQDOLVDSOXVPLQXVUDQJHVR

FKRRVLQJ´UDQJHLV´WR´%LGLUHFWLRQDO

DQG´WR´8QLGLUHFWLRQDO

&KRRVH81,76,QFKHV:&RU3$6&$/6

&KRRVH5(63216(7,0(

)DVW5HVSRQVH VHFRQG

6ORZ5HVSRQVH VHFRQGV

0RXQW7HUPLQDWHDQG$XWR=HURWKHXQLW

DVGHVFULEHGLQODWHUVHFWLRQV$WWDFK

WKHGHDGKHDGWXELQJWRWKHSRUWVGXULQJ

$XWR=HURLQJ

www.ruskin.com • 3900 Dr. Greaves Rd. • Kansas City, MO 64030 • (816) 761-7476

INS ALLA ION AND OPERA ION INS RUC IONS

AMS SERIES RANSDUCERS (AMS8100, AMS8100LR)

SWI CH SE UP - OU PU S, RANGES, UNI S/RESPONSE

ALL STATED SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE OR OBLIGATION. © Ruskin October 2019

II-AMS8100-1019/Replaces -AMS8100-619

Figure 1

Do not have power applied to unit when changing settings. After changing settings, apply power and Auto-Zero the unit in its

orientation of operation.

Ruskin’s AMS series are the most versatile pressure

transducers on the market with selectable

pressure ranges and selectable voltage or current

output to satisfy the most demanding air measure-

ment applications. Switch selectable fast or slow

response time provides the ability to smooth out

velocity pressure measurements that are the result

of less than ideal installation locations and turbulent

air flows.

The LCD display shows the actual velocity pressure

independent of the output pressure range selected.

This makes it extremely easy for the installing tech-

nician to know what pressure range to use for each

application. With the maximum air flow passing

through the air measurement station just look at the

displayed value and select the lowest range that

includes the pressure. t’s that easy! By selecting

the correct pressure range, the electrical output can

be scaled for the greatest measurement resolution

and corresponding air flow control.

At a glance troubleshooting can save hours of work.

The three LEDS on the face of the AMS series

low-pressure transducer, above the display, indi-

cate when the velocity pressure being measured is

“Out of Range Low” (or negative), “Out of Range

High” or operating as expected when the “ n

Range” LED is illuminated.

PRODUC IDEN IFICA ION

AMS Series Transducer with Display

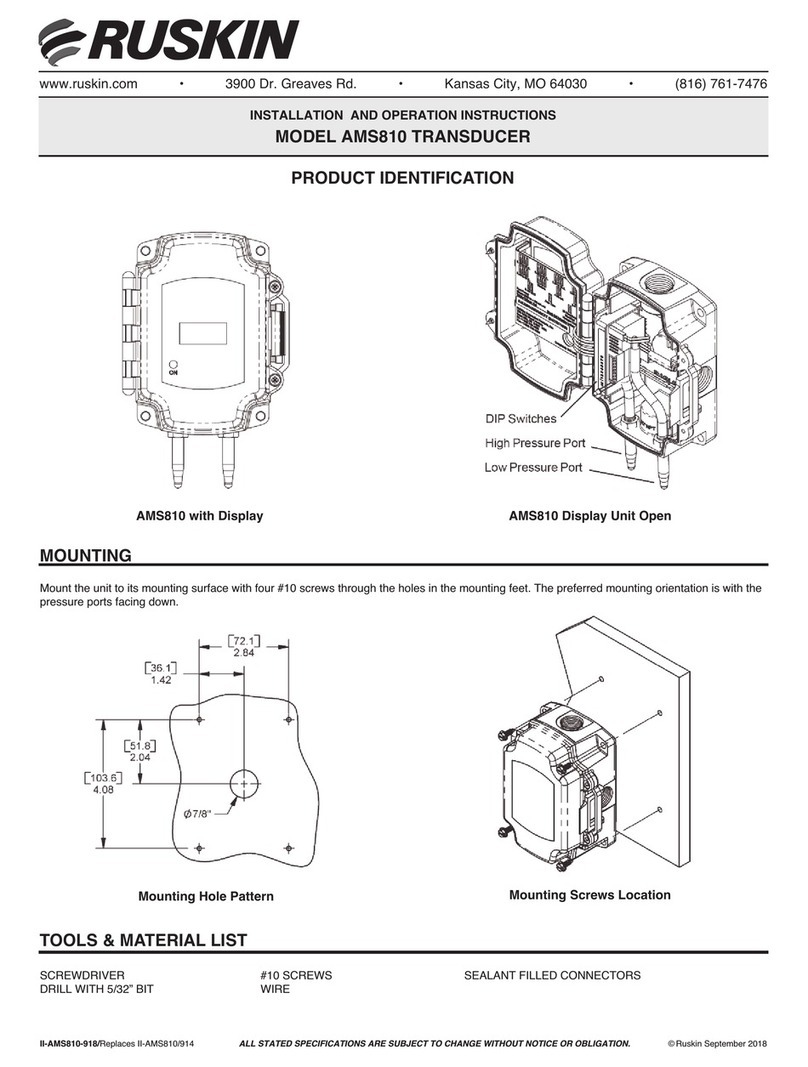

1. Select OUTPUT

2. Select RANGE

f unit is ordered with a Custom Range,

then the switch must be set to R6.

3. Choose D RECT ON

Bidirectional is a plus/minus range so

choosing 5” range is -5” to +5” Bidirectional

and 0” to +5” Unidirectional

4. Choose UN TS - nches WC or PASCALS

5. Choose RESPONSE T ME

Fast Response = 1/2 second

Slow Response = 4 seconds

6. Mount, Terminate and Auto-Zero the unit

as described in later sections. Attach

the deadhead tubing to the ports during

Auto-Zeroing

Field Selectable Ranges (inches water column)

Model AMS8100LR: 0-0.1", 0-0.25", 0-0.50", 0-0.75", 0.1.0"

Model AMS8100: 0-0.1", 0-0.25", 0-0.50", 0-1.0", 0-2.5"