MANUAL 2010 March

6

--GENERAL INSPECTION & MAINTENANCE—

Daily visual inspection shall be conducted of the structural components and other critical components, such as pin, bolts and locking

devises (including pawls). Check for metal/weld fatigue on all parts including slide mechanism on platforms. Check for bent or worn

parts or components that need maintenance, repair or replacement. When parts or components need replacement, they shall be

identical or equivalent to original parts or components.

Environmental conditions such as acidic rain, salt water air or extremely wet conditions can have an impact on various equipment

parts and must be taken into account when determining if inspections should be made more frequently than the recommended

minimums. Amount of use and amount of towing should also be taken under considerations to determine if inspections should be

made more frequently than the recommended minimums.

The following are minimum frequency recommendations regarding the inspection and maintenance of the unit:

KEY: D-Daily W-Weekly M-Monthly

D 1. Check to be sure Instruction Manual is in Instruction Manual storage holder

D 2. ALL decals are in place and legible

D 3. Check brake handles, they should move easily. Oil or grease pivot.

D 4. Lock brakes. If wheels turn easily, re-adjust brake adjusting bolt on brake band until wheel is securely locked. If

wheels still turn, brake band linings are probably damaged-replace.

D 5. Check tire pressure & wear. Maintain maximum recommended tire pressure. Replace worn out tires. Tires

should be matched sets on each axle. Check lug nuts for tightness.

D 6. Front & Rear tongue bolts tight.

D 7. Is Rear steering tongue working properly. CHECK BEFORE TOWING ON STREETS & ROADS.

D 8. Check Extension Ladder safety catch; it should move freely.

D 9. Ladders should not have bent or broken rungs.

D 10. Check winch cables. If frayed or badly pinched, replace. Make sure Hair pin clips are in place.

D 11. All guardrails are straight, in place, and secured with ¼” safety pins.

D 12. Entry latches are in working order.

D 13. All x-brace are straight. Check for excessive wear or metal cracks at connections and/or brackets.

W 14. Inspect cable sheaves & clevis pins for wear. Lubricate with heavy oil or grease

W 15. Check lift arm ropes for wear and/or deteriorations, replace as needed.

W 16. If uprights or extensions have been bent or severely twisted-replace.

W 17. Grease inside lip of uprights to prevent lift arms from binding or dragging.

W 18. Grease adjusting arm threads, two zirks per arm. Oil ball joints located on each end of arms.

W 19. Grease platform slide brackets and inspect for cracks and/or metal fatigue.

W 20. All toe boards are in place and in good conditions.

W 21. Inspect decking for holes, soft spots or any other deterioration.

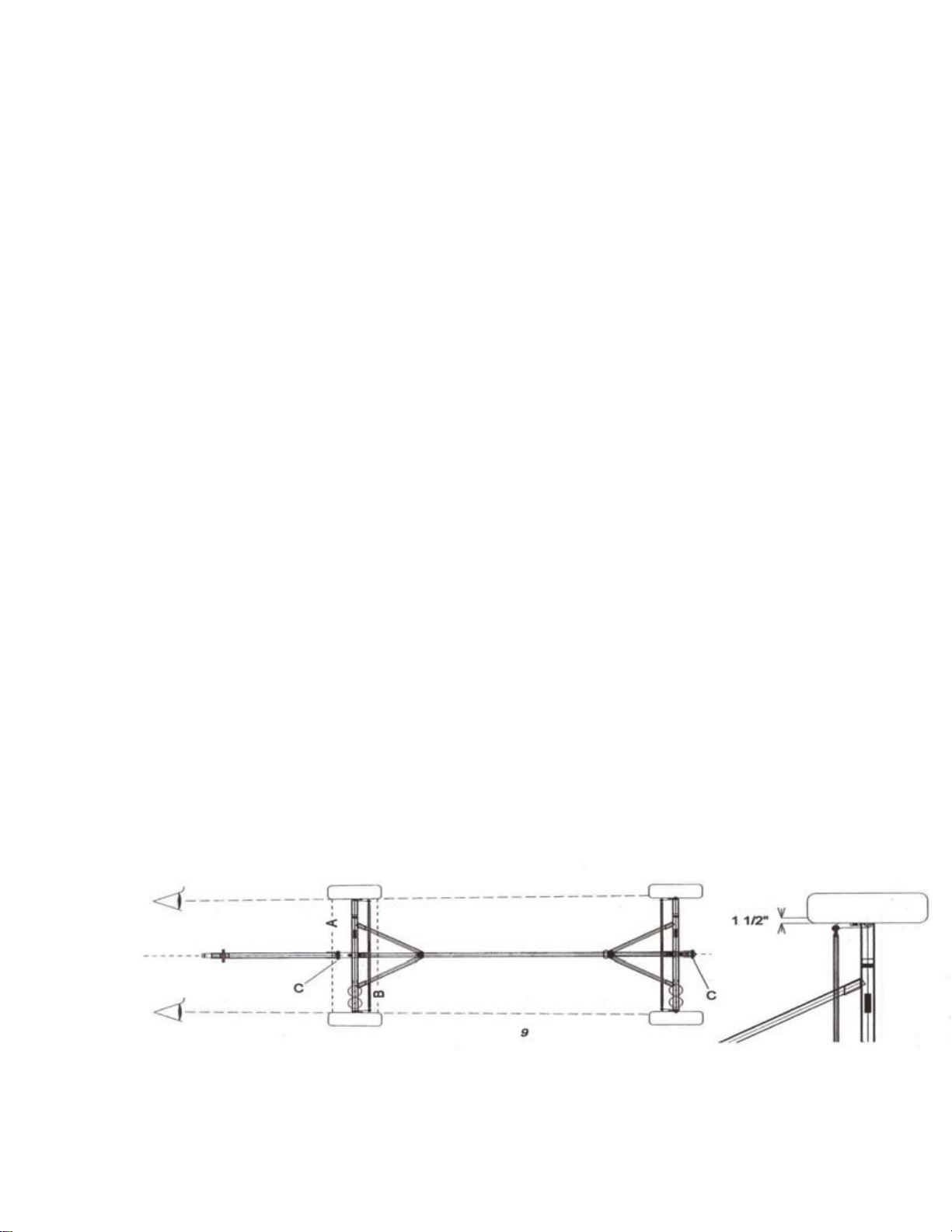

M 22. Grease front & rear axles, three zirks per axle.

M 23. Check the wheel alignment for proper tow.

M 24. Grease wheel bearings and check for play. Should be repacked at a minimum-annually.

M 25. Inspect reach pipe bolts & square washers for wear.

M 26. Reach pipe is straight, not bent. CHECK BEFORE TOWING ON STREETS & ROADS.

M 27. Check spherical tierod ends for wear.

M 28. Inspect the lift arm pawls & springs for wear & tension.

M 29. Inspect all bolts for wear. Replace or tighten as needed.