INSTALLATION AND SETUP

RUSTIBUS® 400 AIR

Before you begin.

Step 1: VERIFY THE COMPLETENESS OF YOUR RUSTIBUS® MACHINE.

• Check that all components are attached properly and in a proper / safe working order.

(Check that there are no loose wires, guards or parts on the machine)

Step 2: ASSOCIATED EQUIPMENT.

• Ensure that you have available required Air Pressure & volume.

(2,4 m³/min (85 CFM ) / 7-8 Bar (101-116psi))

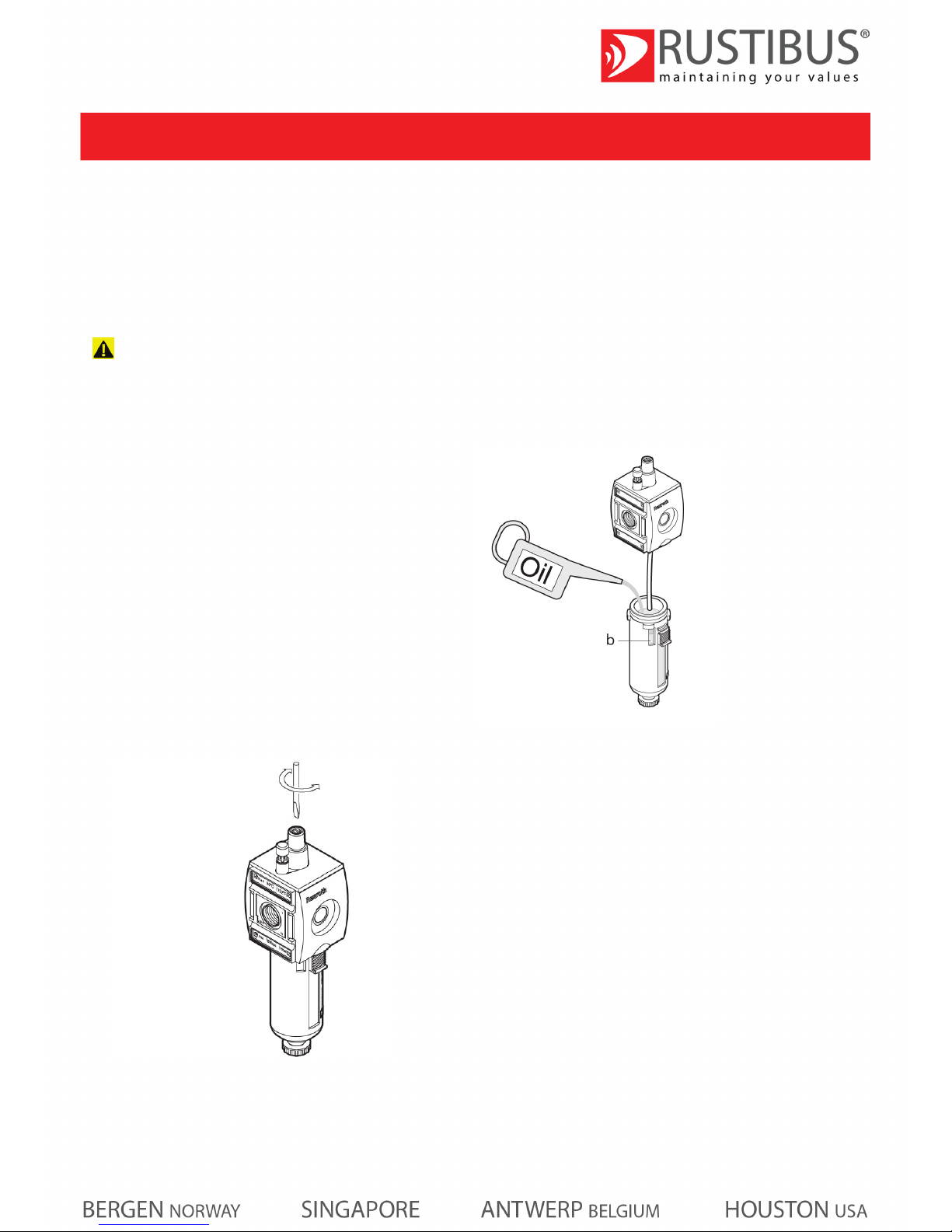

• Ensure that you have available Air tool oil to ll the Lubricator to the required level.

Step 3: BEFORE COMMENCING THE OPERATION.

•Locate the section to be cleaned / de-scaled and determine if the area needs to be cleaned. Excessive

grease, dirt and other hazardous material should be cleaned from the surface area before

operation of the Rustibus® machine.

• Conrm the correct air pressure before connecting hose supply.

• Check oil level container and ll with air tool oil as required (Only ll to 75%)

• The Chain drum is rotating at high RPM, show outmost care when connecting Air hose and when

operating machine. ALWAYS THINK SAFETY FIRST!

• Connect your machine to its power source.

• Make sure the air hose is properly connected and safely located for your operation. Apply safety wire

on hose.

• ALWAYS lift up machine (push down the handle) in order for the chain drum to rotate freely when

starting the machine.

• Start and Stop the machine and check that rotation is correct according to marking on machine.

Step 4: OPERATION OF RUSTIBUS® MACHINE.

• For the best results from your Rustibus® machine you should run the machine forward and backward

over the area until appropriate result is achieved

• Do not run the machine over sharp edges, but along them. Your machine will last longer if operated

with care.

Step 5: MAINTENANCE OF RUSTIBUS® MACHINE.

• ALWAYS stop the machine and disconnect it from its air power source before carrying out any

maintenance on the machine.

• Use the Disposable Chain Drum until it is completely destroyed and then replace the entire drum with

a new one.

• When the machine is stowed away after use, it should be lled with 0,1 litre (3.38 US oz) of

lube oil to ensure functionality upon next time of use. Fill the oil into the T-pipe (040-4021) by

removing the cap (040-4029). Gently rotate the chain head 2-3 times to make sure the oil lubricates

the air motor.

Genuine Rustibus® parts only! Machine may vary from pictures