1MOBILE AND WORKSHOP SERIES OPERATION MANUALOctober 2018 | Version: v1-0

CONTENTS

GENERAL...................................................................................................................................................................2-6

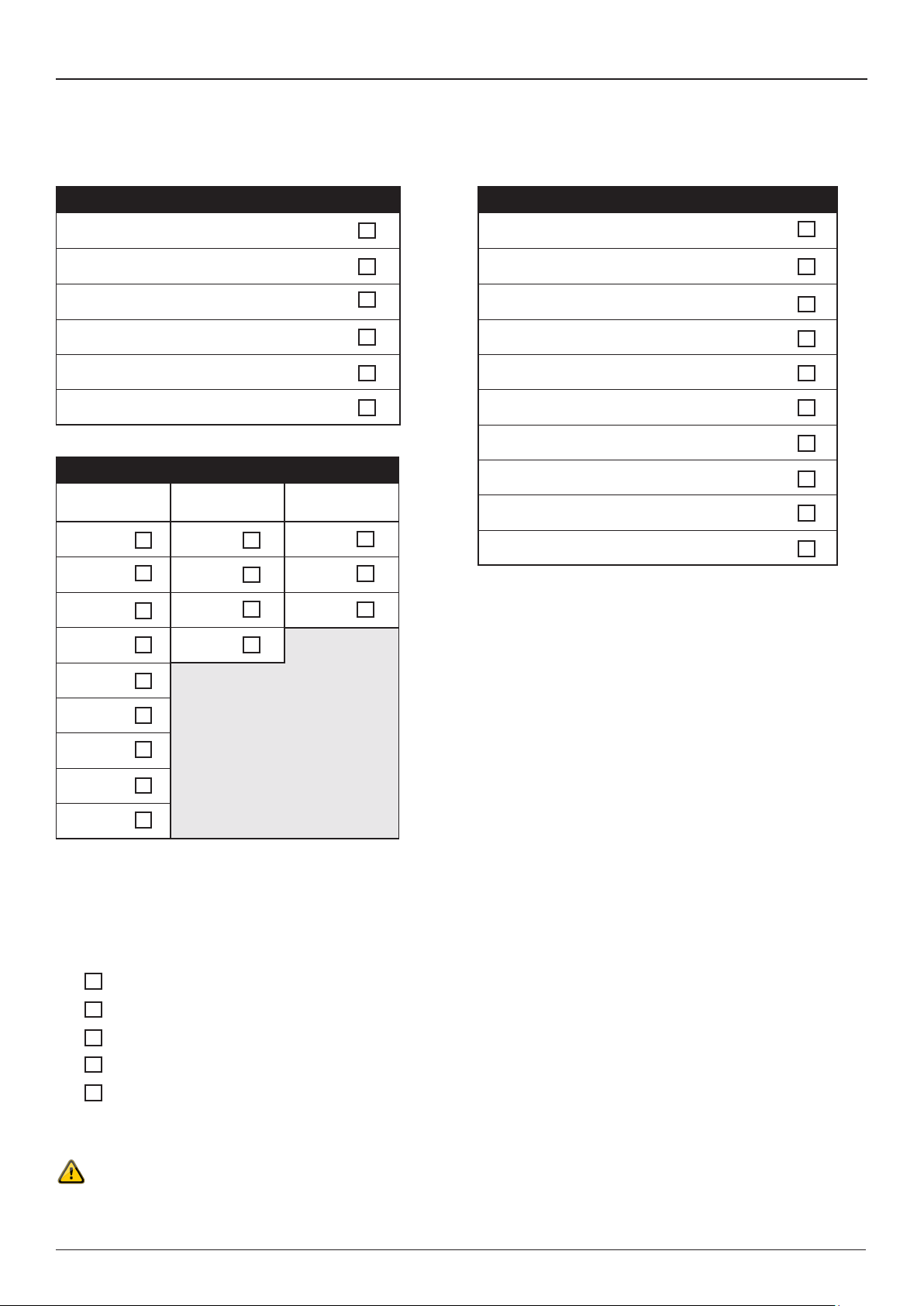

HECKLIST............................................................................................................................................................................................................. 3

Pre-Delivery Checklist............................................................................................................................................................................................ 3

Pre-Commencement Inspection ............................................................................................................................................................................. 3

SAFETY............................................................................................................................................................................................................. 4-11

Restriction ............................................................................................................................................................................................................. 4

Danger Zones ........................................................................................................................................................................................................ 5

Safety Notes .......................................................................................................................................................................................................... 5

Hose Assembly...................................................................................................................................................................................................... 5

Machine Installation ............................................................................................................................................................................................... 5

Safety Instruction................................................................................................................................................................................................... 6

Battery and Oil....................................................................................................................................................................................................... 7

Oil Fill.................................................................................................................................................................................................................... 7

Running-In............................................................................................................................................................................................................. 7

Greasing................................................................................................................................................................................................................ 7

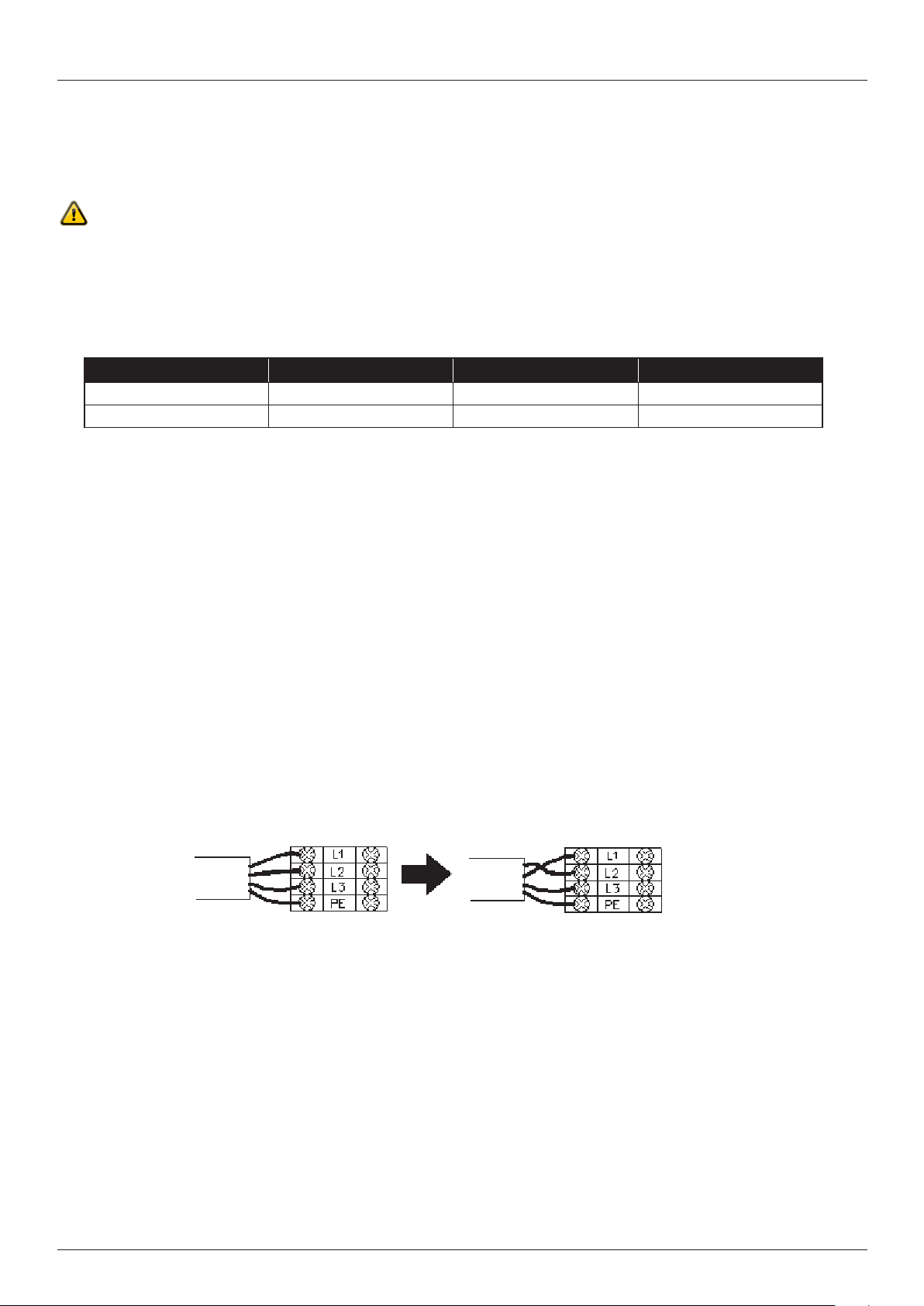

Installation of Power Supply................................................................................................................................................................................... 8

Transporting .......................................................................................................................................................................................................... 9

Base Mounting....................................................................................................................................................................................................... 9

Danger Zones and Warning Labels ..................................................................................................................................................................10-11

OPERATION............................................................................................................................................................12-17

START UP..............................................................................................................................................................................................................12

Hydraulic System..................................................................................................................................................................................................12

Functional Tests and Re-Testing...........................................................................................................................................................................12

SELECTING THE DIE SETS ......................................................................................................................................................................................13

RY20 Die Sets ......................................................................................................................................................................................................13

RY32 Die Sets ......................................................................................................................................................................................................13

MOBILE AND WORKSHOP SERIES ...........................................................................................................................................................................14

Start Up ................................................................................................................................................................................................................14

Operation..............................................................................................................................................................................................................14

Installing The Die Set............................................................................................................................................................................................14

QUICK CHANGE TOOL.............................................................................................................................................................................................15

Quick Change Tool ...............................................................................................................................................................................................15

Change of a Single Die Set ..................................................................................................................................................................................15

CONTROL IDENTIFICATION.....................................................................................................................................................................................16

Digital Control Panel .............................................................................................................................................................................................16

Crimping ..............................................................................................................................................................................................................17

SPECIFICATIONS ....................................................................................................................................................18-22

RY20C..................................................................................................................................................................................................................18

RY32C..................................................................................................................................................................................................................19

RY20CB ...............................................................................................................................................................................................................20

RY32CB ...............................................................................................................................................................................................................21

RY32CB ...............................................................................................................................................................................................................21

Calibration ............................................................................................................................................................................................................22

MAINTENANCE.......................................................................................................................................................23-24

HOW TO MAINTAIN YOUR CRIMPER.........................................................................................................................................................................23

Cleaning ...............................................................................................................................................................................................................23

Lubrication/Greasing.............................................................................................................................................................................................23

Oil Change ...........................................................................................................................................................................................................23

Master Spring Change ..........................................................................................................................................................................................23

Pressure Pipes .....................................................................................................................................................................................................23

Troubleshooting ....................................................................................................................................................................................................24

TECHNICAL ............................................................................................................................................................25-34

ELECTRICAL SCHEME ............................................................................................................................................................................................25

Electrical Components List - RY20CB/RY32CB .....................................................................................................................................................26

Electrical Components List - RY20C/RY32C..........................................................................................................................................................27

ASSEMBLY ............................................................................................................................................................................................................28

Assembly of RY20/RY32.......................................................................................................................................................................................28

Assembly of RY20CB/RY32CB .............................................................................................................................................................................29

Assembly of RY20C/RY32C ..................................................................................................................................................................................30

Master Die Misalignment Troubleshooting ........................................................................................................................................................31-34