3OPERATION

3.1 Operation Guidelines

•The AirBoss system was pre-tested for leaks before shipping, however, we recommend that you test

the system using WATER to ensure you do not have leaks before moving onto sealant

•The air-pump is self-priming

•Flush clean water through the pump and hoses at the end of each day

•Place any used spray tips into a soapy water solution at the end of each day

•Do not let sealant dry onto the spray tips

•Clean the spray tips with soft nylon brushes only

•Have clean water available at the job site for emergency rinsing

•Clean the strainer daily to ensure proper sealant flow

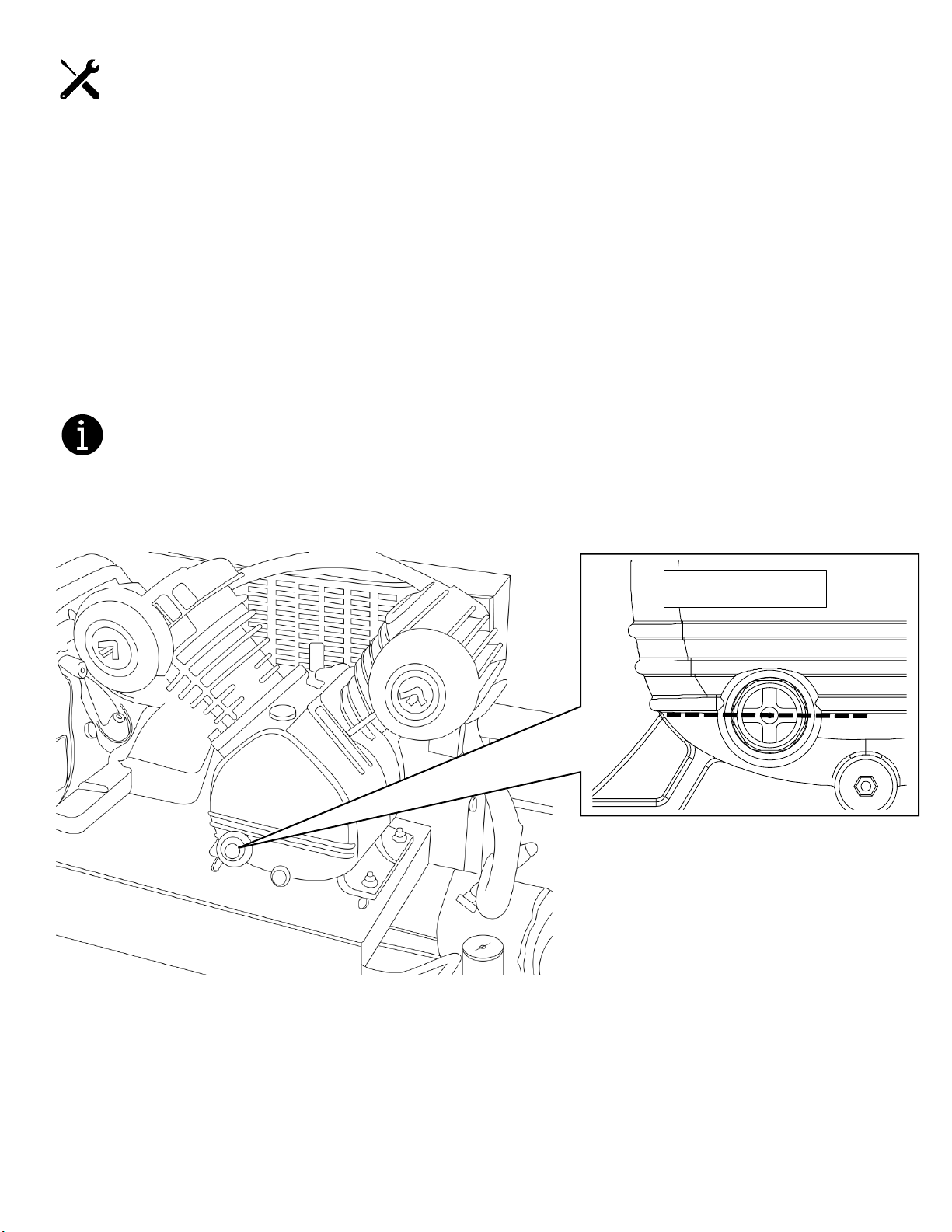

•Check the engine oil levels daily

•Check the compressor oil levels daily

•Check the hydraulic oil levels daily *if equipped

•Check the airline oiler oil levels daily *if equipped

⚠WARNING

●Turn the engine off for extended work stoppages (10+ minutes), such as breaks, lunches, or other unplanned

work stoppages

●avoid recirculating for more than 10 minutes at a time

NOTE: Apart from wasting fuel, this may cause your sealant to become foamy, which can introduce excessive

air into the lines and can cause inconsistent spray intensity.

●Foamy sealant can take an hour or more to return to a useable state.

●Set fuel control to OFF while traveling (if equipped)

Spray Tips

Each system ships with 4 sizes of spray tips (80/30, 80/40, 80/50, 80/70). The spray wand (RA-SWA-0005)

included with your AirBoss will have an 80/20 tip installed on it for a total of FIVE tips.

The 80/20 tip is what all our benchmarks were completed with (see the specifications chart for details). The 2

numbers are used to designate the spray tip size denote the spray fan angle and tip flow when sprayed at 40

psi (for example, an 80/20 has an 80° spray fan angle and has approximately 2.0 GPM of flow when sprayed at

40 psi). Increasing or decreasing the regulator pressure will also increase or decrease the tip flow rate from

the 40 psi rating.

Tip sizes like an 80/20 or 80/30 are ideal for smaller jobs, like driveways, while larger tips are more suitable for

large driveways and parking lots. You will also need to consider the type of product you are working with.

Coal tar products have less solids in them and should work trouble free with any of the included sizes.

Emulsion based sealers have more solids in them, and will likely require 80/50 tips or larger to work effectively.