Ryobi RY48ZTR75 User manual

Other Ryobi Lawn Mower manuals

Ryobi

Ryobi OLM1833B User manual

Ryobi

Ryobi RLM16E36H User manual

Ryobi

Ryobi RY18SFX35A User manual

Ryobi

Ryobi RLM3640Li User manual

Ryobi

Ryobi RY48ZTR100 User manual

Ryobi

Ryobi RM-1600 Operation manual

Ryobi

Ryobi RLM36BL User manual

Ryobi

Ryobi R18XLMW54 User manual

Ryobi

Ryobi RLM3715 User manual

Ryobi

Ryobi RY401017 User manual

Ryobi

Ryobi RLM18X41H240 User manual

Ryobi

Ryobi RLM53175S User manual

Ryobi

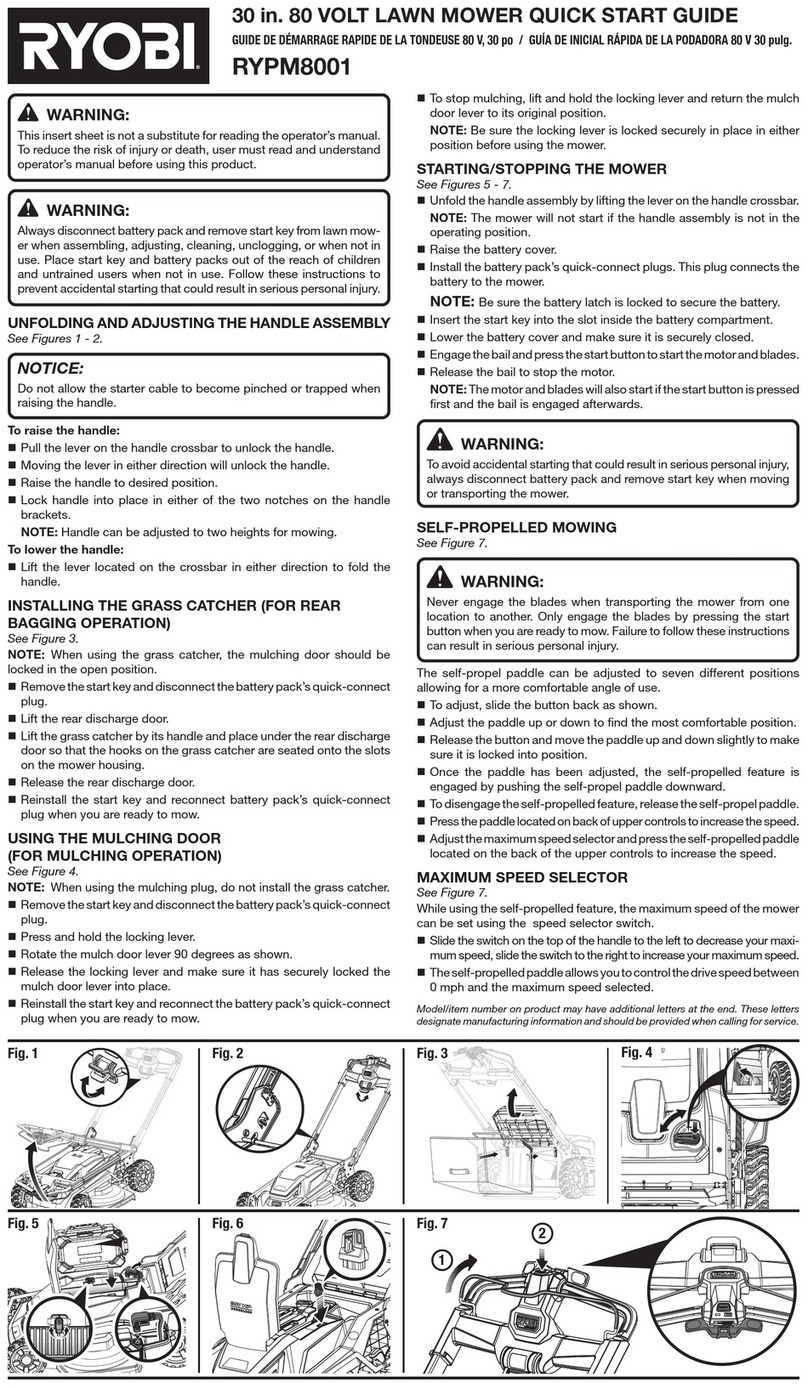

Ryobi RYPM8001 User manual

Ryobi

Ryobi RLM36X40H User manual

Ryobi

Ryobi RLM13E33S User manual

Ryobi

Ryobi RYPM8001 User manual

Ryobi

Ryobi RLM46140 User manual

Ryobi

Ryobi RY1400SF35B User manual

Ryobi

Ryobi RLM53190SV User manual

Ryobi

Ryobi RLM4617SME User manual

Popular Lawn Mower manuals by other brands

TALEN TOOLS

TALEN TOOLS AVR HGM30 manual

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual