2

SPECIFIC SAFETY WARNINGS

3

■Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body leaves it unstable and may lead to

loss of control.

■Hold power tools by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will also make exposed metal parts of the

tool “live” and shock the operator.

■Know your power tool. Read operator’s

manual carefully. Learn its applications and

limitations, as well as the specific potential

hazards related to this power tool. Following

this rule will reduce the risk of electric shock, fire

or serious injury.

■Always wear safety glasses with side

shields. Everyday glasses have only impact

resistant lenses. They are NOT safety glasses.

Following this rule will reduce the risk of eye

injury.

■Protect your lungs. Wear a face or dust mask

if the operation is dusty.

■Protect your hearing. Wear hearing

protection during extended periods of

operation.

■If using an extension lead, ensure that the

male and female plug connection is elevated

and out of the way of any water contact.

It is recommended that the tool always be supplied

via a residual current device with a rated residual

current of 30mA or less.

FITTING THE SANDPAPER

■Ensure the sandpaper is taut on the base with

the edges and dust collection holes evenly

aligned (Fig. 2).

■Do not make any adjustment while the motor is

in motion.

■Always disconnect the electrical cord from the

power source before changing the sandpaper,

brushes, or when working on the unit.

■After use, check your tool to keep it in top

condition.

■Clean out accumulated dust.

■When the carbon brushes are worn to the

standard line, they must be replaced.

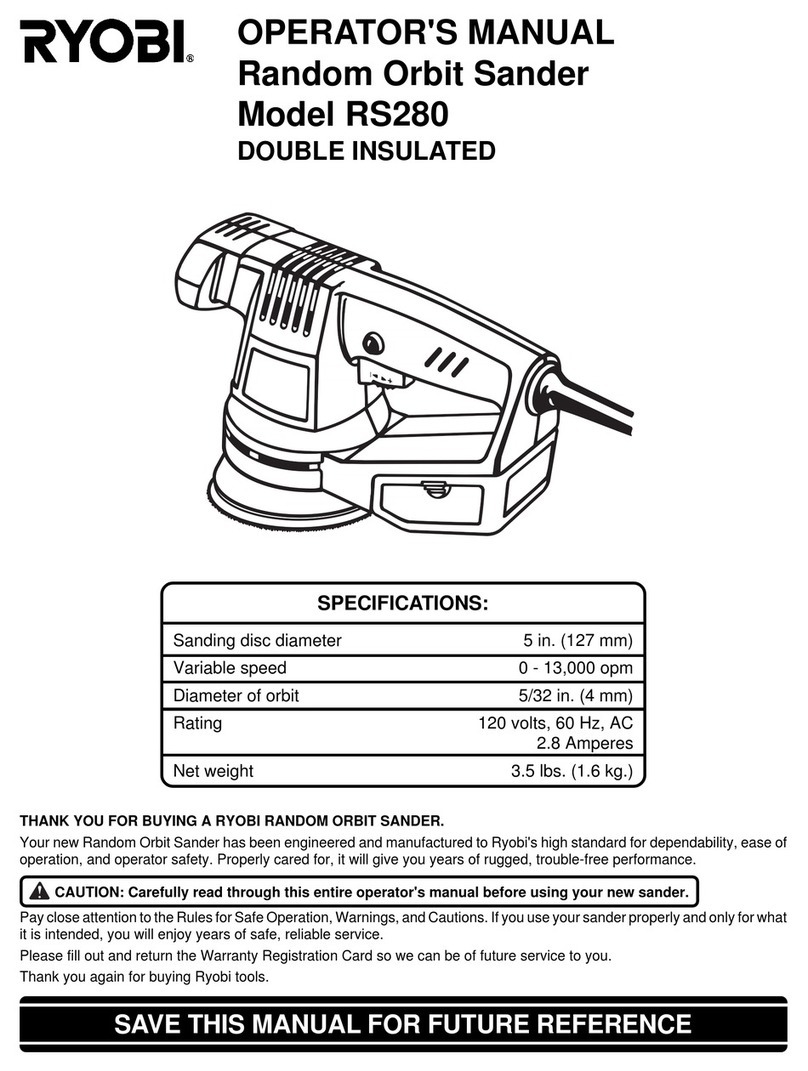

SPECIFICATIONS

Power input:

No load speed:

Sanding pad size:

Net weight:

200 W

5,000-10,000 min-1

90 x 184 mm

1.75 kg

OPERATION

OPERATION

MAINTENANCE

Now that you have purchased your tool, should a

need ever exist for repair parts or service, simply

contact your nearest Ryobi Authorised Service

Centre or other qualified service organisation. Be

sure to provide all pertinent facts when you call or

visit.

SERVICE

■Pull out both the front and rear clamping levers

to the open position and insert the ends of the

sandpaper under both clamps. (Fig.3)

■Ensure that the sandpaper is taut on the base.

■Push both clamps in to the closed position to

secure the sandpaper. (Fig.4)

VARIABLE SPEED CONTROL (Fig.5)

The variable speed control wheel is used to

programme the required sanding speed. In this way

the speed can be adapted to match the material

being worked.

■Turn the wheel to the right to increase the speed.

■Turn the wheel to the left to decrease the speed.

SANDING

■Your sander starts and stops by depressing and

releasing the trigger switch. (Fig.6)

WARNING:

Never cover the air vents. They must be

open at all times for proper motor cooling.

WARNING:

Always remove the electric cord from the

power supply when changing sanding paper,

polishing pad or when working on the tool.

WARNING:

This sander is designed for light consumer

use. It is NOT designed for trade or industrial

use and is not covered by the guarantee for

use in these applications.

WARNING:

Make sure the workpiece is free of nails and

foreign objects which could tear the sanding

paper.

■For continuous operation, press the lock-on

switch while the trigger is depressed. Depress

the trigger switch to release the lock (Fig.7).

■Move the sander evenly over the entire work

area. (Fig.8) The weight of the sander alone is

sufficient for normal use. Any excess pressure

will retard the sanding action, giving an uneven

finish and cause extra wear to both tool and

sanding paper.

■Never allow sander to stay in one place too

long, or excessive material will be removed.

Always start sander before applying it to the

work piece.

■The sander should never be turned off while

resting on the work piece. Lift the tool from

workpiece and then turn it off. Do not use the

tool without sanding paper, or the rubber pad will

be damaged. Take care that your hand does not

cover the vents and make sure oil or water does

not come into contact with the motor.

DUST COLLECTION BOX

■Your sander is equipped with a dust collection

box. To attach, insert the box into the back of the

sander. (Fig.9)

■To empty the dust box, remove the box from the

sander.

d) Store idle power tools out of the reach of

children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment of binding or moving parts,

breakage of parts and any other condition

that may affect the power tools’ operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool

bits etc., in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

GENERAL POWER TOOL SAFETY WARNINGS