1

English

GENERAL SAFETY RULES

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capa-

bilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use

of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not

play with the appliance.

WARNING

Read all instructions. Failure to follow all instructions

listed below may result in electric shock, fire and/or

serious injury. The term “power tool’’ in all of the

warnings listed below refers to your mains operated

(corded) power tool or battery operated (cordless)

power tool.

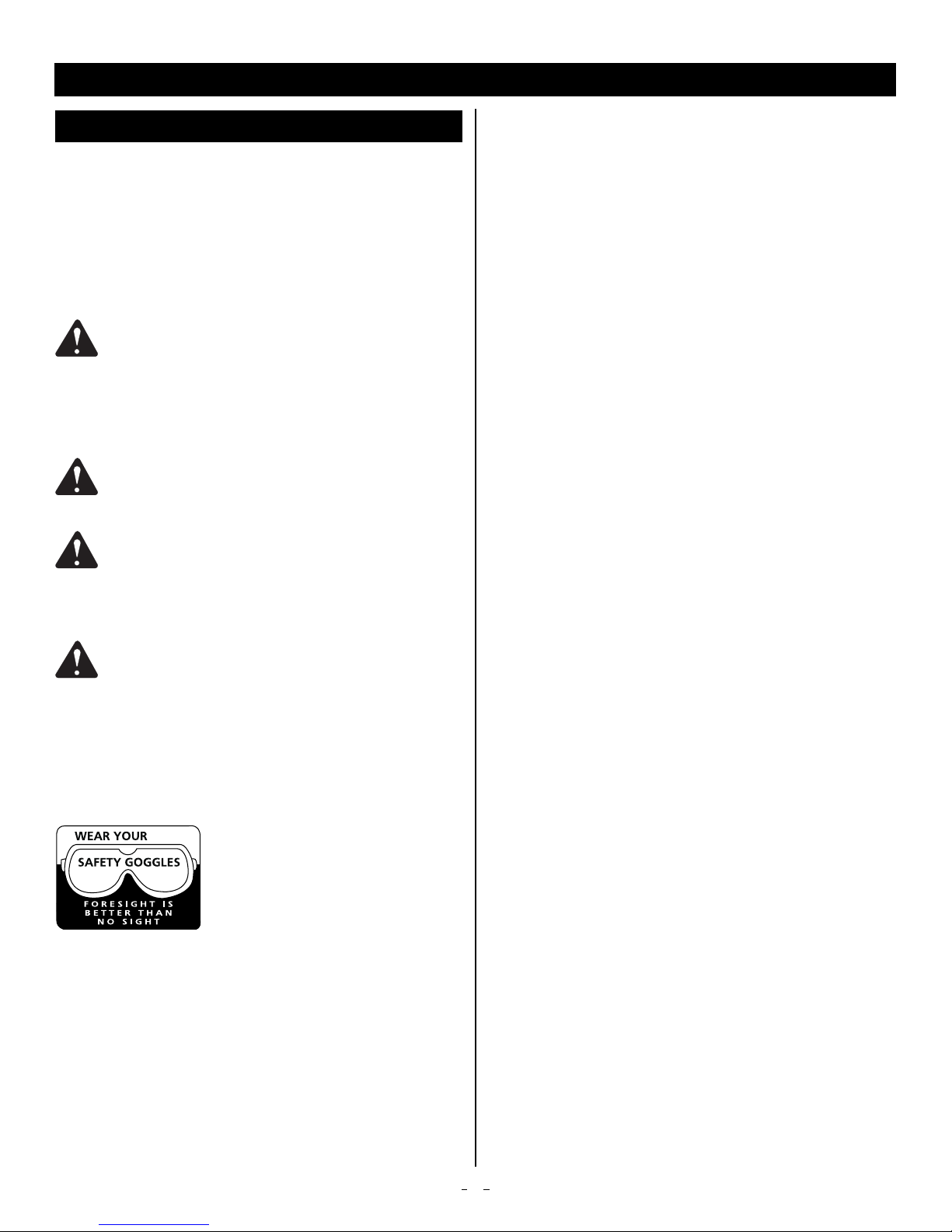

SAFETY ALERT SYMBOL. Indicates caution or

warning. May be used in conjunction with other

symbols or pictures.

WARNING

Failure to obey a safety warning can result in seri-

ous injury to yourself or to others. Always follow the

safety precautions to reduce the risk of fire, electric

shock and personal injury.

WARNING

Do not attempt to operate this tool until you have

read thoroughly and understood completely safety

rules, etc. contained in this manual. Failure to com-

ply can result in accidents involving fire, electric

shock or serious personal injury. Save owners

manual and review frequently for continuing safe

operation and instructing others who may use this

tool.

The operation of any tool can result

in foreign objects being thrown into

your eyes, which can result in severe

eye damage. Before beginning

power tool operation, always wear

safety goggles or safety glasses with

side shields and a full face shield when needed. We recom-

mend Wide Vision Safety Mask for use over eyeglasses or

standard safety glasses with side shields.

WORK AREA

nKeep work area clean and well lit. Cluttered or dark

areas invite accidents.

nDo not operate power tools in explosive atmos-

pheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

nKeep children and bystanders away while operat-

ing a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

nPower tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric

shock.

nAvoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

nDo not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the

risk of electric shock.

nDo not abuse the cord. Never use the cord for car-

rying, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts. Dam-

aged or entangled cords increase the risk of electric

shock.

nWhen operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric

shock.

nIf operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock.

PERSONAL SAFETY

nStay alert, watch what you are doing and use com-

mon sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication.A moment

of inattention while operating power tools may result in

serious personal injury.

nUse personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

nPrevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or plugging in power tools that have the switch

on invites accidents.

nRemove any adjusting key or wrench before

turning the power tool on. A wrench or a key left at-

tached to a rotating part of the power tool may result

in personal injury.