TECHNICAL MANUAL 620057E03

Due to the continuous products improvement, the indications of the present manual can be modified without previous warning and in any case are a

contract commitment. The present information publishing does not represent resignation of intellectual property or patent.

Copyright ©2009-2010 S.A. Sistel -E 08211 BARCELONA Pag. 3

0. Before you begin ............................................................................................................5

1. Safety...............................................................................................................................5

1.1 Precautions against damage to people......................................................................5

1.2 Precautions against damage to the product ..............................................................6

1.3 Limits of the guarantee..............................................................................................6

2. Certifications...................................................................................................................7

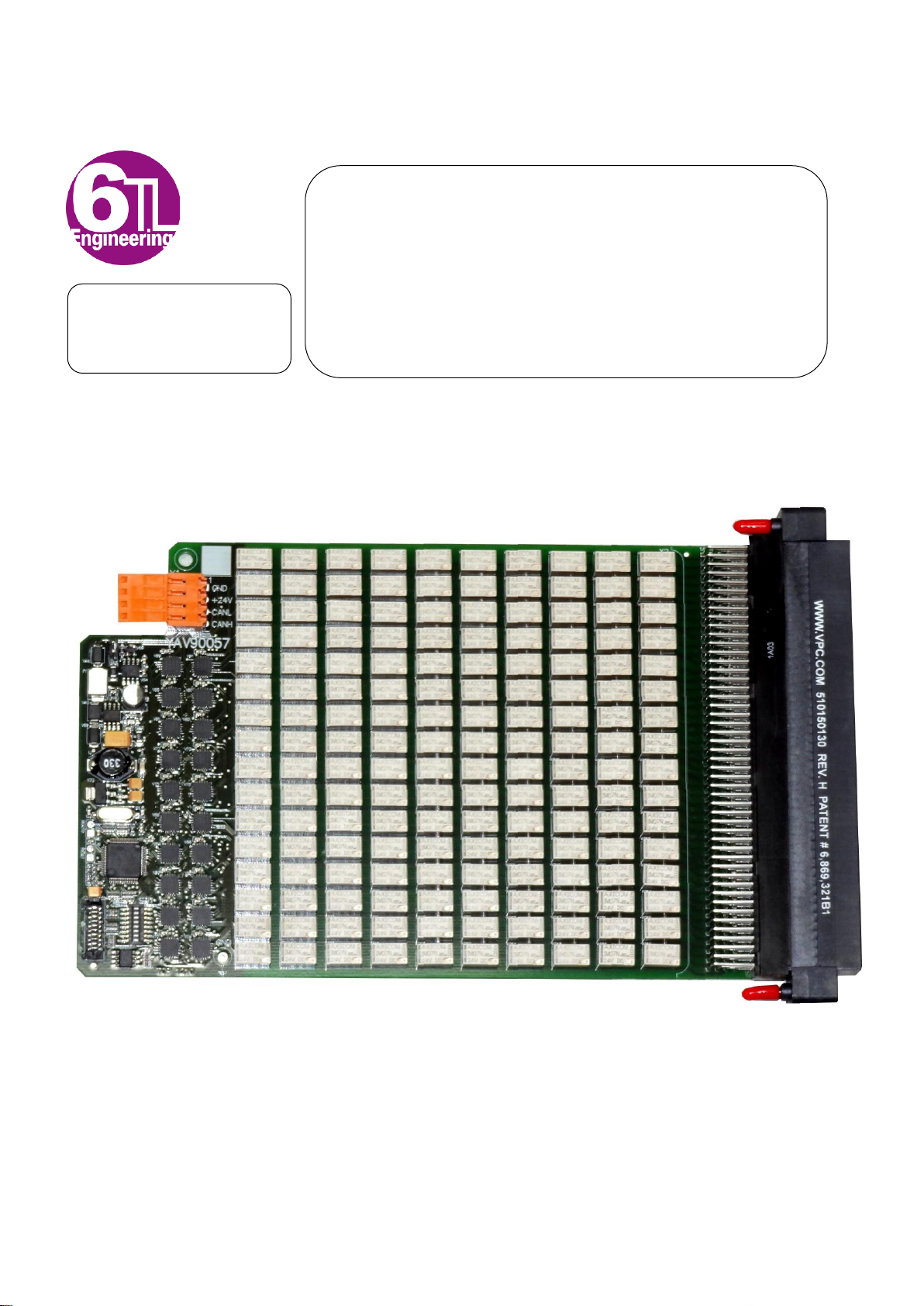

3. Description and main features ......................................................................................8

3.1General features........................................................................................................8

3.2 Applications ...............................................................................................................8

3.3 Ordering information..................................................................................................8

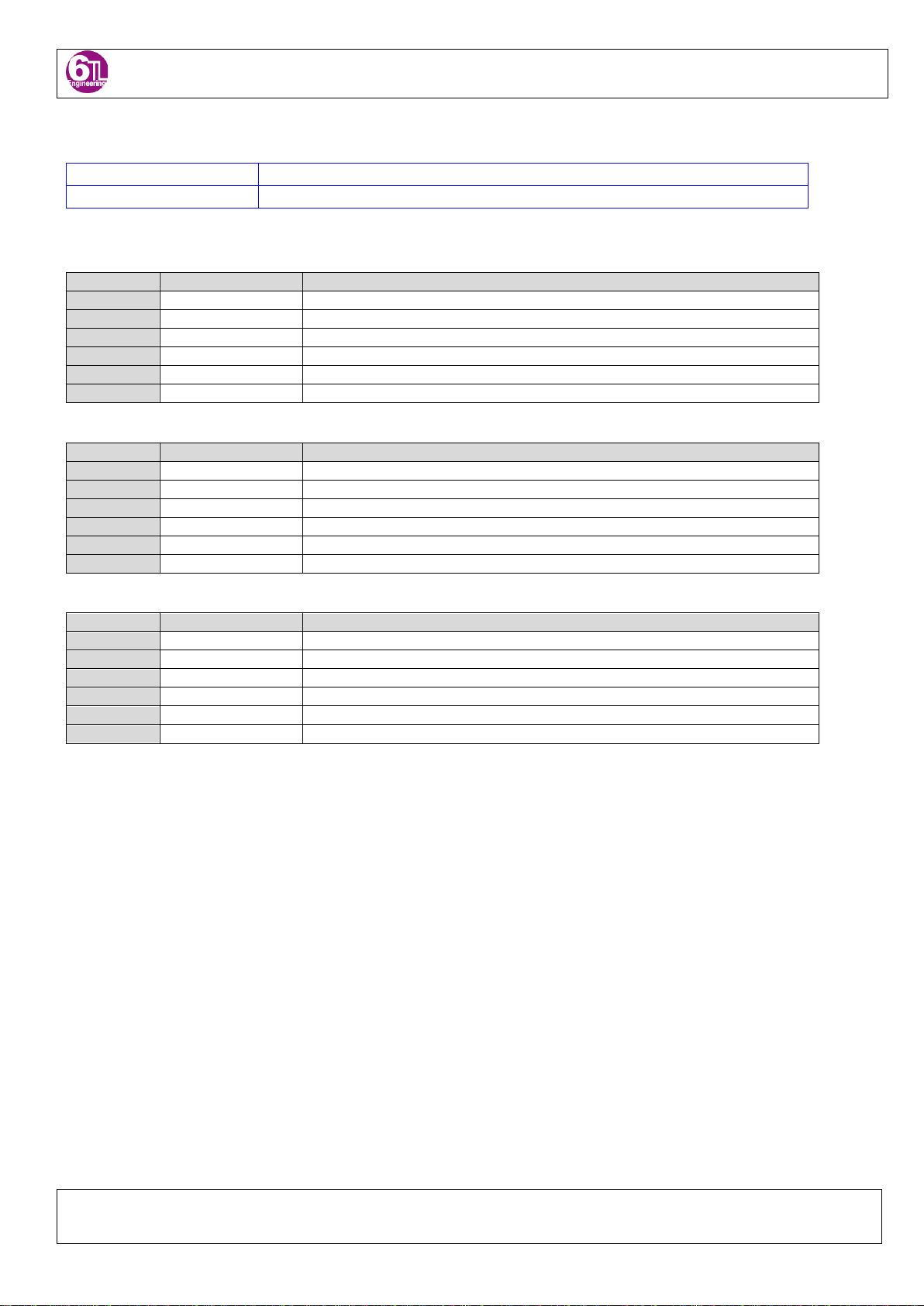

3.4 Device electrical Characteristics................................................................................9

3.5 Electric Diagram ........................................................................................................9

3.5.1 Connector X2.................................................................................................... 10

4. YAV modules common information............................................................................11

4.1 SW1 DIP switch functionality...................................................................................11

4.1.1 CAN bus communication speed. ...................................................................... 11

4.1.2 YAV module address........................................................................................ 11

4.2 YAV modules standard addressing & Virginia Panel Receivers ..............................12

4.1 Jumpers behavior....................................................................................................14

4.2 YAV boards Dimensions..........................................................................................15

5. Low level CAN commands...........................................................................................16

5.1 Example: Managing a YAV board using C language...............................................16

6. PHI6-Explorer panel......................................................................................................19

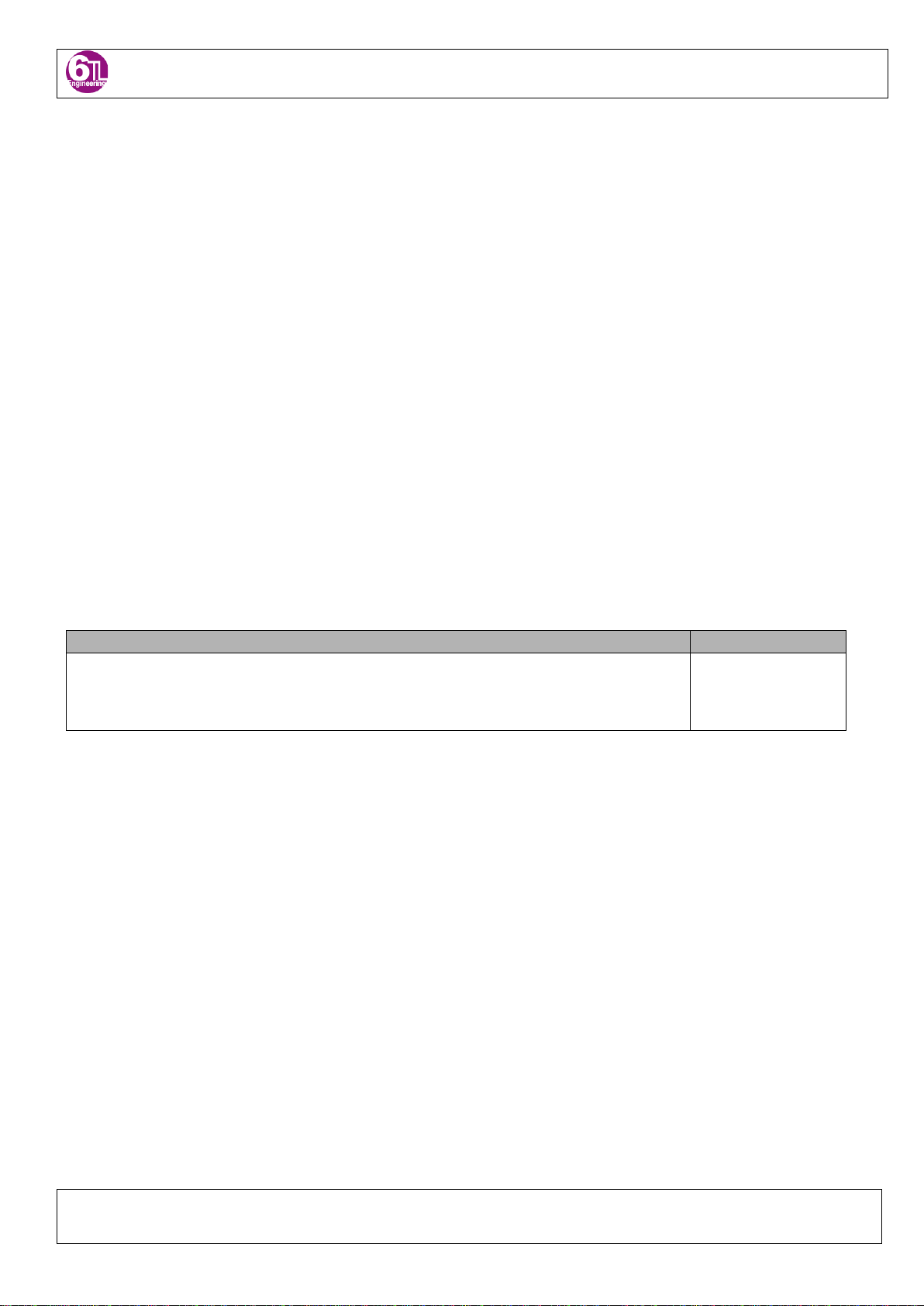

7. Install/Uninstall YAV boards into/from a VPC Receiver ............................................21

7.1 Modules in receiver side..........................................................................................21

7.1.1 Interfaces w/Quadrapaddle............................................................................... 22

7.2Connections.............................................................................................................23

7.2.1 Connecting cables into YAV board terminals.................................................... 23

8. Getting started with your YAV board..........................................................................24

8.1 NI CAN board ..........................................................................................................24

8.2 CAN bus wiring........................................................................................................24

8.3 PHI6-EXPLORER....................................................................................................24

9. YAV boards overview...................................................................................................25

10. Operation.......................................................................................................................25

10.1 Outputs Activation....................................................................................................25

10.2 Soft Panel................................................................................................................25