S Fire SF119 Series User manual

Photoelectric

Smoke Detector

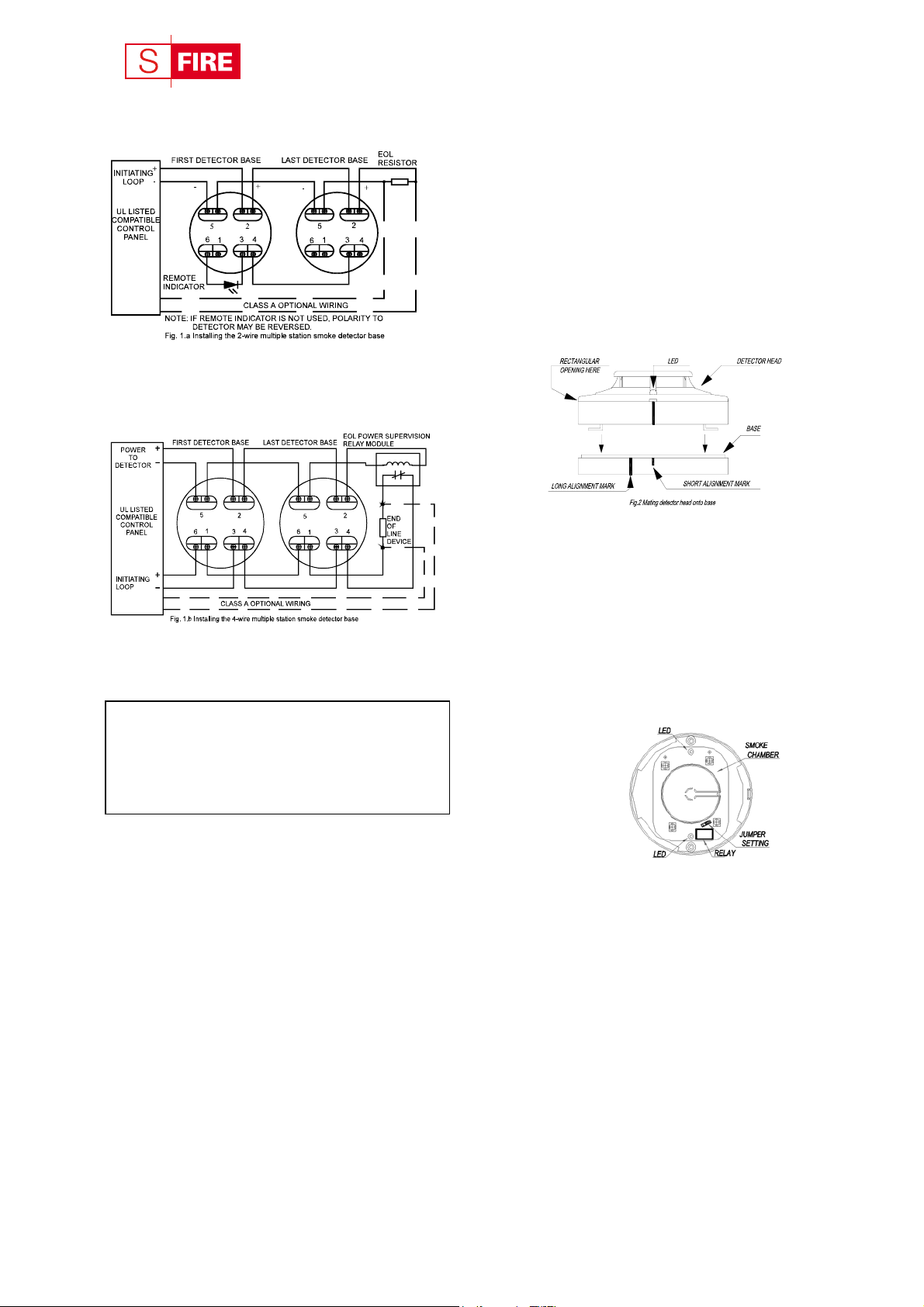

TYPICAL WIRING DIAGRAM

Figure 1.a shows the typical wiring diagram of 2-wire

multiple-station smoke detector system.

DO NOT USE LOOPED WIRE UNDER

TERMINALS 2 AND 5 BREAK WIRE RUN TO

PROVIDE SUPERVISION OF CONNECTIONS

Figure 1.b shows the typical wiring diagram of 4-wire

multiple-station smoke detector system.

DO NOT USE LOOPED WIRE UNDER

TERMINALS 2 AND 5 BREAK WIRE RUN TO

PROVIDE SUPERVISION OF CONNECTIONS

WARNING

TO PREVENT DETECTOR CONTAMINATION

AND SUBSEQUENT WARRANTY

CANCELLATION, THE SMOKE

DETECTOR MUST REMAIN COVERED

UNTIL AREA IS CLEAN AND DUST FREE.

INSTALLING THE BASE

1. To insure proper installation of the detector,head to

the base, all the wires should be properly

addressed at installation:

(A) Position all the wires flat against terminals.

(B) Fasten the wires away from connector terminals.

2. If you use the jumper wire to connect the poles of

terminal 2 and 5 when testing the detector

loop's continuity, be sure to remove the jumper wire

prior to the installation of the detector head.

3. The end-of-line device shown in Figure 1.a & 1.b

should be compatible with the control unit. The

end-of-line supervisory relay used should list the rated

DC power voltage used.

4. Per UL listing, open area smoke detectors are

SF119 series

Installation Wiring Diagram

intended for mounting on a ceiling at least 6 inches

away from a wall or mounting on a wall between 4 and

12 inches away from a ceiling.

5. The base of smoke detector can be mounted directly

onto an electrical junction box:octagonal (3”, 3.5” or

4”), round (3”), and square (4” length) boxes without

using any type of mechanical adapters.

INSTALLING THE HEAD

1. Align the components as shown in Figure 2.

2. Mate the detector head onto the base and twist it

clockwise to secure it.

3. Do not install the detector head until the area is

thoroughly cleaned of construction debris, dusts, etc.

The maximum number of smoke detector installed in

the same loop is 30 units.

Fig. 2 Mating detector head onto base

ADJUSTMENT OF THE RELAY POSITION

4-wire type: Adjust the relay set-position for wiring unit to the

security monitoring system through the following steps:

1. The reset position for the relays is “normally open”

(NO), when powering all the relays.

2.

3.

To adjust the relay set point, use a screwdriver to

loosen the two screws on the back of the base.

Figure 3 shows a jump head next to the relay on the

PCB, adjust it to select either the “normally

closed” (NC) or the “normally open” (NO) positions.

Relay contact rating:

1A @30VDC,

0.5A @125VAC.

TESTING

1. All the alarm signal services, releasing device and

extinguisher system should be disengaged during the

test period and must be re-engaged immediately at the

conclusion of testing.

2. After powering the detector head for approximately

one minute, check if the red LED light is flashing

once every 1~3 seconds. If the red LED fails to

flash, it indicates that the detector is not functioning

properly or the possibility of having incorrect wiring.

Re-check the wiring or replace the detectorif

necessary.

Fig. 3 Schematic ofdetectorstructure

When front cover is open

3. Allow smoke from a cotton wick or a punk to enter the

detector’s sensing chamber for at least 10 seconds.

When sufficient smoke has entered the chamber, an

alarm signal would be triggered by illuminating the

LED. After the alarm is triggered, reset each

detector and/or control unit before attempting to

test the additional detectors in the same zone. If the

alarm fails in this step, it indicates a defective unit,

which would require service.

HEAT SENSOR TESTING

To test the detector, it should be subject to a flow of

warm air at a temperature between 284F and 356F

(140C and 180.C). Some domestic hair dryers can meet

this requirement. Proceed as follows:

1. Switch on the warm airflow and check that the

temperature is correct and stable.

2.

3.

Direct the airflow at the guard protecting the

thermistor. The detector should be triggered within 30

seconds.

When the alarm is on, immediately remove the

heat source and check that the detector’s red LED

is on. Reset the detector from the control panel.

4. If the detector fails to trigger the alarm within 30

seconds,it would mean that it should be returned to the

distributor for servicing to adjust its sensitivity.

5. After testing,check that the system is set for

normal operation and notify the appropriate authorities

that the testing operation is complete and the system

is active again.

NOTES FOR USING DETECTOR

The National Fire Protection Association (NFPA)

states that duct smoke detector must not used as a

substitute foropen area smoke detectors. Duct

smoke detectors are solely intended to use in the

air handing equipments for such purposes like

dampers or shutting down the air handing units.

NOT SUITABLE FOR INSTALLATION IN

AREAS WHERE AIR VELOCITIES EXCEED

300 ft/min.

MAINTENANCE

The recommended minimum requirement for detector

maintenance consists of an annual cleaning of the dust

from the detector head by using a vacuuming routine

compliant with the NFPA-72A standard.

CAUTION: DO NOT ATTEMPT TO REMOVE

THE SCREWS WHICHHOLDTHE ASSEMBLY

OF THE SMOKE-SENSING CHAMBER ANDPRINTED

CIRCUIT BOARD(PCB). THIS ASSEMBLYIS

SEALED FOR YOURPROTECTION ANDIS NOT

INTENDED TO BE SEPARATED FOR SERVICING BY

USERS. OPENING SUCH ASSEMBLY WILLVOID

THEWARRANTY.

REFER TO THE TECHNICAL BULETIN ISSUE

NO.STSD20080702S01, REV.D, July 02, 2008

SPECIFICATION

Model

2/4

wire

Heat

Sensor

Setting

Voltage

DC

(Min./Max.)

Standby

Current

(Max.)

Alarm

Current

(12/24V)

Surge

Current

(Max.)

Start-Up

Time

(Max.)

Permissible

Current

(Max.)

Cycle

Time

Alarm

contact

Base

Model No.

SF119-4H(12V) 4 135±512V 80μA 30mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SF119-4H(24V) 4 135±524V 80μA 45mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SF119-4 (12V) 4 - 12V 80μA 30mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SF119-4 (24V) 4 - 24V 80μA 45mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SF119-2HL 2 135±510.8~33V 80μA 22/55mA160μA30 Sec.80mA 1-3 Sec. — P/N854001

SF119-2L 2 - 10.8~33V 80μA 22/55mA160μA30 Sec.80mA 1-3 Sec. — P/N854001

SF119-2H 2 135±510.8~33V 80μA 22/55mA160μA30 Sec.80mA 1-3 Sec. — P/N852001

SF119-2 2 - 10.8~33V 80μA 22/55mA160μA30 Sec.80mA 1-3 Sec. — P/N852001

Remark: L- remote indicator output; H-Heat sensor; AR-Auto-reset; B-Sound

2-wire devicesare UL Recognized, the 4-wire devicesare UL Listed

This manual suits for next models

6

Other S Fire Smoke Alarm manuals