S.I.T.A. MIOLED User manual

DISINFECTION SYSTEM

EQUIPMENT FOR THE TREATMENT OF DRINKING

WATER

MIOLED

Installation, Operation and Maintenance Manual

English 07-2021

1

CONTENTS

1.

Introduction................................................................................................................................................. 2

2.

General Principles and Safety Instructions .................................................................................................. 2

3.

Instructions for installation and commissioning of the system ...................................................................... 4

3.1

Installation under the sink 3/8" flexible connections (male delivery and female return): ........................ 5

3.2

Installation in systems with 8 mm pipes:.............................................................................................. 7

4.

MIOLED exploded view (spare parts).......................................................................................................... 7

5.

Technical Datasheet (operative conditions) ................................................................................................. 8

6.

Maintenance ............................................................................................................................................... 9

7.

Warranty Conditions ................................................................................................................................. 10

8.

EC Declaration of Conformity.................................................................................................................... 11

2

1.

Introduction

This manual applies to the below model:

MIO

LED

The UV systems were made by S.I.T.A. s.r.l.

Warning: This equipment requires regular maintenance to ensure the requirements of the drinking water treated

and the maintenance of the improvements as stated by the manufacturer.

These operating instructions contain important information for the operation and maintenance of the equipment.

Please ensure that these operating instructions are carefully read by all relevant persons before putting into

operation, to ensure the safe use of the UV system. The operating instructions are an integral part of the equipment

supply.

Before putting into operation, all the conditions necessary for safe operation of the equipment must be fulfilled.

The installation, commissioning and maintenance of the equipment should only be carried out by qualified

personnel.

The equipment should only be operated by authorized personnel who have been trained accordingly.

No modifications should be made to the equipment without consulting maker, as this could affect the safe operation

of the unit. Maker shall not be held responsible for damage resulting from unapproved modifications.

I

NSTRUCTION

:

The operating instructions are to be kept where they will be accessible for operating and

maintenance personnel.

2. General Principles and Safety Instructions

Information about UV irradiation:

MIOLEDhas been planned specially for destroying harmful bacteria and viruses present in your water.

Their working is based on a physical principle which is a warranty of security: the output of ultra-violet irradiation.

The UV light given out by special mercury vapours lamps (UV-C rays

λ

= 254nm) is highly germicidal because it

interacts with DNA and RNA, at a molecular level.

The deep bio-structural disorder caused by such irradiation interferes with the development and the ability of

reproduction of every kind of micro-organism, making it harmless.

Generally it is better to mount a pre-filter before the UV sterilizer, in this way the impurities of every nature and

consistence are kept.

This system comes to be necessary if we want to have a high degree of sterilization, infact the non-filtration and

removal of suspended particles in the water has, as a consequence, a decrease of the sterilizer's efficiency.

If the water to be treated contains sulphydric acid or more than 0.3 p.p.m. of iron or filtrable solids, once passed

through the sterilizer, it leaves a residual sediment on the quartz sleeve, which, therefore, must be periodically

cleaned (the frequency depends on the quantity and quality of water treated).

General directions:

According to the European rules EN 60204-1 (safety of the set-up off the electrical equipment-general rules) the

low tension electrical instruments (rule 2014/35/CE) must be connected to a current-tap provided with grounding.

Electrical Safety Instructions:

The lightning flash and arrowhead symbol is to alert the user to the presence of un-insulated

"DANGEROUS VOLTAGE” within the enclosure. The equipment may only be opened if main supply

is isolated. The main supply must not be restored as long as the equipment is open. This applies to

both the electrical panel and the UV reactor vessel.

WARNING

: Working on live equipment is forbidden.

3

UV Light Danger:

The light of ultra-violet lamps can cause serious burns to unprotected skin and eyes, therefore it is

recommended not to connect it to the current tap without having before ensured the UV lamp in its

housing and inserted the PVC cover.

Pressure Danger:

The UV chamber could be under water pressure. Max working pressure is 10 bar. UV chamber must be installed

in accordance with our installation and commissioning instructions and used in accordance with operating and

maintenance instructions.

ATTENTION: Ensure that system is depressurized before attempting any service or repair.

Indications for the disposal:

We remind that, according to what is fixed by D.L. 4 May 2014, N°27 "Accomplishment of directive 2011/65/CE,

concerning the reduction of dangerous substances in electric and electronic equipment" both mercury vapours

lamps and electrical panels, when no more used, must be considered as special waste, and in the same way

disposed of.

To do that, it is possible to address to specialized centers for the recovery of dangerous materials, or to contact

directly our technical department.

INFORMATION TO USERS pursuant to art. 14 of the 2012/19 / EU DIRECTIVE OF THE

EUROPEAN PARLIAMENT AND OF THE COUNCIL of 4 July 2012 on waste electrical and

electronic equipment (WEEE)

The crossed bin symbol on the appliance or on its packaging indicates that the product at the end

of its useful life must be collected separately and not disposed of together with other mixed urban

waste.

Please contact your municipality, or local authority, for all information regarding the separate collection systems

available in the area. The retailer is obliged to collect the old equipment free of charge when buying new equipment

of an equivalent type, for the purpose of starting the correct recycling / disposal.

Appropriate separate collection for the subsequent start-up of the disused equipment for recycling, treatment and

environmentally compatible disposal helps to avoid possible negative effects on the environment and on health

and favors the re-use and / or recycling of the materials it is composed of the equipment.

4

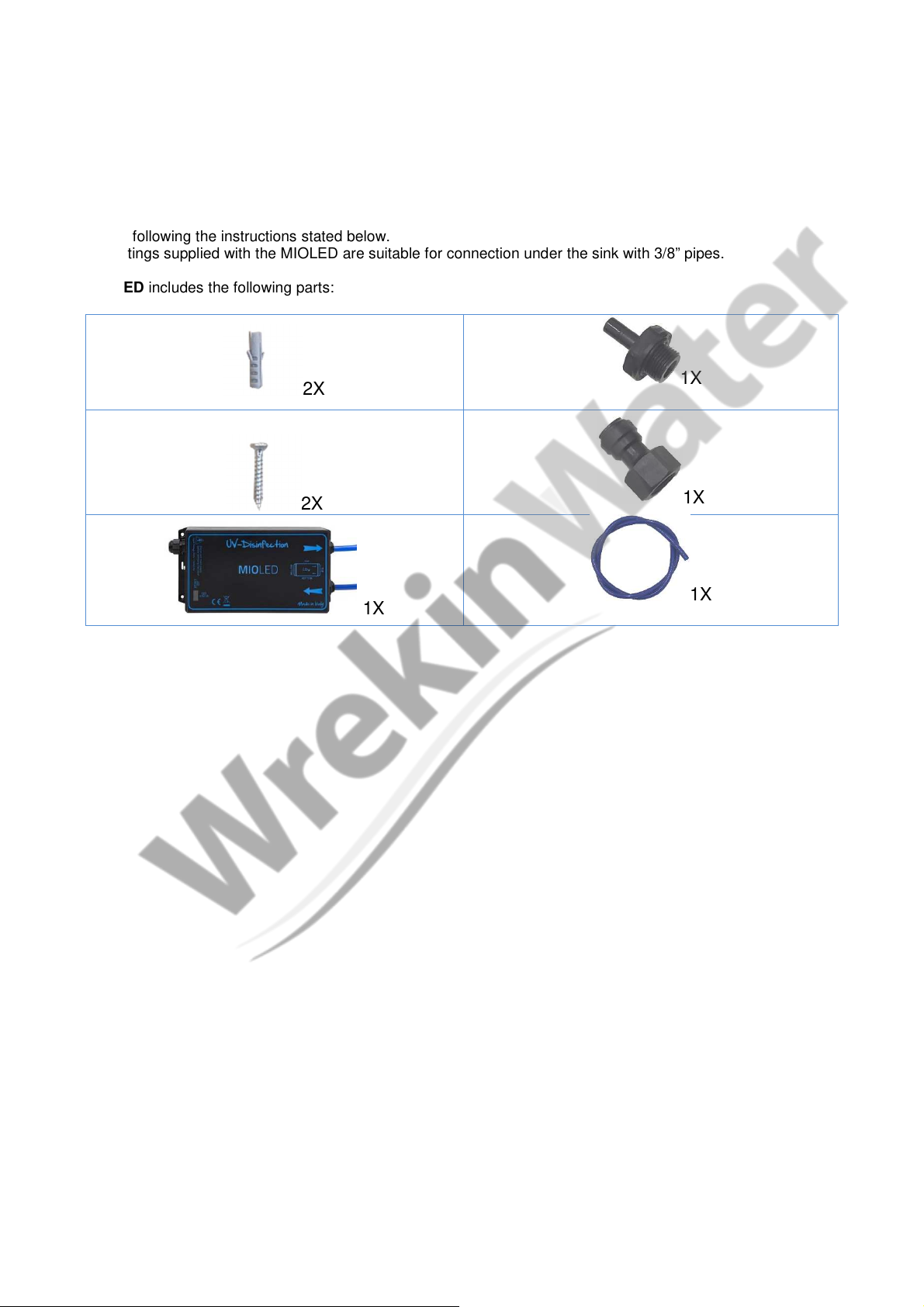

3. Instructions for installation and commissioning of the system

General premise

The installation of the debacterization systems of the “LED” series must be carried out by specialized personnel

strictly following the instructions stated below.

The fittings supplied with the MIOLED are suitable for connection under the sink with 3/8” pipes.

MIOLED includes the following parts:

2X 1X

2X

1X

1X

1X

5

3.1 Installation under the sink 3/8" flexible connections (male delivery

and female return):

Warnings: Check that MIOLED is disconnected from the mains, that the raw water valve is closed and that the

tap is open.

Install MIOLED on the wall with the fisher supplied:

6

- Stop the flow of water to the tap.

- Disconnect the 3/8” male union of the

delivery hose. Connect it to the female fitting

supplied. Connect the 8 mm plastic tube to the fitting.

- Connect the 3/8” female fitting of the delivery

hose to the male fitting supplied.

- Connect the IN and OUT of MIOLED respecting the inlet and outlet described by the arrows on the label (below

example with a flexible 3/8 "female tap):

- Open the inlet water supply and check that there are no water leaks in any part of the system.

- Connect MIOLED to the electricity.

- Check that the sterilized water comes out and the LED is on the STATUS LED window (the LED lights up

only when water flows).

- Let the disinfected water flow out for at least 10 minutes before using it, in order to purge any impurities,

present in the system.

NOTE: It is recommended to install a water filter directly before the UV sterilizer in order to remove any suspended

particles present in the water to be treated, which could limit the disinfection effectiveness.

7

3.2 Installation in systems with 8 mm pipes:

Connect the IN and OUT of MIOLED respecting the input and output described on the label:

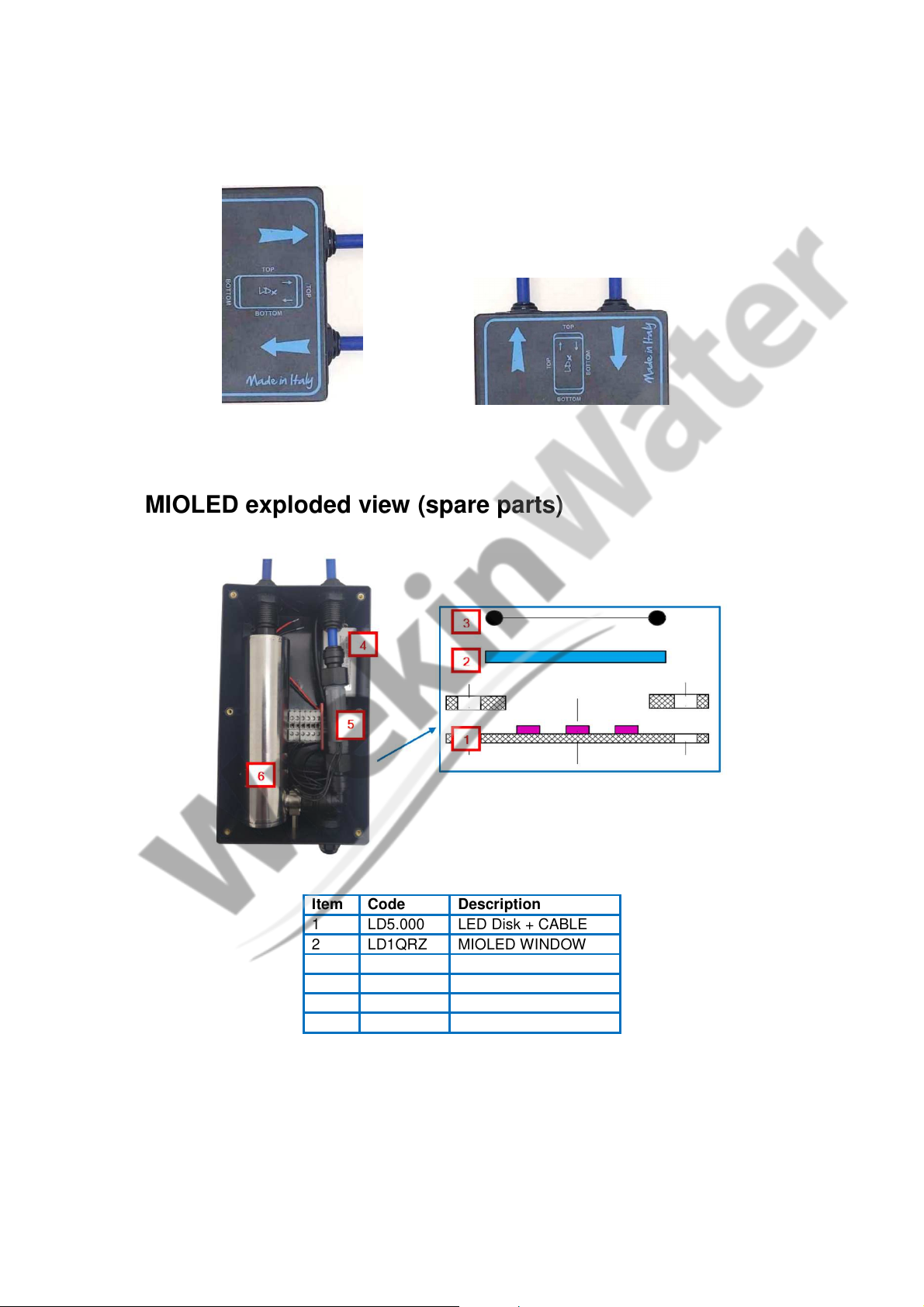

4. MIOLED exploded view (spare parts)

Item

Code

Description

1 LD5.000 LED Disk + CABLE

2 LD1QRZ MIOLED WINDOW

3 LD1OR ORING OF SEAL

4 LD1BLST IGNITOR LD1

5 LDA277 3/8 "FLOW SWITCH

6

LD1R

LED REACTOR

8

5. Technical Datasheet (operative conditions)

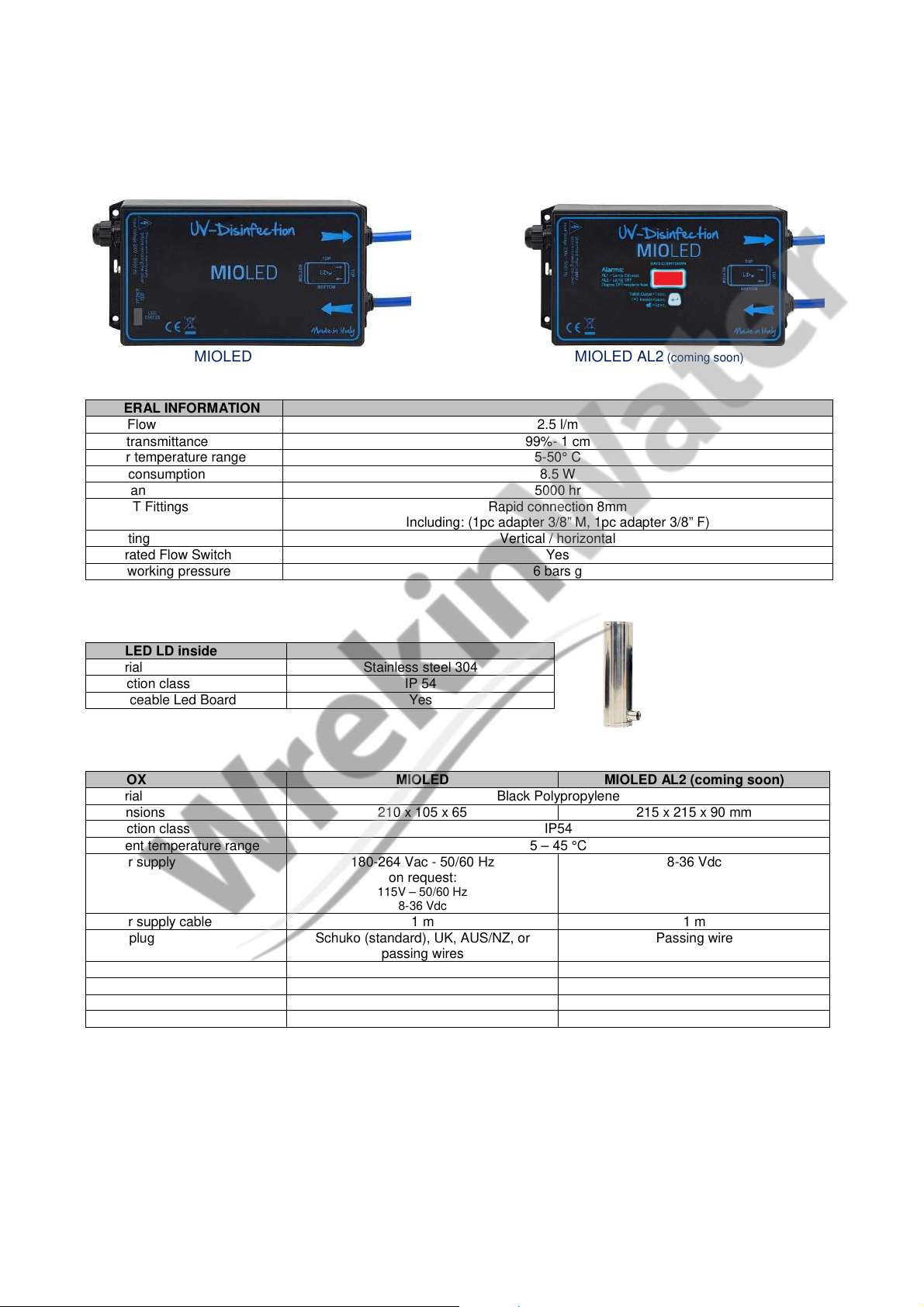

MIOLED

MIOLED AL2

(coming soon)

GENERAL INFORMATION

Max. Flow 2.5 l/m

UVC transmittance

99%

-

1 cm

Water temperature range 5-50° C

Total consumption

8.5

W

Lifespan 5000 hr

IN-OUT Fittings Rapid connection 8mm

Including: (1pc adapter 3/8” M, 1pc adapter 3/8” F)

Mounting Vertical / horizontal

Integrated Flow Switch

Yes

Max. working pressure 6 bars g

SITALED LD inside

Material Stainless steel 304

Protection class IP 54

Replaceable Led Board Yes

UV BOX

MIOLED

MIOLED AL2 (coming soon)

Material Black Polypropylene

Dimensions

210 x 105 x 65

215 x 215 x 90 mm

Protection class IP54

Ambient temperature range 5 – 45 °C

Power supply 180-264 Vac - 50/60 Hz

on request:

115V – 50/60 Hz

8-36 Vdc

8-36 Vdc

Power supply cable 1 m 1 m

Feed plug Schuko (standard), UK, AUS/NZ, or

passing wires

Passing wire

Monitor display Status LED Digital SITA

Days meter NA Yes for total system life

Resettable

days

meter

NA

Yes for

led

life control

Audio alarm NA With silence options

Rev.2

9

6. Maintenance

Maintenance must only be carried out by personnel who have been trained and authorized for this work

by the owner and / or user.

The owner and / or user must be sure that maintenance personnel are familiar with the safety measures

and regulations, and that they comply with them; in addition, he must have read and understood the

operating instructions.

Only original spare parts from the supplier should be used.

These are the recommended intervention intervals for spare parts:

LED disk (code

LD5.000

): MIOLED turns on only when the water passes, optimizing the life of the LEDs

themselves. Replace the led disk every 3000 hr of operation (8 years if it works on average 1 hr / day, 4

years if it works 2 hr / day .......)

Sealing O-ring (code LD1OR): recommended annual check. Replacement at the first sign of abrasion.

MIOLED window: A clean MIOLED window increases the effectiveness of disinfection. The frequency of

cleaning depends on the quality of the treated water, check annually.

Procedure for replacing the LED disk (5000 h max.)

1. Uninstall MIOLED from the mains and from the water mains (see assembly procedure).

2. Detach MIOLED from the wall and empty it of residual water.

3. Open the MIOLED bottom cover.

4. Unscrew the ring nuts of both bulkheads and push the LED reactor / flow switch KIT to be able to

intervene on the base of the LED reactor where the LED disc is located:

1. Unscrew the small fixing screws of the LED disc.

2. Disconnect the LED disk wire from the terminals.

3. Connect the new LED disk to the terminals taking care to respect the colors of the wires.

4. Reassemble and hydraulically test.

Procedure for cleaning the quartz LED window

1.

Repeat steps 1 through 5 from the previous section

2. Remove the quartz and clean it by wiping it with a cloth soaked in a weakly acid solution (vinegar or lemon)

3. Reassemble

10

7. Warranty Conditions

WARRANTY CONDITIONS

SITA

works in compliance with ISO 9001-2015 quality procedures and subjects all

equipment to accurate checks and tests.

The SITA supplies and progressing are anyway guaranteed only in the limits of

technical specifications and request and/or of the certificates and/or of the specific

checks as agreed, for 24 months from the delivery date or 30 days from the purchase

date, provided that eventual defects are stated as fixed by art. No. 1495 of the civil

code.

The stainless-steel chamber is covered by warranty of 5 years only if used for

compatible liquids and correctly installed.

In no case the integral replacement of the product is foreseen and any responsibility of

SITA is excluded for delays in the delivery of the goods to the customer, for claims of third

parties towards the customer, for losses of goods, costs (installation, servicing and

maintenance, transports, and so on) and damages of the customer due to the defect.

Moreover, the product repaired or tampered by non-authorized third parties, and the

product on which an intervention has been made for defect of for convenience tests, is

excluded from the warranty.

Repairs are normally carried out in SITA warehouse or in authorized after-sales service

centres signalled by SITA.

The warranty does not cover:

1. Accidental breakages due to the transport.

2. Breakages due to the use of equipment not in compliance with what is indicated on the

use and maintenance manual or to carelessness.

3. Breakages to the connection to a power grid fed with a tension different than the

foreseen one (±10% of the nominal value as fixed by CEI rules)

DO NOT TAMPER THE ADHESIVE LABELS OF IDENTIFICATION

The adhesive label with the QC (Quality Control) number must be intact and readable; such

number allows to enter the data bank of tests and to find the values obtained in the electrical

test of the equipment.

The adhesive label with the S/N (Serial Number) number must be intact and readable; such

number allows to enter the data bank of tests and to find the values obtained in the hydraulic

test of the equipment.

In case of dispute the court of Genova will be competent.

11

8. EC Declaration of Conformity

Unit produced in the factory of:

S.I.T.A.

Italian Air and Water Treatment Company

EC DECLARATION OF CONFORMITY

The undersigned hereby declares, under full responsibility, that the unit:

UV DISINFECTION SYSTEM

LED SERIES

MOD. MIOLED

IS ACCORDING TO

the provisions of Community Directives and Regulations:

• 2014/35 / EU (low voltage directive)

• 2014/30 / UE (electromagnetic compatibility)

• 2015/863 / UE (RoHS3)

• 2012/19 / EU (WEEE)

• Standard CEI -EN 60204-1 (safety - electrical equipment of the machine)

• Standard CEI -EN 55022 (radio disturbance characteristics)

• Ministerial Decree 25/2012 (Technical provisions concerning equipment for the treatment of water

intended for human consumption)

• Ministerial Decree 174/2004 (materials in contact with drinking water)

• Ministerial Decree 14 June 2017 (Implementation of Directive 2015/1787 / EU relating to the quality

of water intended for human consumption)

• 2014/68 / EU (Article 4 paragraph 3) (PED)

The authenticity of the CE marking is subject to the credibility of the unit. If any change is not

allowed, the use of the CE marking will be cancelled. It might arise in the event that our

organization has not already assessed the related risks and a new EC Statement of Compliance

has been released.

This manual suits for next models

1

Table of contents