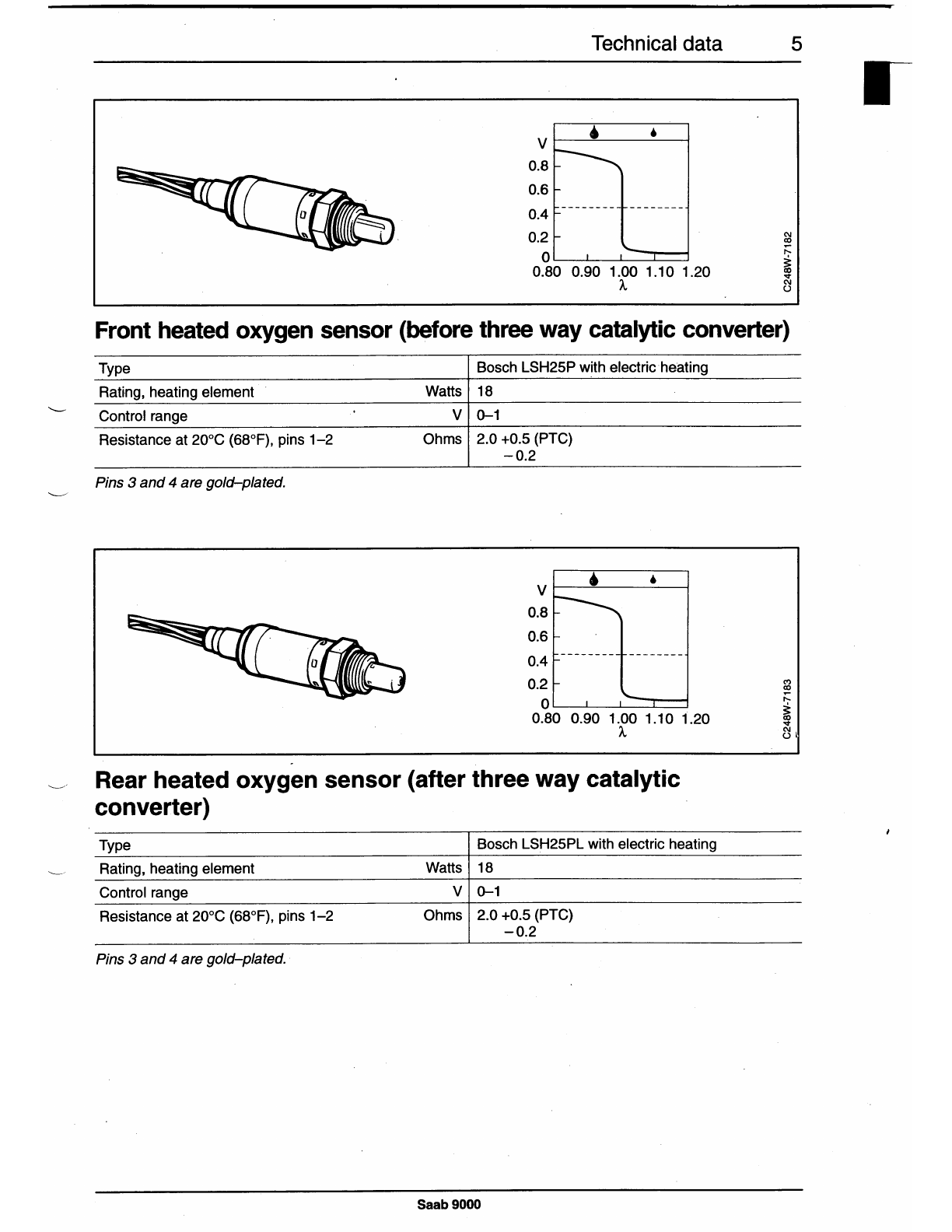

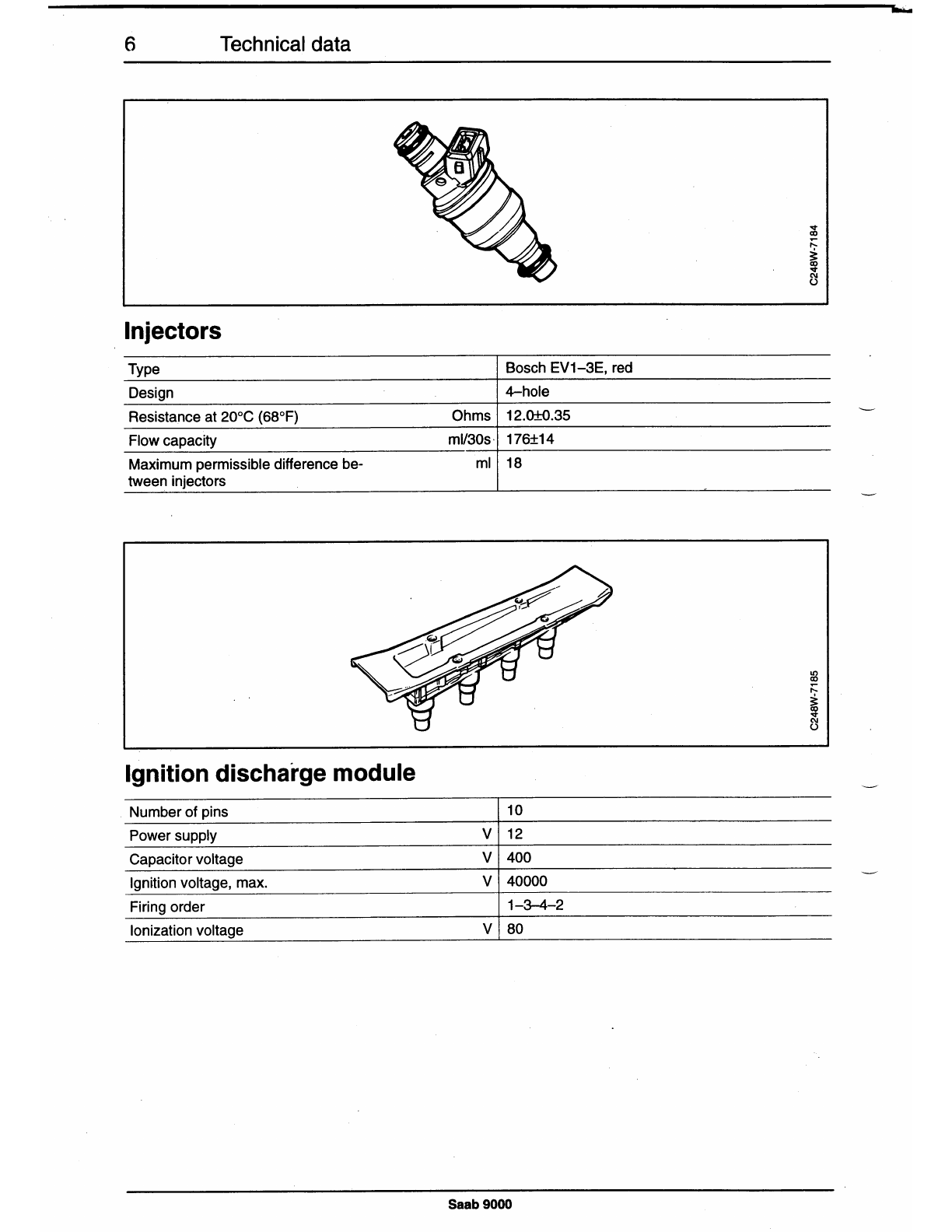

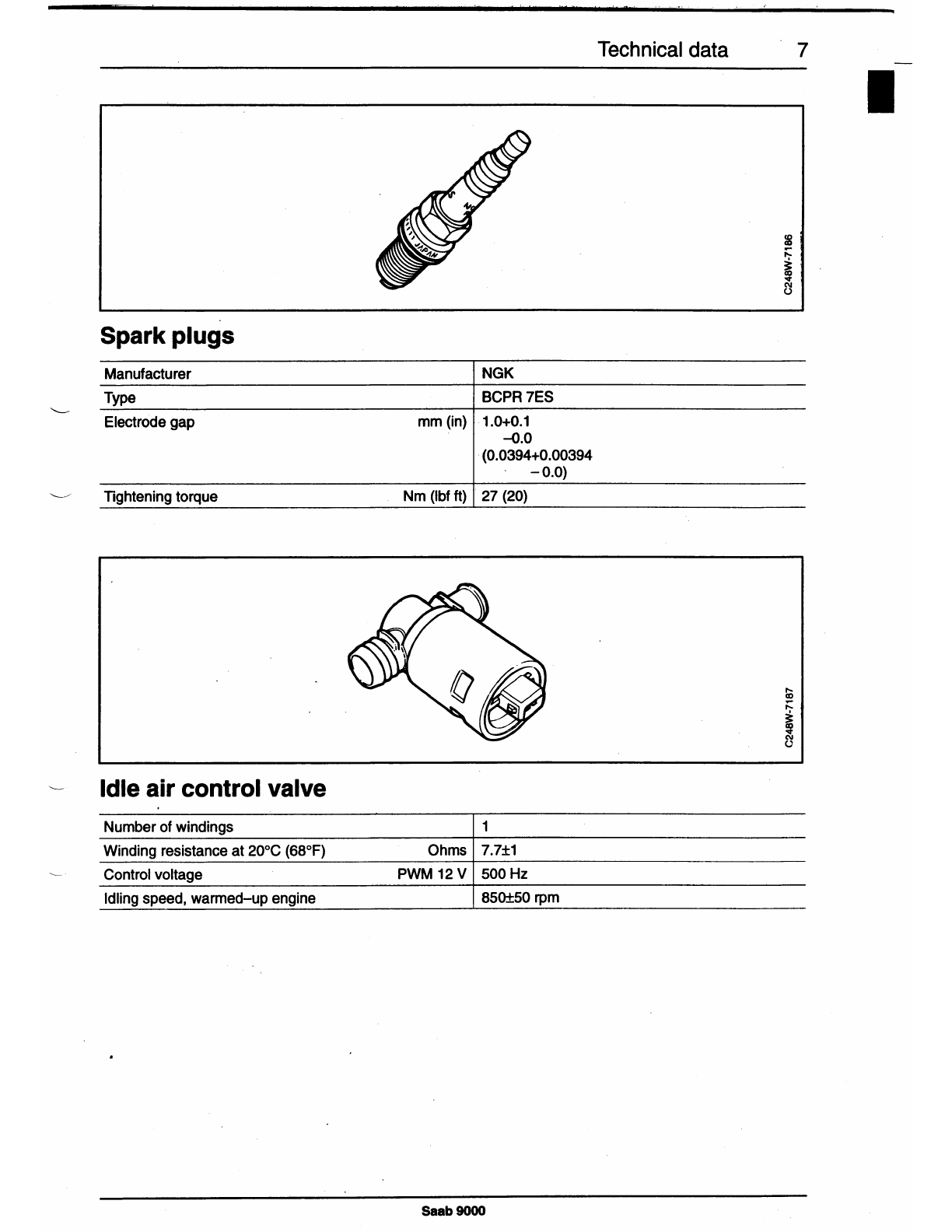

Saab 9000 User manual

Other Saab Automobile manuals

Saab

Saab 2006 9-7X User manual

Saab

Saab 1996 NG900 User manual

Saab

Saab 9-3 User manual

Saab

Saab 2003 9-5 2.3 Turbo Ecopower User manual

Saab

Saab 95 2010 User manual

Saab

Saab 2007 9-7X User manual

Saab

Saab V4 User manual

Saab

Saab 2000 9-5 2.3 Turbo Ecopower User manual

Saab

Saab 2002 9-5 2.3 Turbo Ecopower User manual

Saab

Saab 900 1983 User manual

Saab

Saab Sonett III User manual

Saab

Saab 9-7X User manual

Saab

Saab 1987 900 User manual

Saab

Saab 2006 9-5 User manual

Saab

Saab 2005 9-3 Remote Starter User manual

Saab

Saab 2004 9-3 Remote Starter User manual

Saab

Saab 9000 M 1998 User manual

Saab

Saab 2007 9-3 Remote Starter User manual

Saab

Saab 9-5 2011 User manual

Saab

Saab Monte Carlo 850 User manual