5

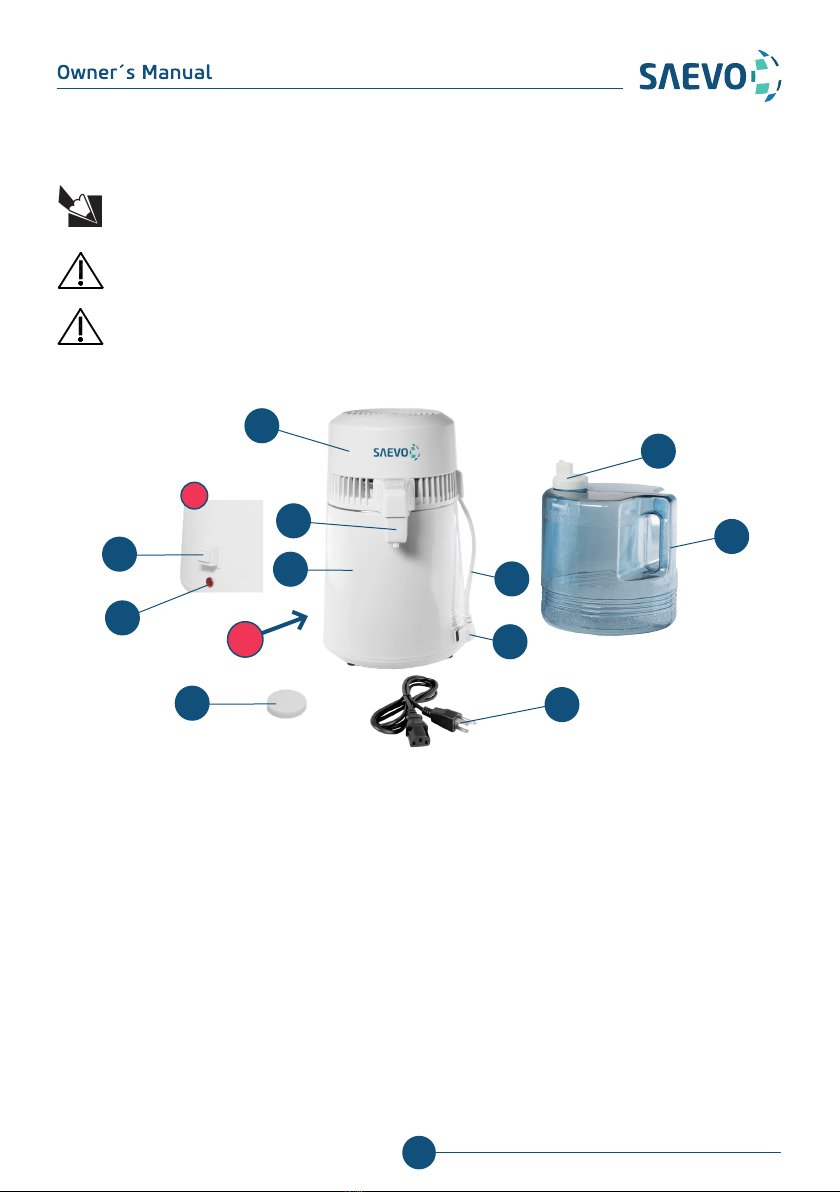

Description of Equipment

The portable Bio Aqua water distiller totally eliminates the total dissolved solids (minerals, heavy

metals, toxins, or any other contaminant).

- It has high capacity "4Liters": sucient volume for many dierent uses;

- Purify water up to 99.9%, meeting all required standards;

- It is portable and easy to install;

- Robust and easy to clean, entirely thermoplastic-covered cylindrical body;

- Internal stainless steel vat: durability and ease of cleaning;

- Manual supply, it does not require hydraulic installations;

- It has automatic power-o function after each distillation cycle.

Principles and bases applied to the functioning of the product

As in the water cycle in nature, the cycle begins when the sunbeams warm waters of the seas and

rivers forming water steam that rises into the air (evaporation) when the vapor cools down clouds

are formed (condensation) and when they become heavy they eliminate water back through the

rain (precipitation).

In Bio Aqua water Distiller, water is boiled in the boiling chamber and when it reaches a temperature

of 100ºC, bacteria, viruses and other organisms that may be present are killed. Boiling water turns

into steam, eliminating dissolved solids, chemical toxins, heavy metals and other contaminants.

The steam rises through the condensation coil, it is cooled and condenses into drops of pure water.

After this process, the water still passes through an activated charcoal lter (optional), eliminating

odors and avors. Pure water is collected in a plastic bottle provided with the product.

Indication of Equipment

The Bio Aqua water Distiller is indicated for use in autoclaves, laboratories, compounding pharmacies

and all procedures that require use of distilled water.

It should be used and handled by qualied person (professional personnel properly regulated

according to the local legislation of the country) following the instructions in this manual.

It is the user's obligation to use only the device in perfect conditions and protect him/herself,

patients and third parties from eventual dangers.

ACTIVATED COAL FILTER:

- When distilled water is indicated for human consumption, shall be purchased the activated

coal lter therefore water has a much more good fresh taste (optional item available for sale).

IDENTIFICATION OF EQUIPMENT