1) Connect the DC plug to the adaptor connector of control box.

4-1. Battery charging

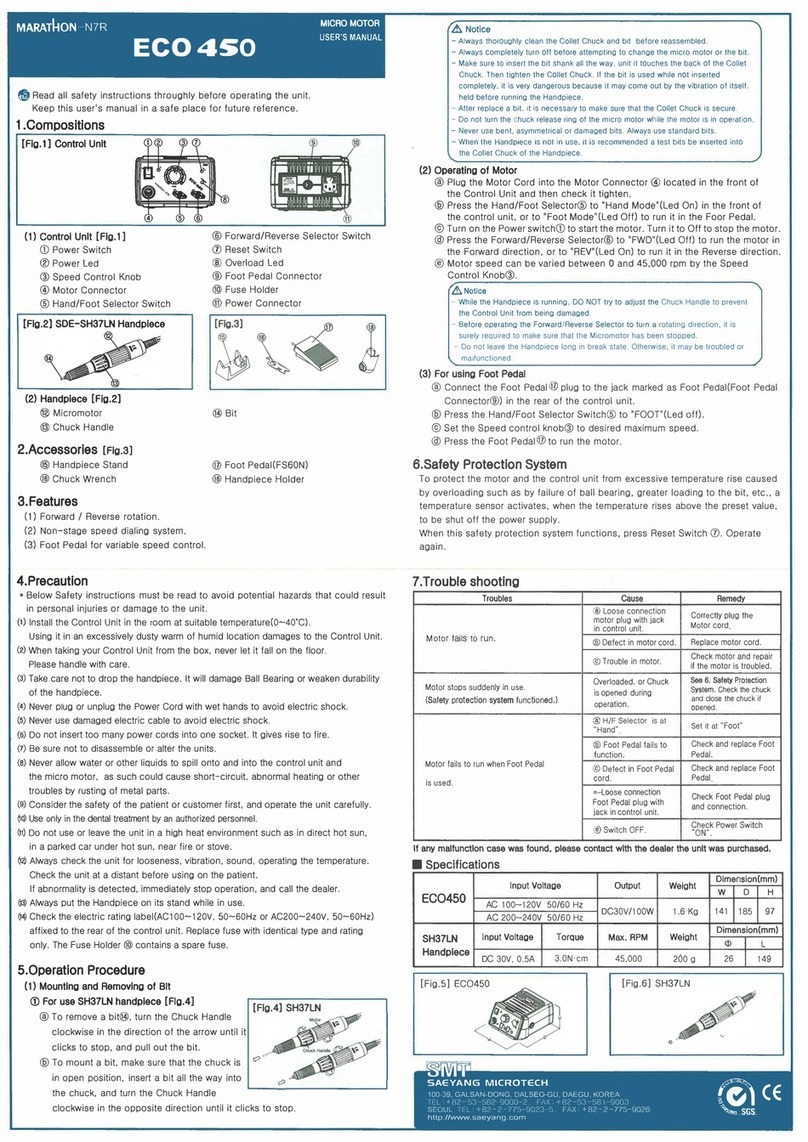

Power on/off & speed control Knob

Charge display LED

Speed display LED White >> Sky Blue >> Blue >> Pink

Pause button

Forward/Reverse switch

Handpiece connector

Front panel

Control box

Handpiece

Handpiece stand

Control box stand (optional)

Adaptor

Clip(optional)

Handpiece holder (optional)

Max speed : 30,000 RPM

Run-time

Charging time : 3 hrs.

Speed control

Forward / Reverse rotation

Overload protection

Use with the standard bit

The battery is a Li-ion rechargeable battery(consumable goods)

Battery lifetime is limited and depends on working conditions.

Please dispose used batteries in accordance with the national and local laws.

Install the unit at your workplace and do not use in a dirty or very hot and humid

environment.(-20℃~ 40℃, 0-90% RH)

Please take care not to drop the handpiece or drill unit. This will result in damage

to ball bearing and will affect the durability of the motor.

Please do not allow water or other liquids to spill onto and into all units.

After replacing a bur, please make sure to close the chuck handle.

Do not open the chuck handle while the handpiece is in operation.

While the handpiece is not in operation, it is recommended to leave a drill bit (bur)

inserted into the chuck after cleaning

MINI cro is a professional use only device, for use by professionals only.

1. Precaution

2. Features

3. Part introduction

※Please be sure to read this manual before operation.

Portable control box & Micro-motor

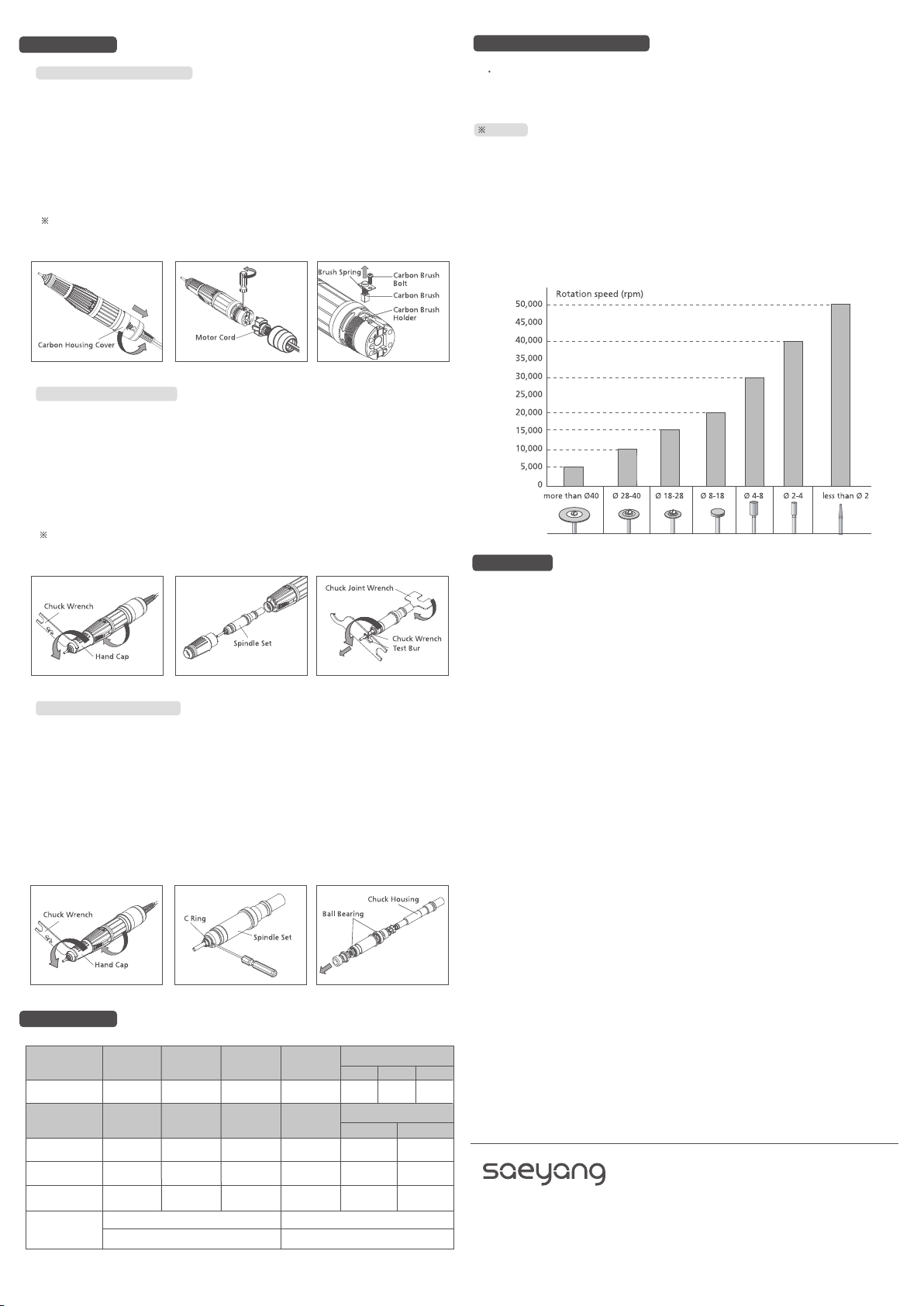

20,000 RPM

30,000 RPM

30,000 RPM

9hrs

10hrs, 4hrs

6hrs

SDE-MH20(30K), SDE-SH300

SDE-MH20

SDE-H200

②③④⑥ ⑦⑤

Clip Type

(Optional)

Standard type

Back viewSide viewFront view

madein korea

4. Installation & Operation

See No.6 Safety protection system.

Check the chuck and close the chuck.

Check the motor and repair if the

motor has a problem

Replace the motor cord.

Replace the carbon brushes.

Correctly plug the motor cord to the

motor connector of control box.

Worn carbon brushes.

In case any malfunction is found, consult with an official dealer.

Trouble in the motor part.

Defect in the motor cord.

Motor stops suddenly

while in use.

Although a control

box is fully charged,

a handpiece fails to

run.

Loose connection of a

motor cord with the motor

connector of control box.

(1) To remove a bur, please turn a chuck handle clockwise until it clicks to stop, and

then pull out the bur.

(2) To insert the bur, please turn the chuck handle counterclockwise until it clicks to

stop.

(3) Please be sure not to use bent, asymmetrical or damaged burs. Always use stand-

ard burs.

5. Bur(Bit) insertion and removal

4-3. Pause Funtion

1) If you press the Pause button during handpiece operation, the operation

of the handpiece is temporarily stopped.

2) Press the Pause button again to start the handpiece operation.

1) Connect the handpiece to a control box.

2) Turn the power on / off & speed control knob to the right SPEED LED turns

white and power is on.

3) Turn the Power on/off & speed control knob to the left or right to use the

minimum and maximum rpm.

4) Forward / Reverse can be selected using Forward / Reverse switch

4-2. Operation by Hand

To prevent from overheating, please be sure to separate the adaptor from the

control box. Also,please avoid operating the unit during charging hours.

When charging, please make sure to use the original charge adapter and

power cord.

2) The CHG LED lights up RED while the battery is charging, and the CHG LED

lights up GREEN when charging is complete

6-1. Overload protection function

: During overload, the speed display LED turns red and flashes, and the current

is cut off. Turn the knob to the left to turn off the power or press the pause

button, release the cause of the overload, then turn the power on or release

the pause to use again.

6. Safety protection system

Overloaded or a chuck is open i

in operation.

(low speed) (high speed)

made in korea

Warning about battery usage