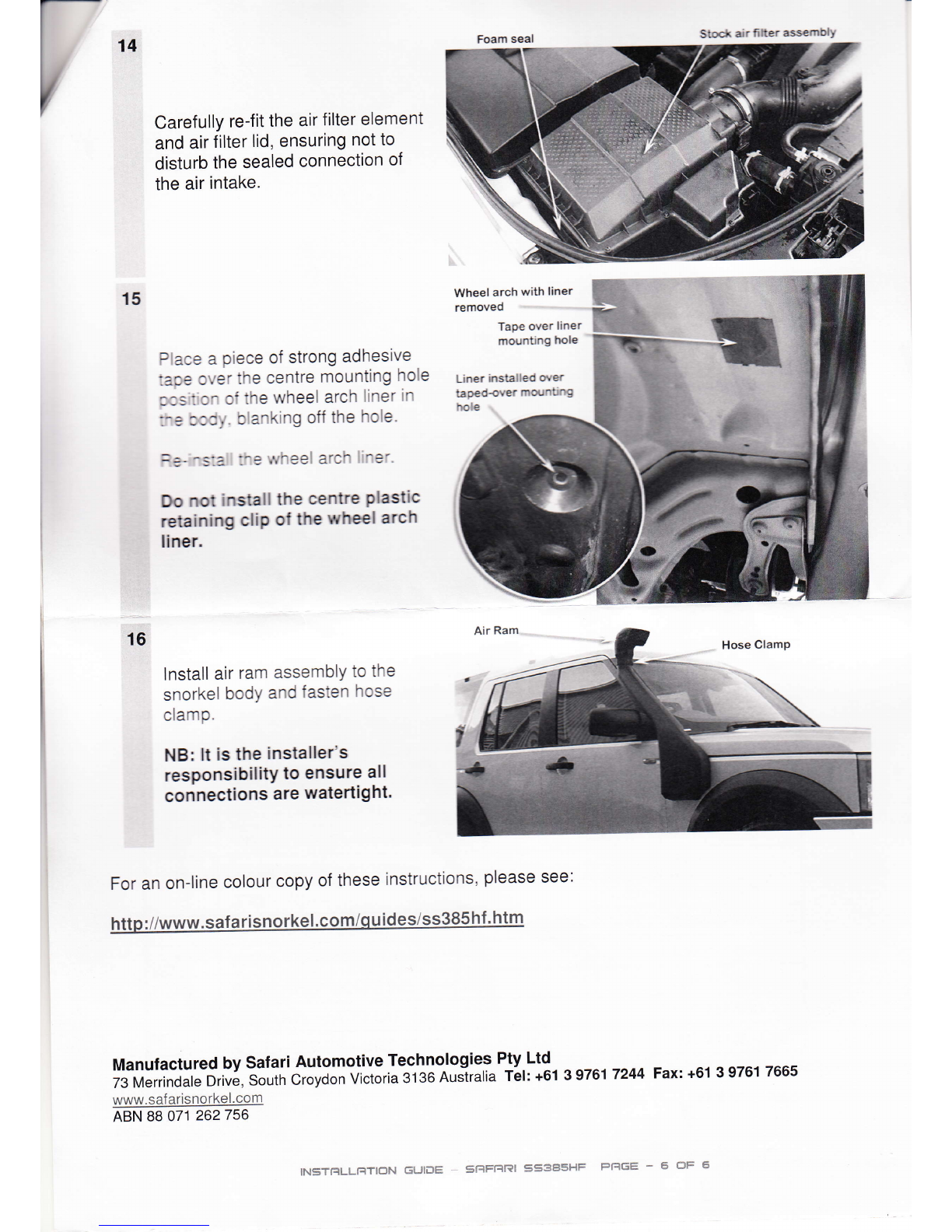

10 Hose Clar;

{

Drill the 3 connecting duct

mounting hole Positions to 5mm

and secure the connecting duct to

the inner guard Panel using PoP

rivets (ltem no.5).

lnstall the 3 x 6mm studs and 2 x

3-- studs into the snorkel bodY

-se1s Dcsition the hose cla-c

= ^ -ea hose and aa'?'-

- -- ! -r

-::a .-3 s-:'<er bodY on:c:-3

^ .f3 C^^/{^ ^^^

--1 - v _ - J

. F.Ä.F:

'r =: - -= -'-.' -- ---''

=-^ .--<_=-

--: - - =- - =-- -

the sncrrte c33r :3 3-a'3 a^3

upper mounting bracket using

necessary hardware. With the

cuffed hose correctlY Positioned

onto the snorkel bodY snout, fasten

the hose clamP.

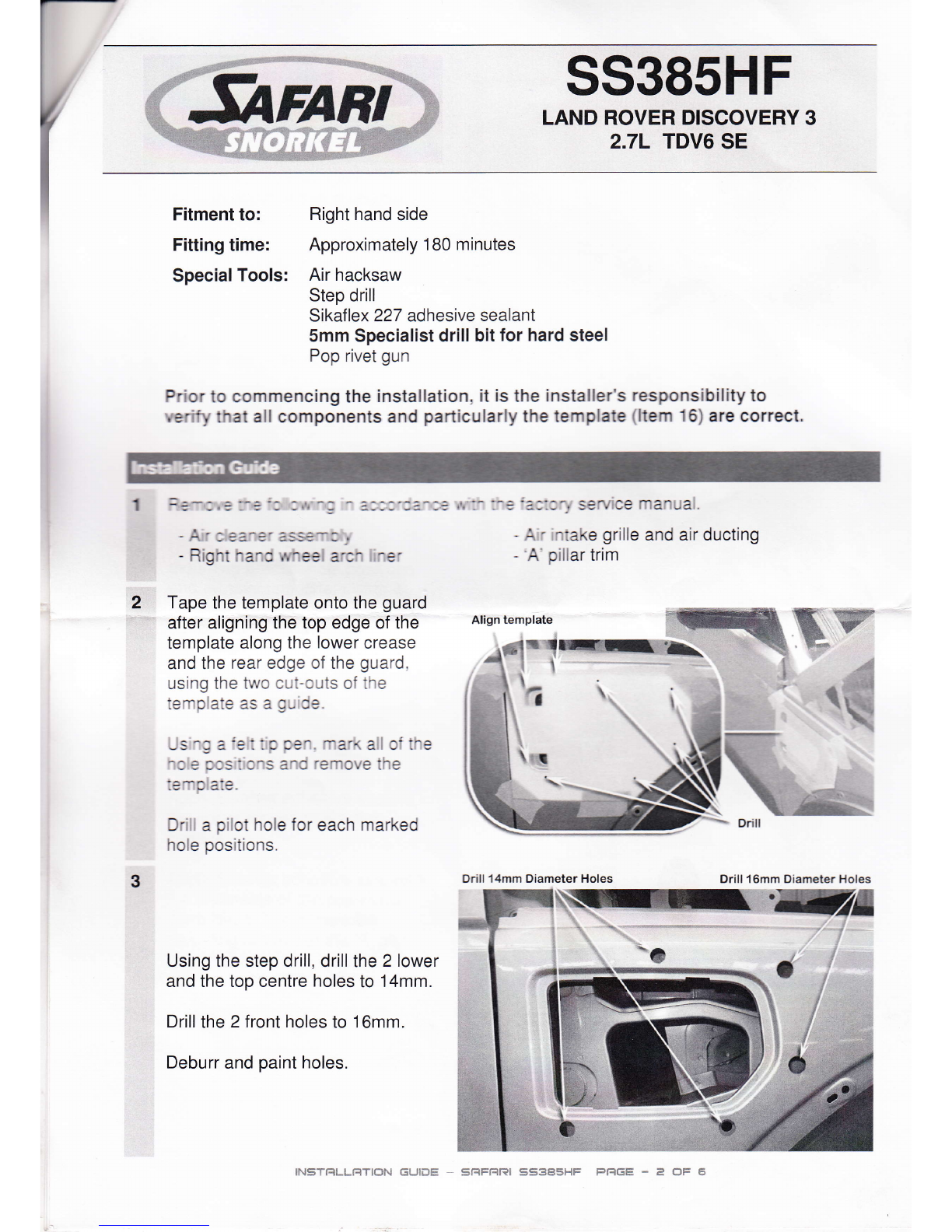

Remove the self-adhesive backing

f rom the foam seal (ltem No. 15)

and secure to the connecting duct.

Apply a liberal amount of Sikaf lex

adhesive sealant to the inside of

the connecting duct and around the

intake snout and f lange of the air

filter housing, to ensure a

watertight connection is achieved.

Carefully re-install the air filter

housing into position, ensuring all

surfaces seal together correctly.

llcse ClamP with head

facing wheel well Cuffed Hose

11 Sno-kel &oc-'

\{,

13 APPIY Sealant

".. around edge

Drill & Pop-Rivet

/

lg

12 With the snorker body correctry sec-.eo to the guard and upper mounting bracket. check

the clearance o, l-e s^c.<e cct le a:rve to thä bonnet rn the open and closed oositrcn 4

,eC-'33 re-3 3^:.e SrSr(e bOJl'O':'e guard tO aChieve adeCuate clearalCe

Peel off adhesive

backing and

place over

- duct

li'{§T'Sq [*!-l--{T iÜ1",} {§Llt*§: §ft§{El?i §S§§§!{!* pfiGH * ä ils ffi