1. INTRODUCTION ...........................................................................................................3

1.1 SAFETY INSTRUCTIONS................................................................................3

1.2 DELIVERY OF UNITS ......................................................................................3

1.3 OVERVIEW OF UNIT TYPES ..........................................................................3

1.4 BASE OPTIONS ...............................................................................................4

2. INSTALLATION.............................................................................................................9

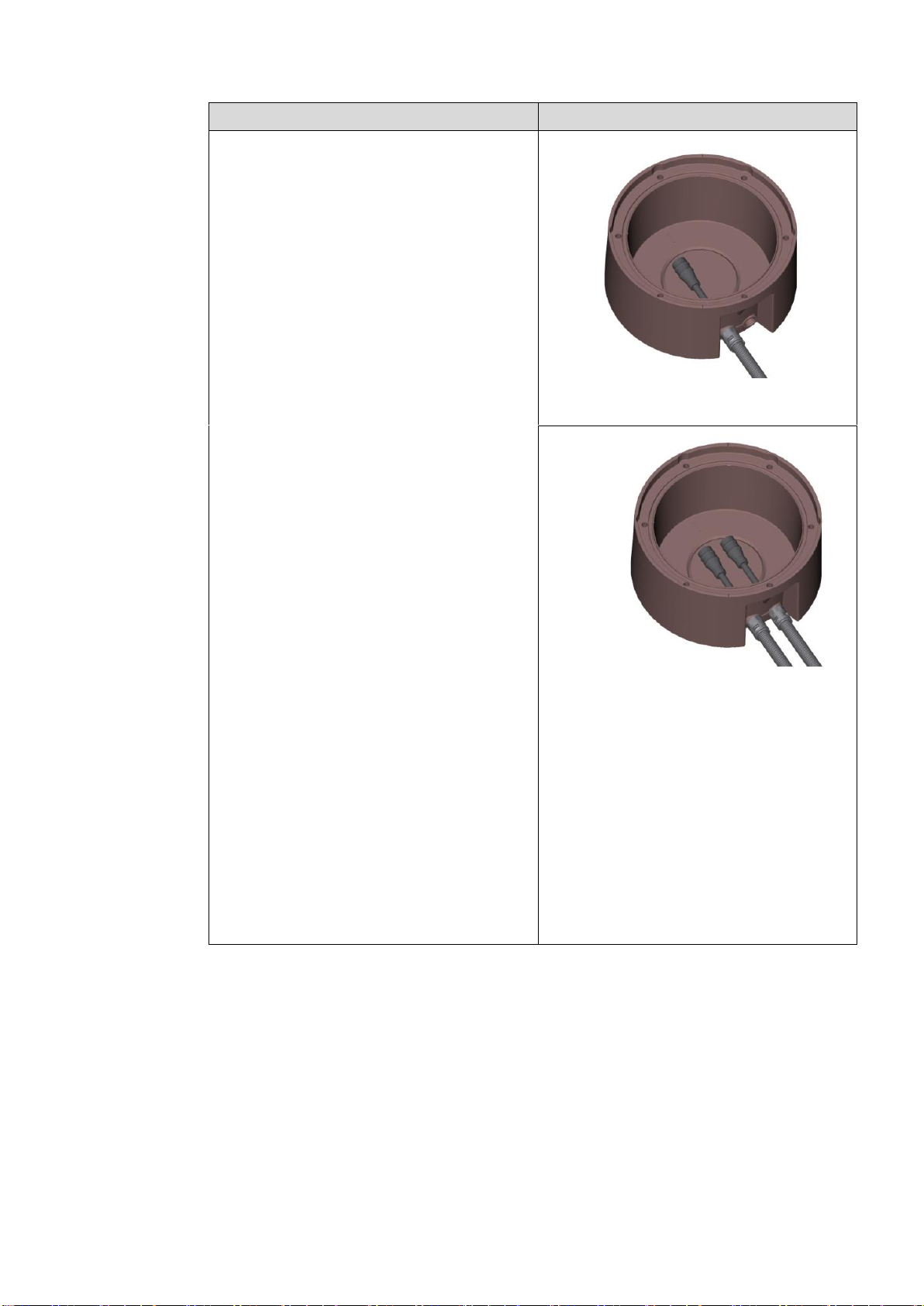

2.1 CABLING OPTIONS.........................................................................................9

2.2 CIVIL WORKS.................................................................................................10

2.2.1 Conduct ....................................................................................................10

2.2.2 Coring........................................................................................................10

2.2.3 Final Preparation......................................................................................11

2.3 ELECTRICAL CONNECTIONS ......................................................................12

2.3.1 Electrical Connections in Base with Bottom Access...........................12

2.3.2 Electrical Connections in Base with Side Access................................13

2.4 INSTALLING THE BASE................................................................................15

2.4.1 Positioning and Alignment of a Base ....................................................15

2.4.2 Fixation of a Base....................................................................................21

2.5 INSTALLING A FITTING.................................................................................22

3. MAINTENANCE ..........................................................................................................23

4. SUPPORT....................................................................................................................24

4.1 SAFEGATE GROUP WEBSITE .....................................................................24

4.2 RE-CYCLING..................................................................................................25

4.2.1 Local Authority Re-cycling .....................................................................25

4.2.2 Safegate Group Re-cycling.....................................................................25

4.3 SPARE PARTS & ACCESORIES...................................................................25