DOCUMENT NO: M40 ISSUE NO: 3 ISSUE DATE: 11/07/18

INSTALLATION AND ASSEMBLY INSTRUCTIONS

Contents of Packaging (as standard):

-Pre-filter (fitted). - Operational manual.

-Main filter . - Quality Pass.

-Allen key. - Service and Maintenance Letter.

-Mains power lead. - Conformity certificates.

-Safety Log Book. - Warranty form.

Your Airone FC750 fume cupboard should be assembled and sited by specialists using

the correct handling equipment. Please contact Safelab systems for assistance in this

matter.

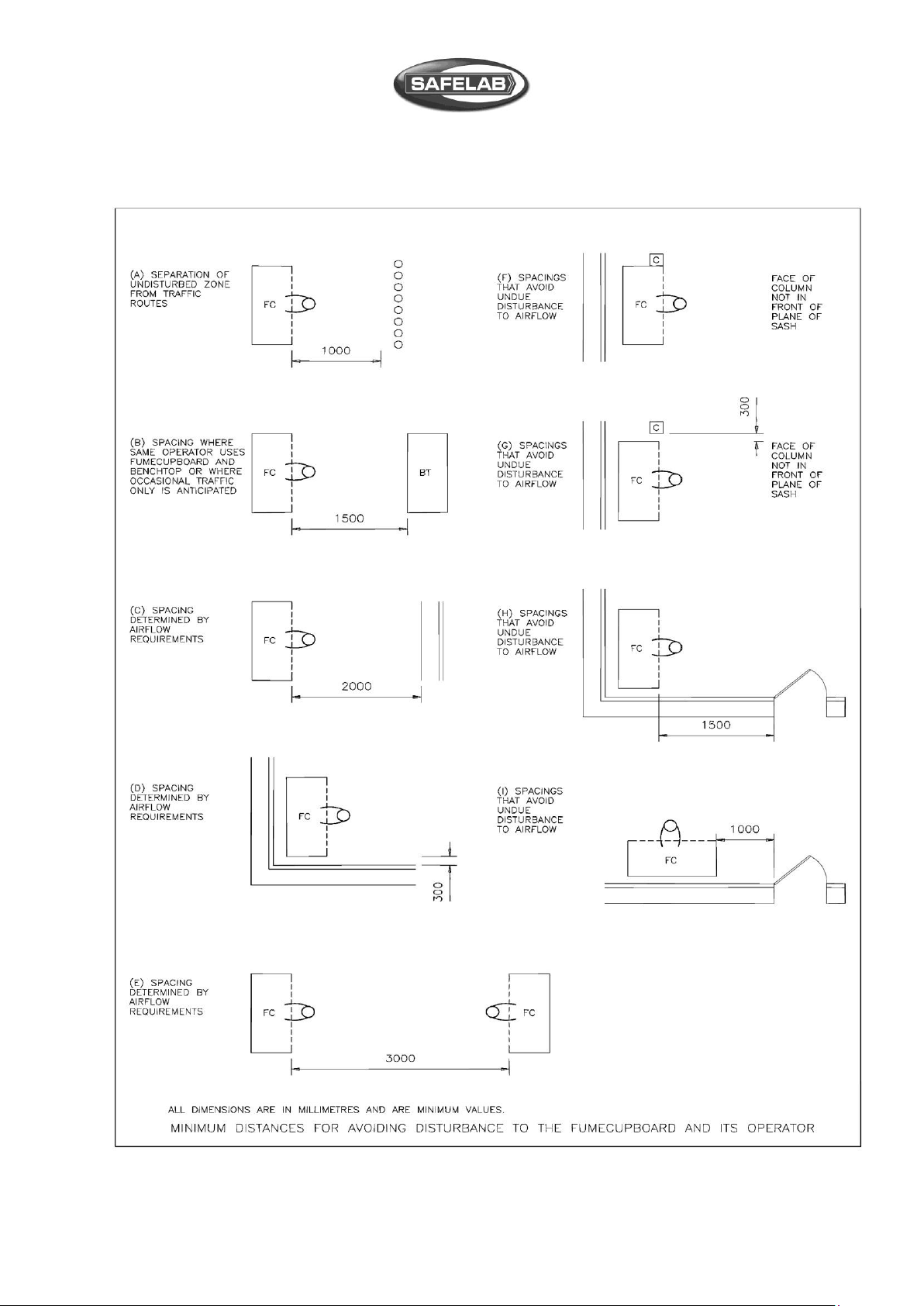

Space for free air circulation must be provided around the Airone FC750 Filtration Fume

Cupboard (see page 6 for a guide to siting the cupboard).

FILTER INSTALLATION (SEE ALSO SPECIFICATION DIAGRAM ON PAGE 8):

1. Ensure cupboard is switched off. Remove the outer front fascia panel by removing

the four Allen screws.

2. Remove the two Allen screws securing the light. Lift the light assembly clear, and

unplug it if necessary.

3. Unpack the main filter and prepare suitable equipment for its safe handling and

installation.

Before lifting the main filter please note that a size B filter weighs approx.

15kg, and may require two people to safely handle it.

Slide the filter gasket side down between the guides in the filter chamber (if using

HEPA/carbon filter, the HEPA is the lower filter, unless the unit is sited in a clean

room, in which case the HEPA filter will be the upper one).

Use the thumbscrews on the filter/fan plenum to evenly clamp the filter in

position.

4. Fill in the date on the filter identification label and stick it to the front of the filter,

ensuring it will be clearly visible through the viewing window on the cover panel.

5. Replace both the light unit and front cover panel and retaining screws, ensuring

the lighting plug is reconnected.

6. Following this procedure, it is recommended that the filter monitoring procedure

detailed in the Operational Safety Manual is performed. This ensures correct

seating of the filter within the cabinet.

Written records of filter monitoring are a legal requirement under COSHH.

7. Connect to the power supply and the cabinet is ready for commissioning.

See Calibration instructions on page 12.