MAXILUBE

IF-105

MUIF3AEN.doc 21.4.2005 Rev. 3A

6 (9)

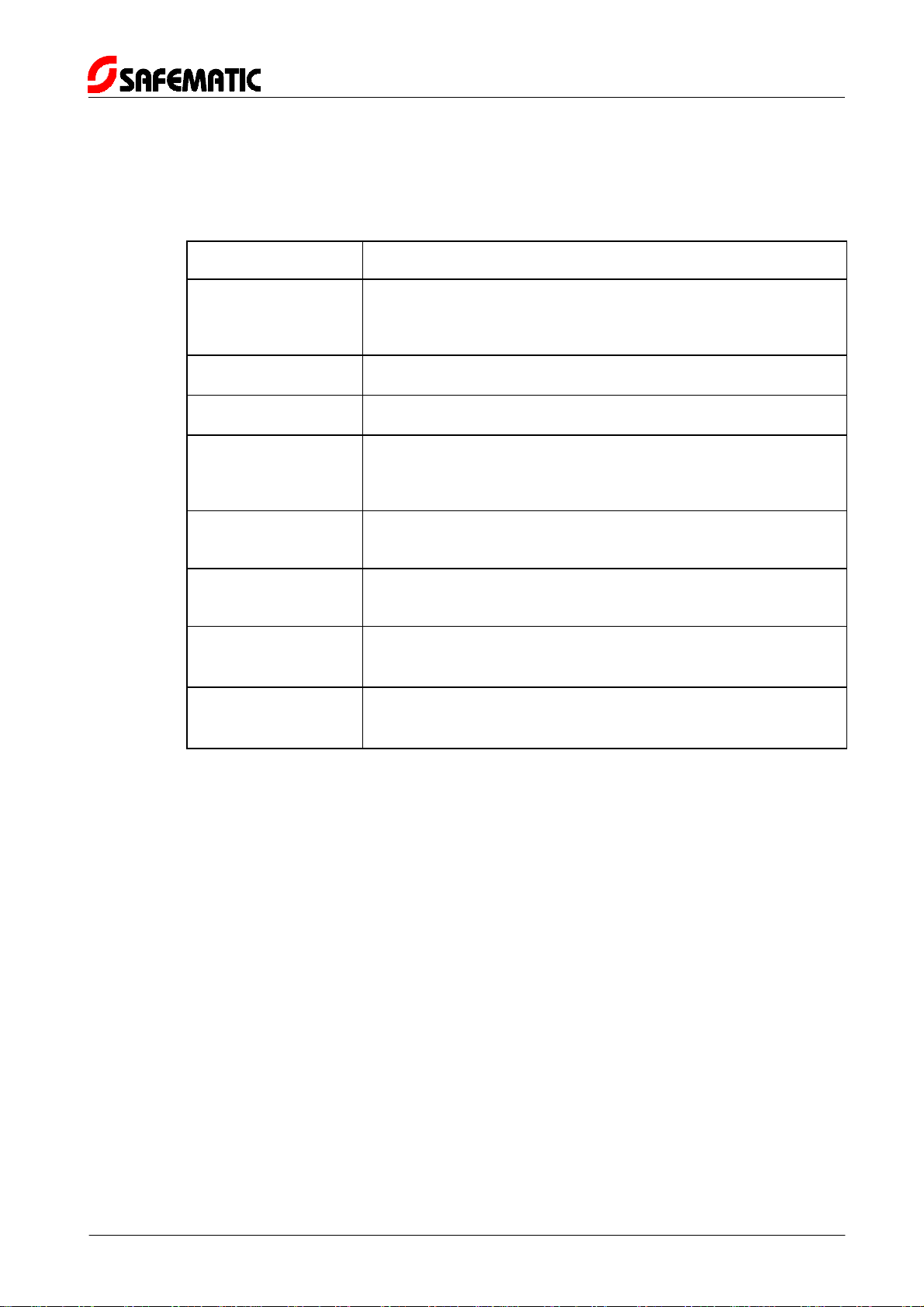

Pressure switch operation

In pressure switch operation, status of the line pressure switches can be displayed with

Î-button. Pressing the button will display status of the line 1 pressure switch first. Code P1

and line 1 pressure switch status are displayed in turns. Pressing the button again will display

the status of line 2 pressure switch. Code P2 and the status of line 2 pressure switch are

displayed in turns. The display returns to display the phase code automatically after 4 minutes

if the buttons have not been used.

The status closed contact of pressure switch is shown with code on and status open contact

with code oF.

3.2 Power failure

The set values and program status are preserved in the memory also during power failures.

After power is back on, the operation will resume from the status it was before power failure

occurred. Possible stopped pressurization restarts for the same line. Interval time is not

counted during power failures.

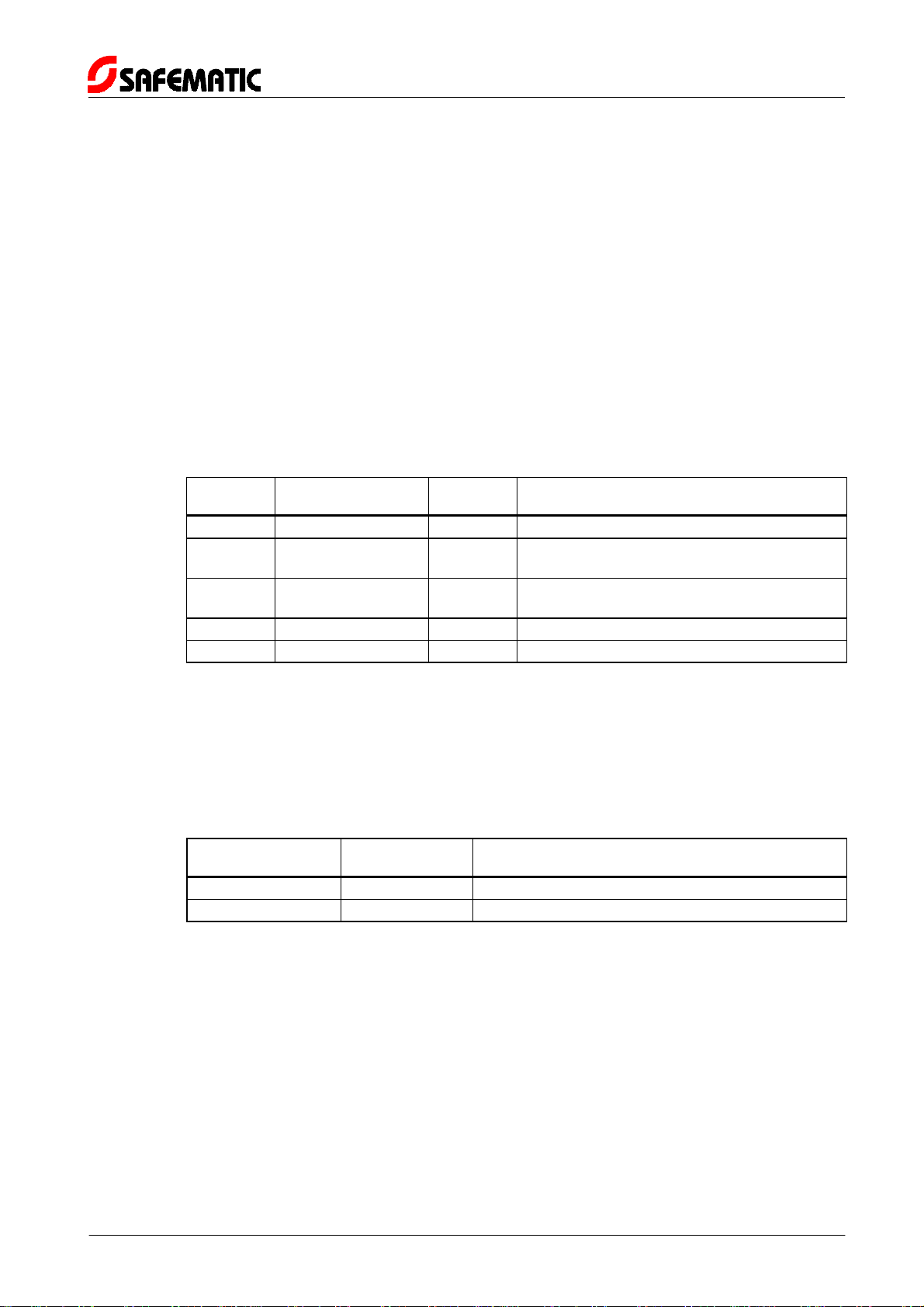

3.3 Alarms

System with one channel:

•The system is in alarm mode when the red LED-signal for line L1, line L2 or pressurization

Pis blinking.

System with two channels:

•The system is in alarm mode when the red LED-signal for channel CH1 or CH2 is lit.

•When the channel which is selected on the display is in alarm mode, the red LED-signal for

line L1, line L2 or pressurization Pis blinking.

3.3.1 Low level alarm

The channel triggers a low level alarm, stops pressurization and goes into alarm mode, if the

lubricant barrel is empty. This means that the barrel low level switch is closed. Code AGr is

blinking on the display and the red LED-signal Pfor pressurization is blinking. The same line

will be pressurized again, when low level switch is open and the alarm has been reset by

pressing the SET –button.

3.3.2 Pressure alarm

The channel triggers a pressure alarm and goes into alarm mode, if the line pressure is not low

enough when pressurization phase starts or if the line pressure does not rise high enough

during pressurization time.

Alarm, high pressure

If the line pressure is not low enough when pressurization phase starts, code AHP is blinking

on the display and the red LED-signal L1 or L2 of the line which has caused the alarm is

blinking.

In pressure transmitter operation, an alarm is triggered, if the line pressure is above the set

low limit when pressurization starts. The same line will be pressurized again, when pressure

level is below the low limit value and the alarm has been reset by pressing the SET -button.

In pressure switch operation, an alarm is triggered, if the pressure switch is closed when

pressurization starts. The same line will be pressurized again, when pressure switch opens and

the alarm has been reset by pressing the SET –button.