Page 1/ 23

TABLE OF CONTENT

1. INTRODUCTION ......................................................................................... 3

2. SUBJECT .............................................................................................. 3

3. DEVICE INTENDED USE .................................................................................. 3

3.1 APPLICATION ....................................................................................... 3

3.2 FIRE RESISTANCE ................................................................................... 3

3.3 EXECUTION VERSIONS ................................................................................ 3

3.4 DIMENSION TYPE SERIES ............................................................................. 4

4. DESIGN AND OPERATING PRINCIPLE ....................................................................... 4

4.1 DESIGN ............................................................................................ 4

4.2 FUNCTION .......................................................................................... 4

4.3 TRIGGER CONTROL GEARS ............................................................................. 5

4.4 BASIC DIMENSIONS .................................................................................. 6

5. DEVICE IDENTIFICATION ................................................................................ 6

6. DEVICE ASSEMBLY ...................................................................................... 6

6.1 PRE-ASSEMBLY INSPECTION ........................................................................... 7

6.2 INSTALLATION OPENING .............................................................................. 7

6.3 EMBEDDING / FIXING THE DAMPER ..................................................................... 7

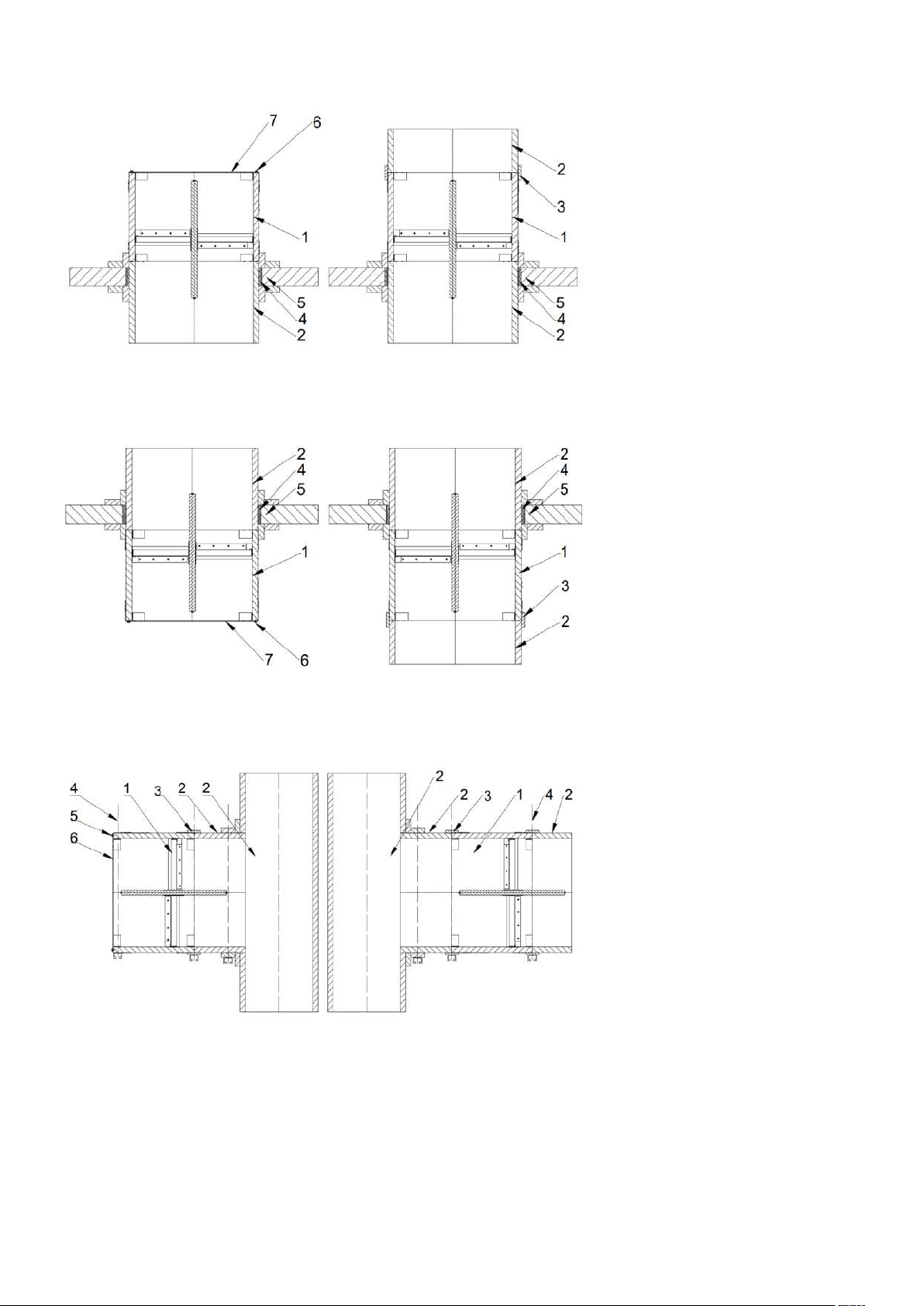

6.3.01 INSTALLATION OF DAMPER IN PANEL WALLS ........................................................ 8

6.3.02 INSTALLATION OF DAMPER IN SOLID WALLS ........................................................ 8

6.3.03 INSTALLATION OF DAMPER IN RIGID FLOOR –ABOVE THE RIGID FLOOR ................................ 9

6.3.04 INSTALLATION OF DAMPER IN RIGID FLOOR –BELOW THE RIGID FLOOR ................................ 9

6.3.05 INSTALLATION OF THE DAMPER ON HORISONTAL DUCTS ............................................... 9

6.3.06 INSTALLATION OF THE DAMPER ON VERTICAL DUCTS ................................................ 10

6.3.07 INSTALLATION OF THE DAMPER ON VERTICAL DUCTS 2 .............................................. 10

6.3.08 CONNECTION OF A MULTI-ZONE FIREPROOF DUCT, E.G. MADE OF FIRE RATED BOARDS................... 11

6.3.09 CONNECTION OF A SINGLE COMPARTMENT FIREPROOF DUCT, E.G. MADE OF METAL SHEETS................ 11

6.3.10 INSPECTION ACCESS ........................................................................... 12

6.3.11 RB CONNECTION SUBFRAME ...................................................................... 12

6.3.12 MWB SYSTEM GRILLE ........................................................................... 13

6.3.13 INTRODUCTION OF ELECTRIC CABLES FOR ELECTRIC POWER SUPPLY OF THE ACTUATOR................... 14

6.4 ACTUATORS ........................................................................................ 14

6.4.01 TYPES OF ELECTRIC ACTUATORS ................................................................. 14

6.4.02 TECHNICAL SPECIFICATIONS OF ELECTICAL ACTUATORS ............................................. 14

6.6.01 CONNECTION DIAGRAMS OF ELECTRICAL ACTUATORS ................................................. 17

6.7 RST/KW1 TRIGGER CONTROL GEAR ..................................................................... 19

6.8 INDEPENDENT LIMIT SWITCHES –RST VERSION......................................................... 21

6.8.01 TECHNICAL SPECIFICATIONS OF THE WK1 AND WK2 LIMIT SWITCHES .................................. 21

6.8.02 ELECTRICAL CONNECTIONS DIAGRAM OF WK1 AND WK2 LIMIT SWITCHES ................................ 21

7. TRANSPORT AND STORAGE CONDITIONS .................................................................... 21

8. MAINTENANCE AND SERVICING ........................................................................... 21

9. WARRANTY TERMS AND CONDITIONS ....................................................................... 22