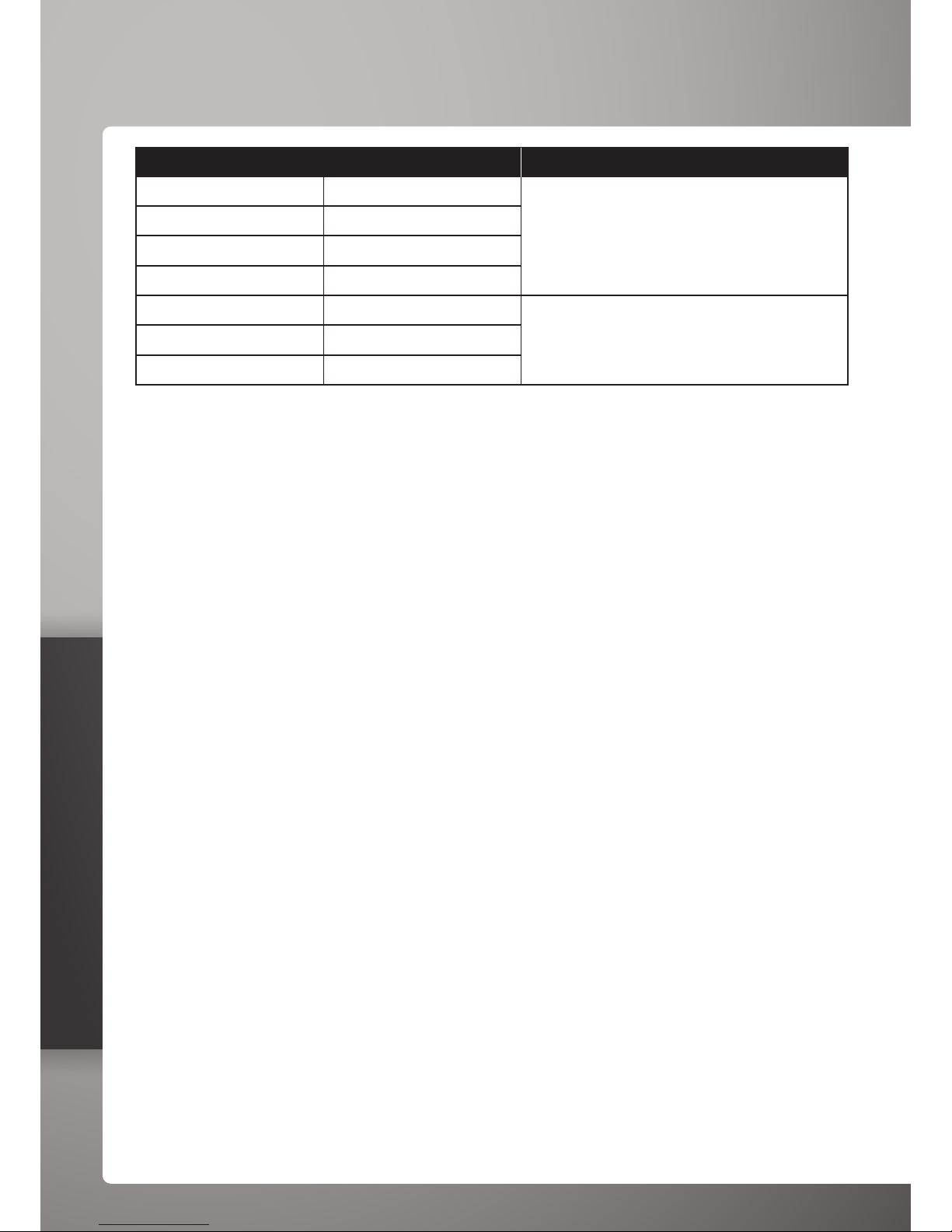

Recommended Influent Water Characteristic Notes

System Pressure

Temperature

pH range

Turbidity

Hardness (CaCO3)

Iron (Fe)

Chlorine (Cl2)

40 - 100 psi (2.8 - 7kgf/cm2)

40 - 100 °F (4 - 38 °C)

5.0 - 10.0

< 10 Net Turbidity (NTU)

< 300 ppm

0 - 1 ppm

0 - 3 ppm (0 - 3 mg/L)

1. The reverse osmosis membrane used in these systems

may be damaged by chlorine. These systems include

activated carbon filters which protect the membranes

by reducing chlorine. Influent chlorine should not

exceed 3 mg/L

2. Additional information on factors that affect RO

performance can be found in the "Performance &

Technical Information" section.

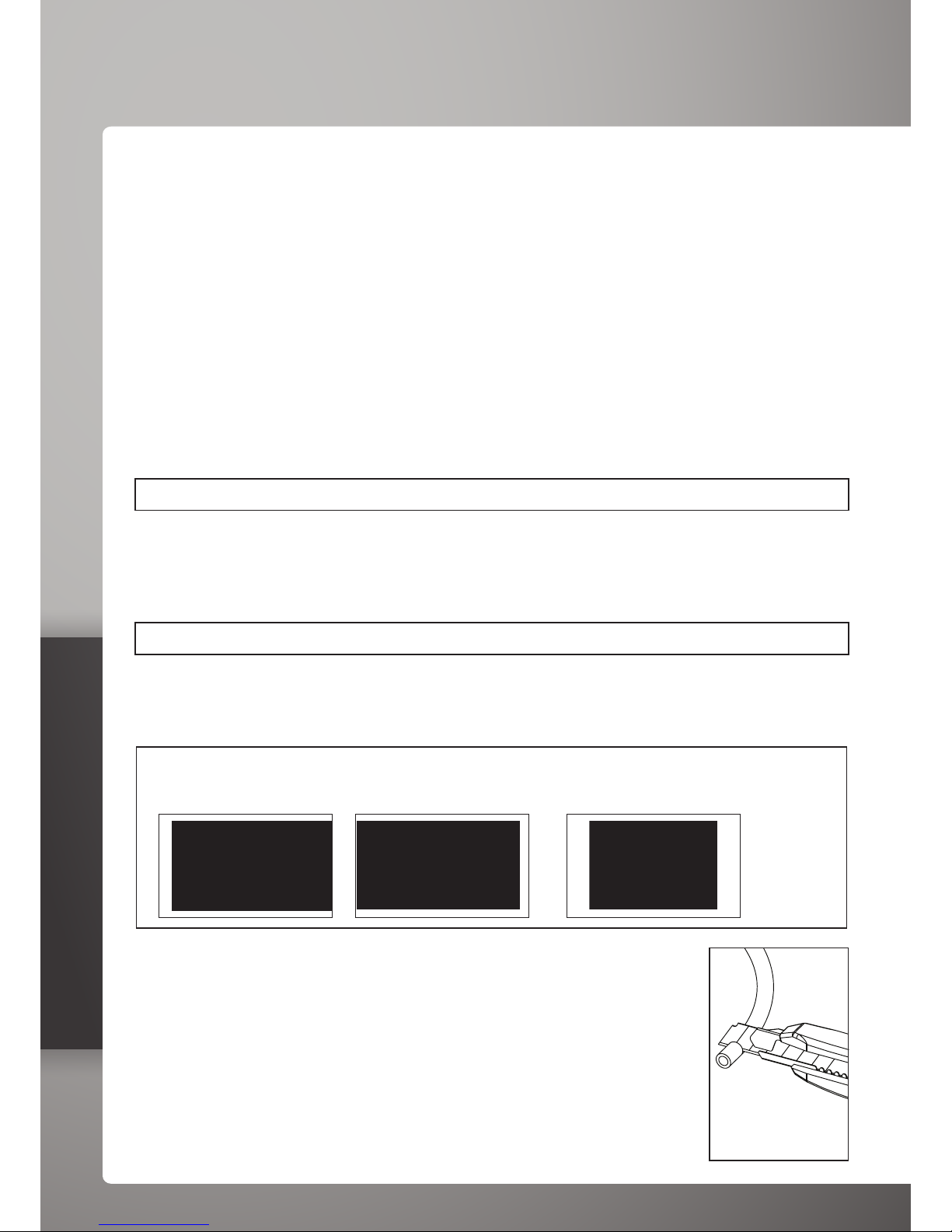

Arsenic Facts

Arsenic (abbreviated As) is found naturally in some well water. Arsenic in water has no color, taste, or odor. It

must be measured by a laboratory test. Public water utilities must have their water tested for arsenic. You can

get the results from your water utility. If you have your own well, you can have the water tested. The local health

department or the state environmental health agency can provide a list of certified labs. The cost is typically

$15 to $30. Information about arsenic in water can be found on the Internet at the U. S. Environmental Protection

Agency website: www.epa.gov/safewater/arsenic.html. There are two forms of arsenic: pentavalent arsenic

(also called As(V), As(+5), and arsenate) and trivalent arsenic (also called As(III), As(+3), and arsenite). In well

water, arsenic may be pentavalent, trivalent, or a combination of both. Special sampling procedures are needed

for a lab to determine what type and how much of each type of arsenic is in the water. Check with the labs in

your area to see if they can provide this type of service. Reverse osmosis (RO) water treatment systems do not

remove trivalent arsenic from water very well. RO systems are very effective at removing pentavalent arsenic.

A free chlorine residual will rapidly convert trivalent arsenic to pentavalent arsenic. Other water treatment

chemicals such as ozone and potassium permanganate will also change trivalent arsenic to pentavalent arsenic.

A combined chlorine residual (also called chloramine) may not convert all the trivalent arsenic. If you get your

water from a public water utility, contact the utility to find out if free chlorine or combined chlorine is used in the

water system. The QCRO4V-50 system is designed to remove pentavalent arsenic. It will not convert trivalent

arsenic to pentavalent arsenic. The system was tested in a lab. Under testing conditions, the system reduced

[0.30 mg/L (ppm) or 0.050 mg/L (ppm)] pentavalent arsenic to 0.010 mg/L (ppm) (the USEPA standard for

drinking water) or less. The performance of the system may be different at your installation. Have the treated

water tested for arsenic to check whether the system is working properly. The RO component of the QCRO4V-50

system must be replaced every three (3) years to ensure that the system will continue to remove pentavalent

arsenic. The component identification and locations where you can purchase the component listed in this

installation/operation manual.

IInstallation & Maintenance Guide 4