Precautions, Requirements & Exclusions

The integrity of Personal Fall Arrest Systems is only ensured if the user wears the

recommended personal protective equipment (PPE). This should be certified and marked in

accordance with the relevant national standard. Using the wrong PPE or SRLs/lanyards of

incorrect length can result in injury or death. Each System installed should be supplied with

specifications of a full body harness, lanyards, and shock absorbing device. See the System

Data Boxes on the System drawings for this specification. The following precautions,

requirements and exclusions apply to the fall protection equipment provided by Hy‐Safe

Technology:

•A recorded inspection must be conducted at least once a year by SAFEWAZE™ or a

Manufacturer’s Certified Installer.

•The systems must not be used for lifting.

•Do not use the systems for equipment or material tie back.

•Never exceed the recommended number of users on the systems (see the System Data Boxes on

the system drawings, or the System Tags attached to the systems).

•Never attempt to repair, tamper with or change the systems.

•Do not use the systems if they appear to be damaged or appear to have parts missing.

•Fall protection equipment should not be used outside of its limitations, nor shall it be used for any

other purpose than that intended.

•Each user should weigh no more than the maximum rated load for the energy absorbing lanyard/

SRL. The lanyard shall be capable of limiting the fall arrest load to less than 1800 lbs., and the

SRL shall be capable of limiting the fall arrest load to less than 900 lbs., per OSHA and ANSI

regulations.

•DO NOT attempt to clean the systems with aggressive cleaning chemicals and abrasive products.

•DO NOT use external fall protection systems in the event of an electrical storm.

•Only personnel trained to work at height and in the correct operation of the systems should be

permitted to use them.

•In the unlikely event that a fall does occur, the affected system(s) should not be used until they

have been inspected by SAFEWAZE™ or a Manufacturer’s Certified Installer.

•If a lifeline cable is damaged or kinked, do not use the lifeline system.

•Take care when using the systems around moving machinery and electrical hazards.

•Sharp edges and abrasive surfaces can cause damage to PPE. Take care when using the

systems where these conditions exist. If PPE becomes damaged it must be taken out of service.

Although the system are made from corrosion resistant materials, solutions containing acids,

alkali, or other caustic chemicals, especially at elevated temperatures, may cause damage to the

systems. When working with such chemicals, frequent inspection of the systems must be

performed.

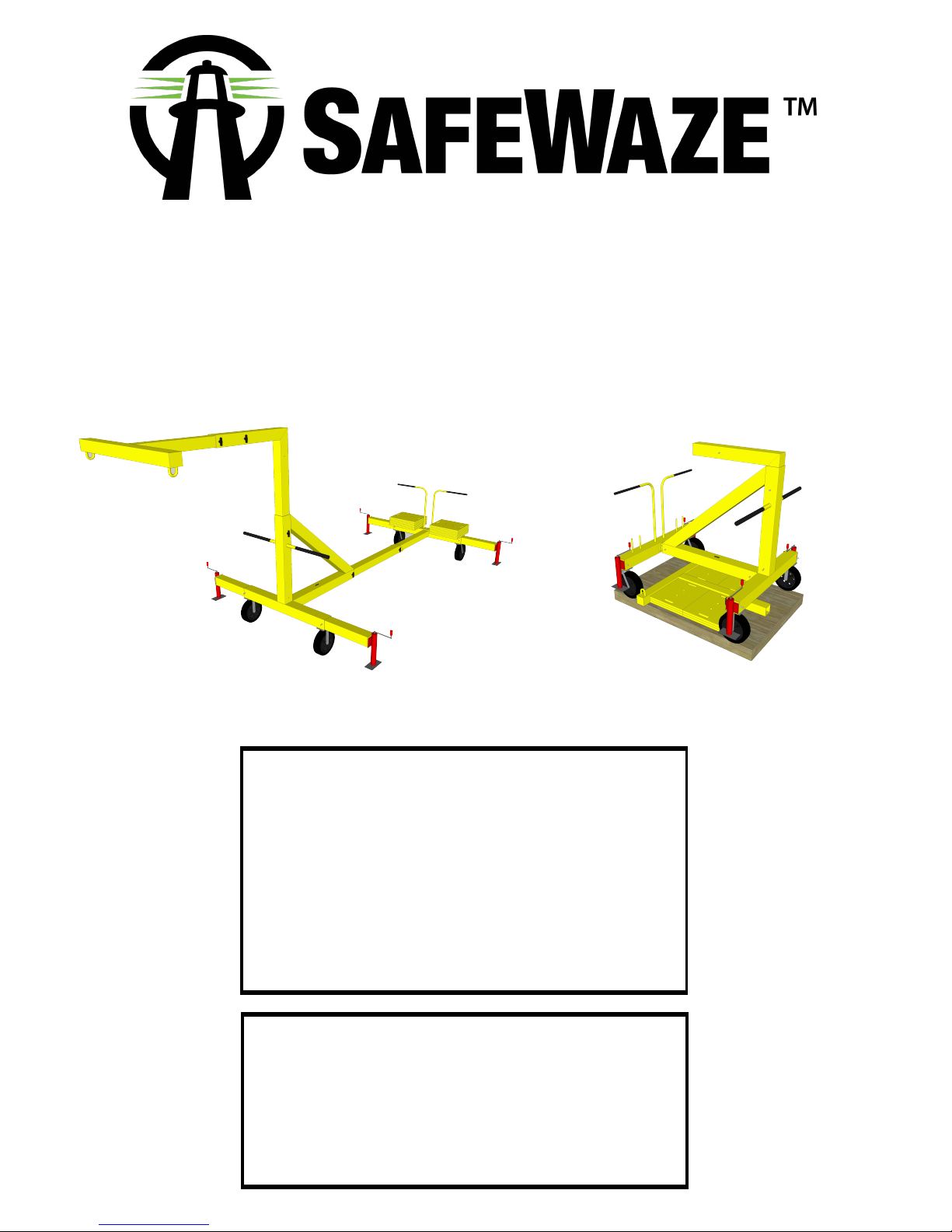

THE SYSTEM MUST BE FULLY DEPLOYED AND TELESCOPED OUT WITH SYSTEM LEVEL

AND WHEELS OFF THE GROUND COMPLETELY LIFTED BY THE LEVELING JACKS.

ALL PINS MUST BE INSERTED IN THE PROPER LOCATIONS OUTLINED IN THE SET-UP

DETAILS BELOW.