7/34 • GAFM-II-10.12

SAFEX®-FLOWMARKER-II

For best use in all fields of application of the SAFEX®-FlowMarker®Model II, it is rec-

ommended to read this instruction carefully even if one is already familiar with the

previous model.

This instruction manual is to be supplemented if necessary with the instructions of each

ancillary used, optional FlowMarker® accessory.

The safety instructions and all sections marked with the attention sign are espe-

cially important and should be given particular consideration.

The SAFEX®-FlowMarker®Model II has been considerably improved compared to its

predecessor:

The functions of the device are now controlled by a microprocessor, which

allows improved operation, equipped with more features!

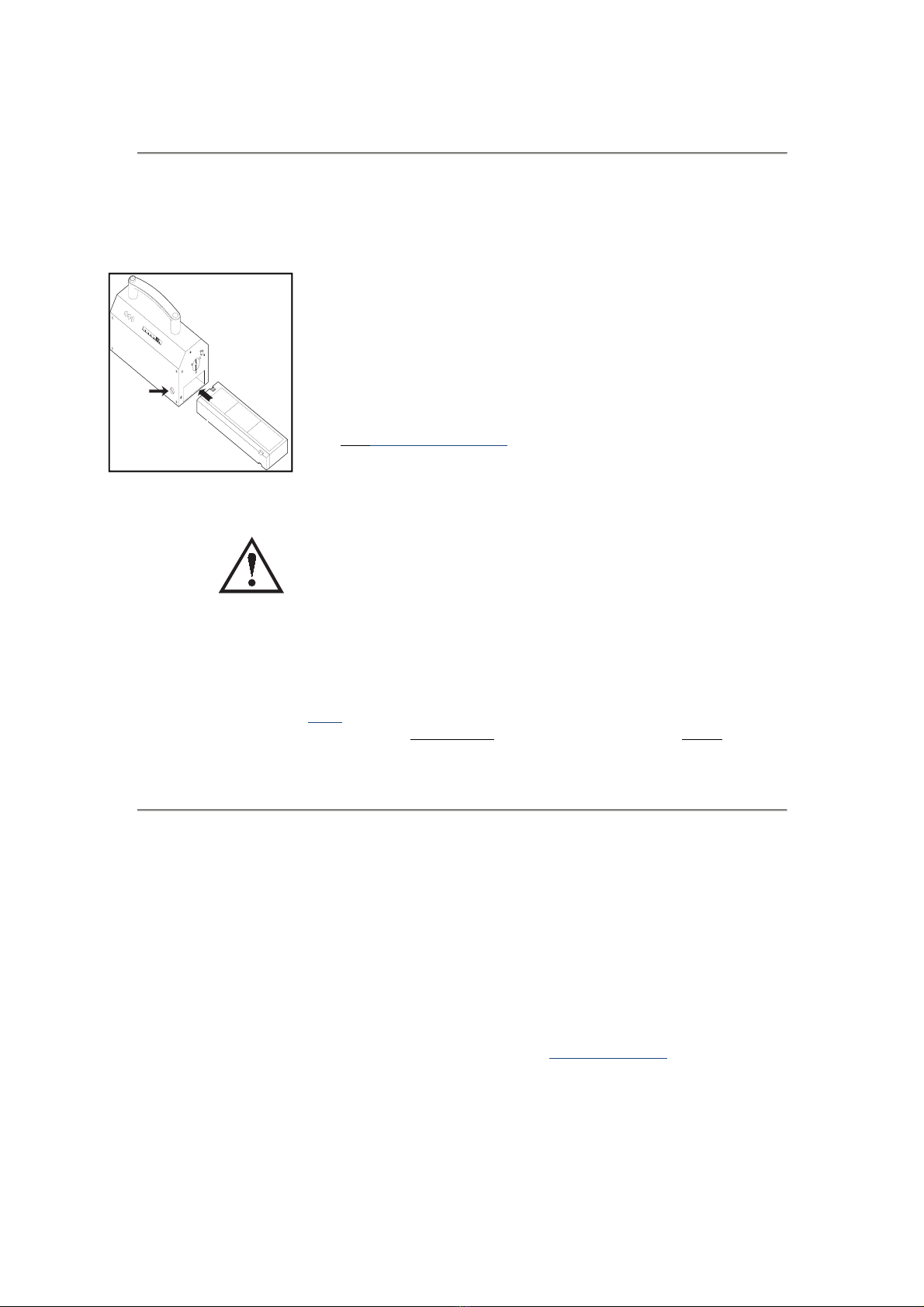

The unit now contains as standard a remote control socket for instant connec-

tion with a remote control.

The activation of the FOG FLOW will now be done by an ON/OFF Switching

(Switching function, no longer touch function). The fog flow is now turned on by a

short push onto the blue FOG-button and as well shut off by pressing the button

again, in the same way as it has to be done with the new remote control's.

Due to the new, integrated microprocessor the device automatically switches into

the so-called ENERGY-SAVING -MODE for saving some battery capacity if no fog

production is been done. It further will be switched into the so-called SLEEP

MODE when continuously not be used and finally - after a longer non-use - the unit

turns itself off completely.

The battery capacity is spared in this way, the unit will remain longer ready for use

and also a harmful deep discharge of the battery is prevented.

The SLEEP MODE ensures that the unit uses very little battery power, but it re-

mains active for remote control.

In addition to the automatic shutdown after prolonged non-use or lack of battery

power, the device is now also equipped with a manual shut-off function,with

which it can be turned off at any time completely.

In addition, the new MODEL II is optimized for new accessories.

ASYSTEM DESCRIPTION

The SAFEX®-FlowMarker®Fog Generator was especially developed for the visualization

and photographic documentation of slow and weak airflows in the fields of science and

technology. Fog is produced with the world's unique and completely harmless SAFEX®

theatrical fog fluids.

The generation of low-impulse, thermal neutral fog helps to solve even very difficult

problems of airflow visualization.

In areas with a calm airflow, even small cavities can be filled with fog. This fog, as if

flowing like water, forms a “fog lake” on the surface where even very weak airflows can

be recognized.

Furthermore, new, additional system components, such as the FM-HYDRA-TUBE SYS-

TEM©are available which makes it now possible, to insert the fog for example via hoses

MODIFICATIONES TO

PREVIOUS MODEL