INSTRUCTION MANUAL

Model HC

Reference 219 Rev 2

Page 8 of 46 06/20/2013

1.0.1 Dryer Location and Mounting Specifications (continued)

1.0.1.12 For electrical connections, refer to the electrical drawing in

Section 8. Be sure to look for any auxiliary connections, such

as remote alarm contacts, compressor interlock relay (if

needed), or analog (4-20mA) signals.

1.0.1.13 Ensure that the inlet and outlet connections to and from the

dryer are made using the correct rated fittings and piping to

meet the design conditions. For connection details, refer to the

flow schematic in Section 8.

1.0.1.14 Insulate the pipe between the compressor and dryer to

minimize heat loss.

1.0.1.15 Do not hydrostatically test the pressure vessels. All HC dryer

pressure vessels are hydrostatically tested at 1.3x the design

pressure, per ASME code, after fabrication and before

assembly of the dryer.

1.0.1.16 It is recommended that the common alarm relay, located in the

dryer control panel, be connected to the control room or

operator station, so that an immediate response to the dryer

alarm may be given when required.

1.0.1.17 If the equipment is installed in a high traffic area, protective

barriers may be required to prevent possible damage of

equipment and to prevent contact with hot surfaces.

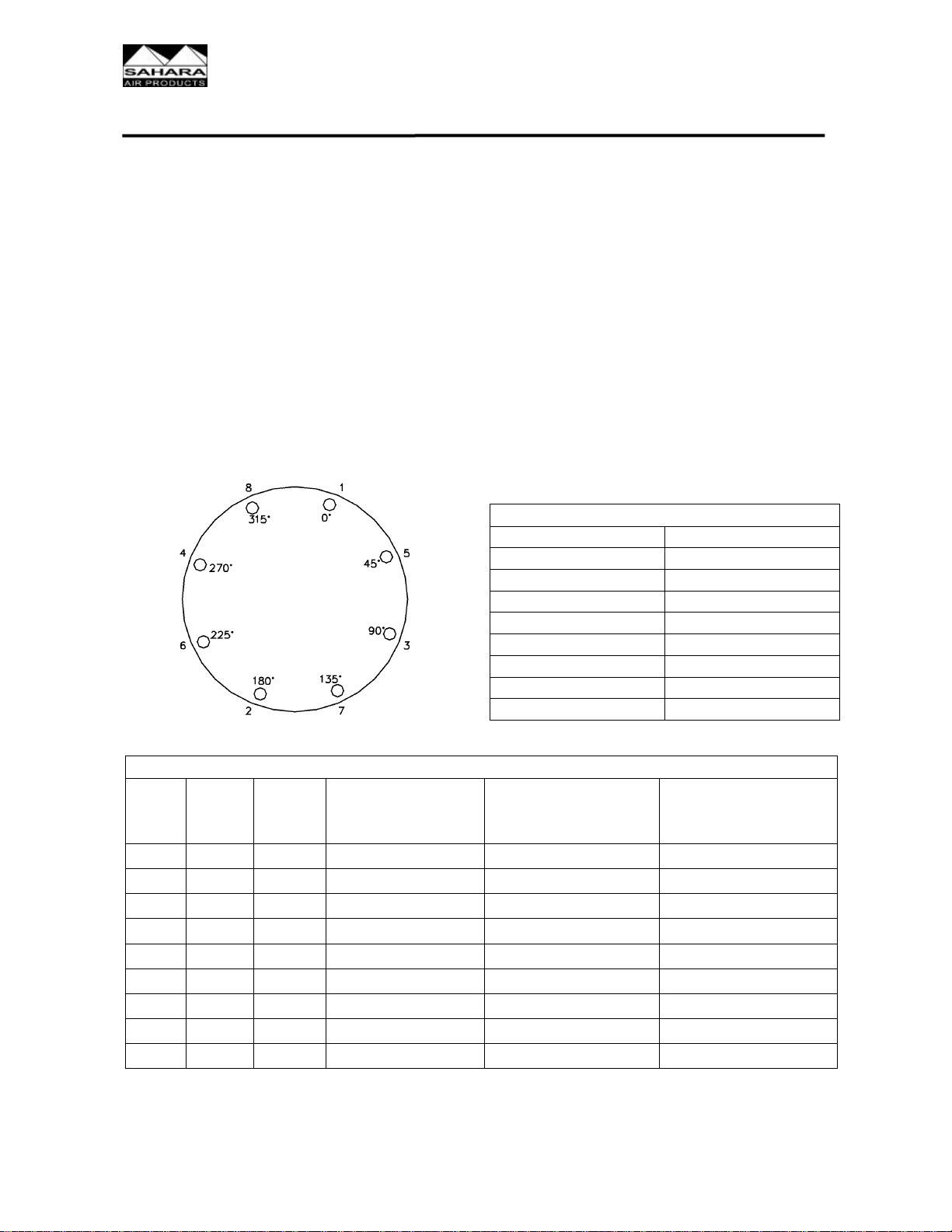

1.0.2 Preventative Maintenance Prior to Start-up

1.0.2.1 All air dryers are tested at the factory for leak-tight joints and

tightness of bolts; however, during shipment, some bolts may

vibrate loose. We have no control over the handling our

compressed air systems receive after leaving our factory. To

prevent costly problems at start-up and operation, all bolts

should be checked for tightness prior to system pressurization.

This will assure gasket life as well as prevent possible gasket

blowout. Gasket joints should be bubble tested after four or

five complete cycles of the dryer, to ensure gaskets are

sealed. Any loose joints will need to be re-tightened and re-

tested for leaks. Following is a comprehensive procedure for

tightening all pressurized gasketed joints. If the dryer includes

manual butterfly valves, valves must be totally closed before

re-torquing bolts.