2

Metal Detector

METARIDDER

<Cautions>

The machine is assembled with precision. Do not expose it to excessive

vibrations and/or mechanical impacts.

Install the machine on a level floor without a vibration.

Avoid using the machine under a high temperature and humidity.

The operating temperature for the machine is 5Cto 40C. * Dew formation must be

avoided.

With high-temperature type LV1, the operating ambient temperature shall be 5C

to 45C.

If the machine is not going to be used for a prolonged period, always turn OFF

the main circuit breaker and the power supply.

If a plug is provided, pull out the plug from the power outlet.

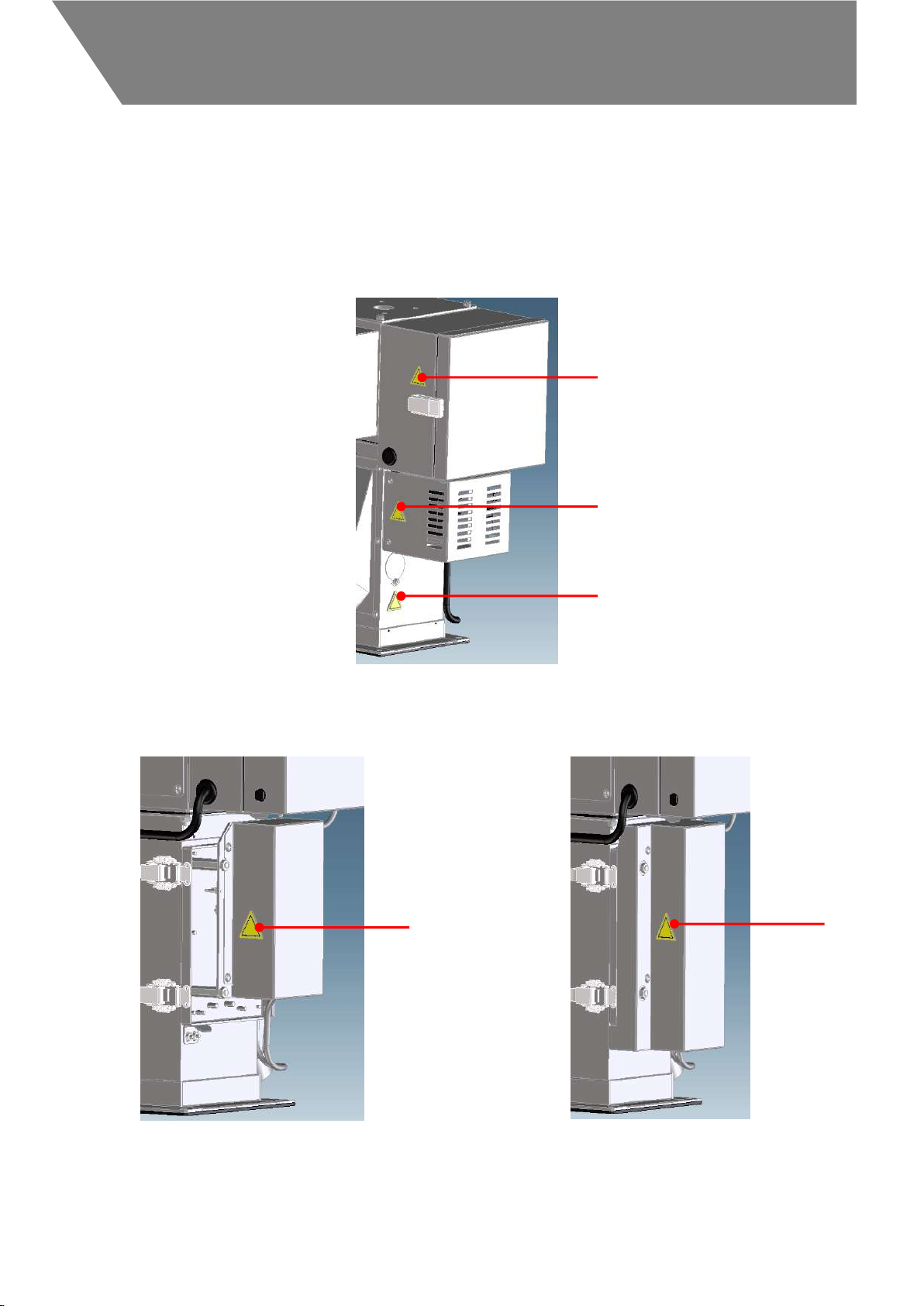

Notes on the Operation

[1] The machine has been adjusted to detect and remove metal pieces contained in virgin plastic

pellets and pulverized plastic pellets. To use this equipment for any material other than plastic

pellets or for other purposes, consult us.

[2] Install the machine on a level so that the materials subject to inspection will fall freely through the

metal detector unit.

[3] Although sufficient care is taken to make the machine resists vibrations and environmental

conditions, the user may be requested to adjust the sensitivity to a weaker level depending on the

environment to avoid malfunctions due to vibrations and/or noise. If such an adjustment is

required, note that metal detection as described in the specifications may not be possible.

[4] Always clean the machine before changing the materials to be loaded. Materials remaining in the

machine may contaminate the material to be loaded next. (Flushing the machine with water is

strictly prohibited.)

[5] The ceramic materials used for the section coming in contact with pellets within the sensor may

break due to an impact. In cleaning the machine, be extra careful not to apply impacts to the

ceramic material by poking or rubbing it with a metal rod.

[6] Do not disassemble the metal detector since it is enclosed in a metallic housing and assembled

with precision to eliminate effects of noises. Disassembling the metal detector will void the product

warranty and SAIKA may refuse to perform maintenance services thereafter.

[7] Use the machine at the rated voltage. Using it at a voltage other than the rated voltage may result

in a machine failure, damage on the machine or electric shock to the operator.

[8] Supply the power to the machine from a dedicated power supply. Supplying the power from other

devices (such as a molding machine) may cause a malfunction due to the introduction of noises.

[9] The operating temperature of the machine is 5C to 40C and the material temperature is 5C to

40C. (* Dew formation must be avoided.)

With the high-temperature type, the operating ambient temperature shall be 5C to 45C, and the

material temperature shall be 5C to 70C. (* Dew formation must be avoided.)

[10]In installing the machine, ensure to provide a grounding (Class D grounding). Otherwise,

malfunctions may occur.