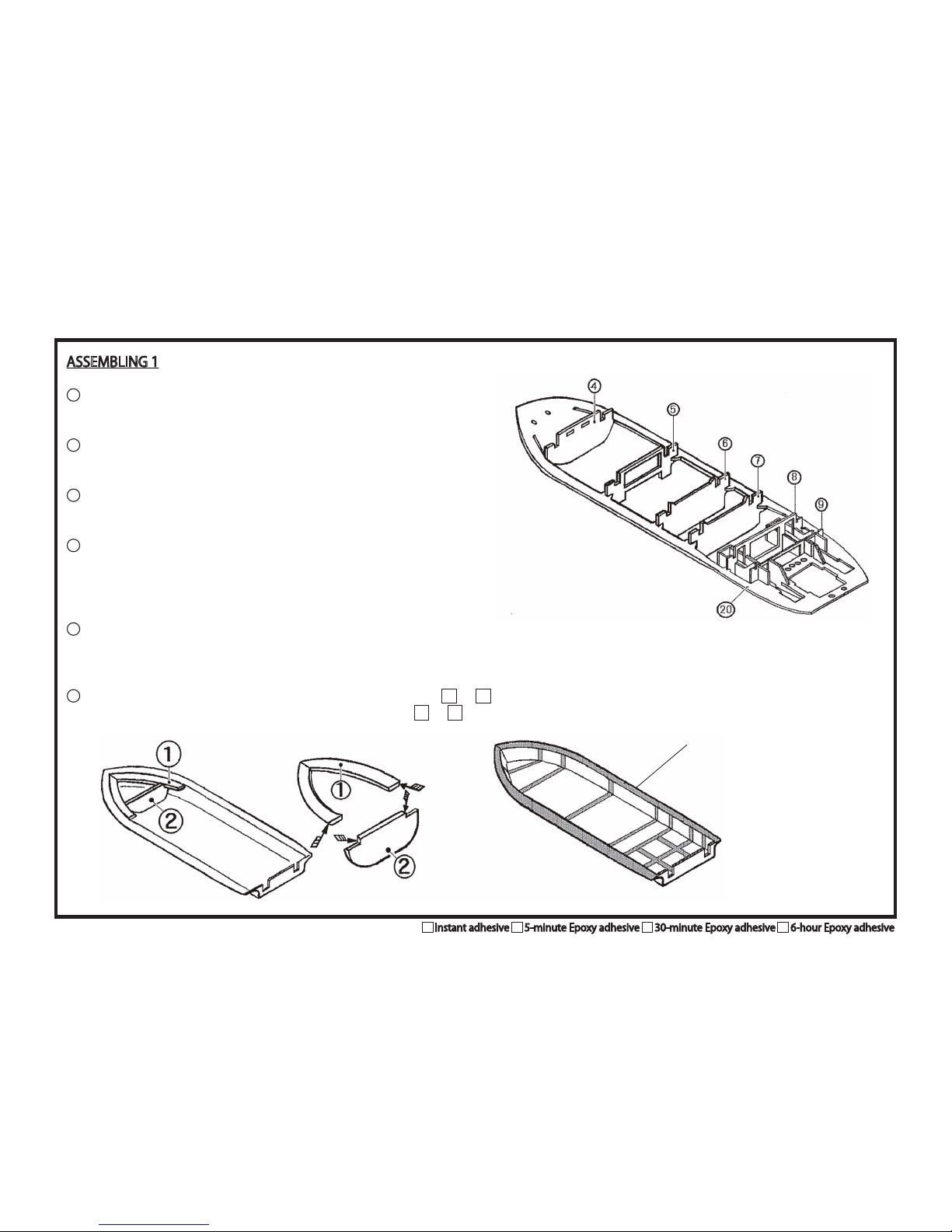

BEFOREASSEMBLING

Wewouldliketoexpressourappreciationforyourpurchasing“VICTORIA”.

Thisisashipwhichwedesignedoriginallybasedonarealpaddlesteamer.Youwillfinditselegantoutlookworthythenameof

“VICTORIA”whichisthegoddessofvictory.

ITEMSTOBEPREPAREDFORASSEMBLING

TOOLS

Handsaw(withfineteeth),Cutters(largeandsmall),Smallplane(balsaplane),borer,files(flatandround),sandpaper(#180,

#240~800),radiopliers,nippers,screwdrivers,router,pinvice,clips,hammer,rule,etc

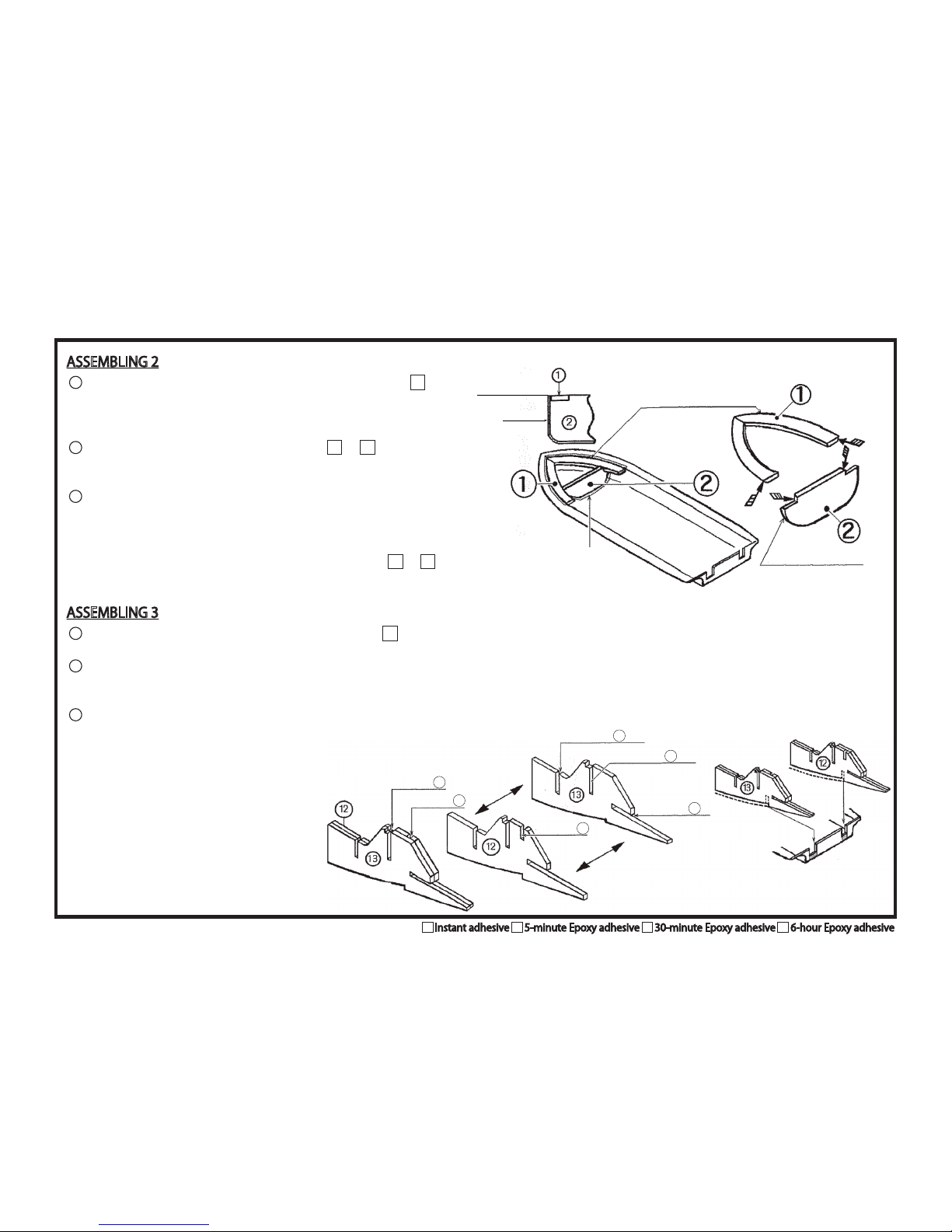

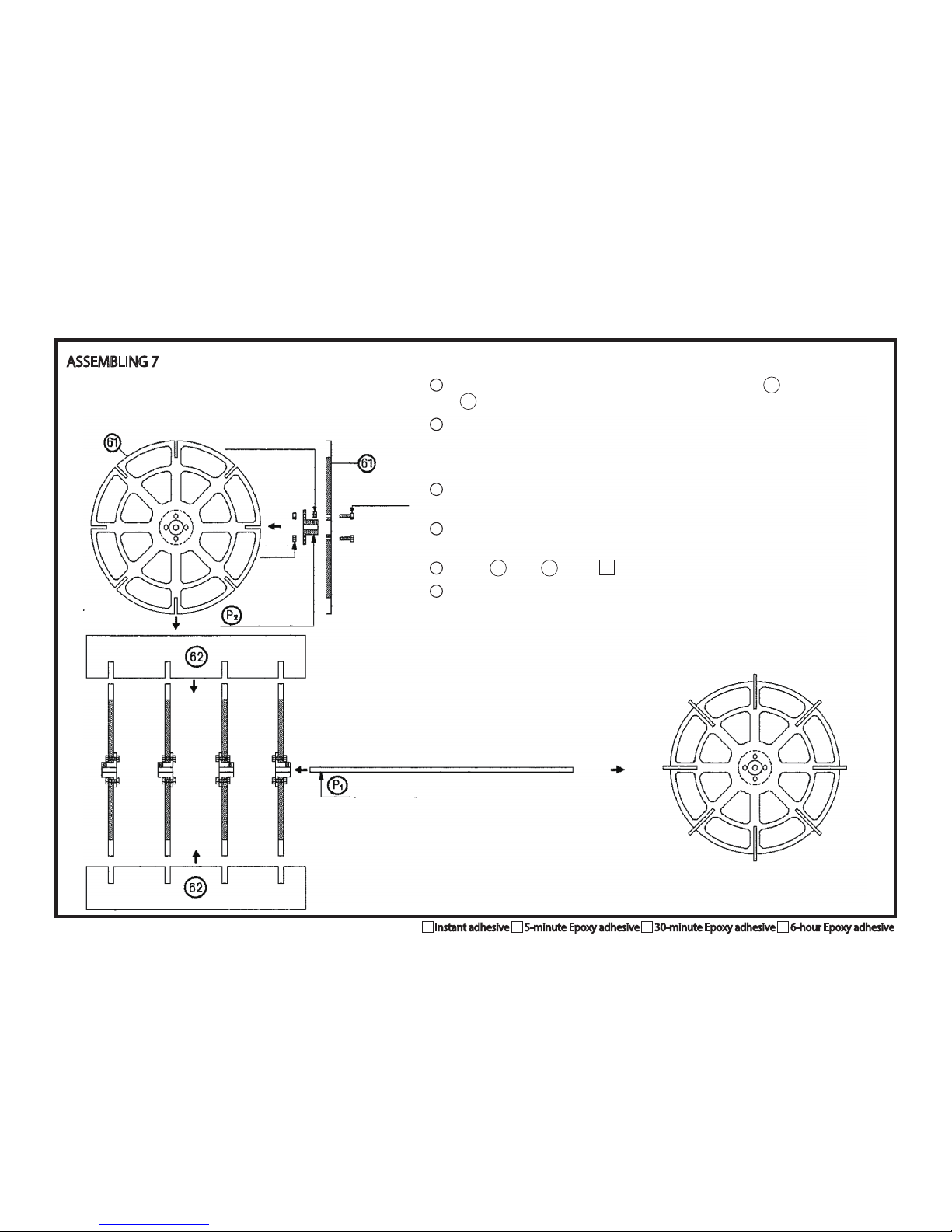

ADHESIVES

Thenumbers1,2,3,and4inthismanualindicatethefollowingadhesives(intheorderoftimerequiredforgluing):

1Instantadhesive

LowandHigh-viscositytypeseachforwoodworkingpurpose.

25-minuteEpoxyadhesive

Thisfeaturestherequiredshort-gluing,andcombinedusewiththeinstantadhesivewillreducetheworktimesignificantly

330-minuteEpoxyadhesive

46-hourEpoxyadhesive

ThisisusedforgluingtheveneerframeswithFRP.Placethemixtureofthetwoliquidsinacanandheatitwithadryeruntilit

liquefies.In2to3hours,itwillharden.

Polyesterpaste

Tomendanyundesignedhollowsorscratchesduringworking.

Paint

Alacquerorurethanesystemthatisfamiliartoyouisrecommendedforthebody.Forsmokestacksandothersmallfittings,youcan

usethestandardpaintsforplastics(Placolor)ofwhichmanykindsofcolorareavailable.Foretchingbeforepaint,sandpapersof

#240to800arerecommended.

Smallfittingsarebetterpaintedbeforegluing.Pleasebesuretoreadthesection“Paintingandfinishing”inthefollowingpage

beforeassembling.

NO1