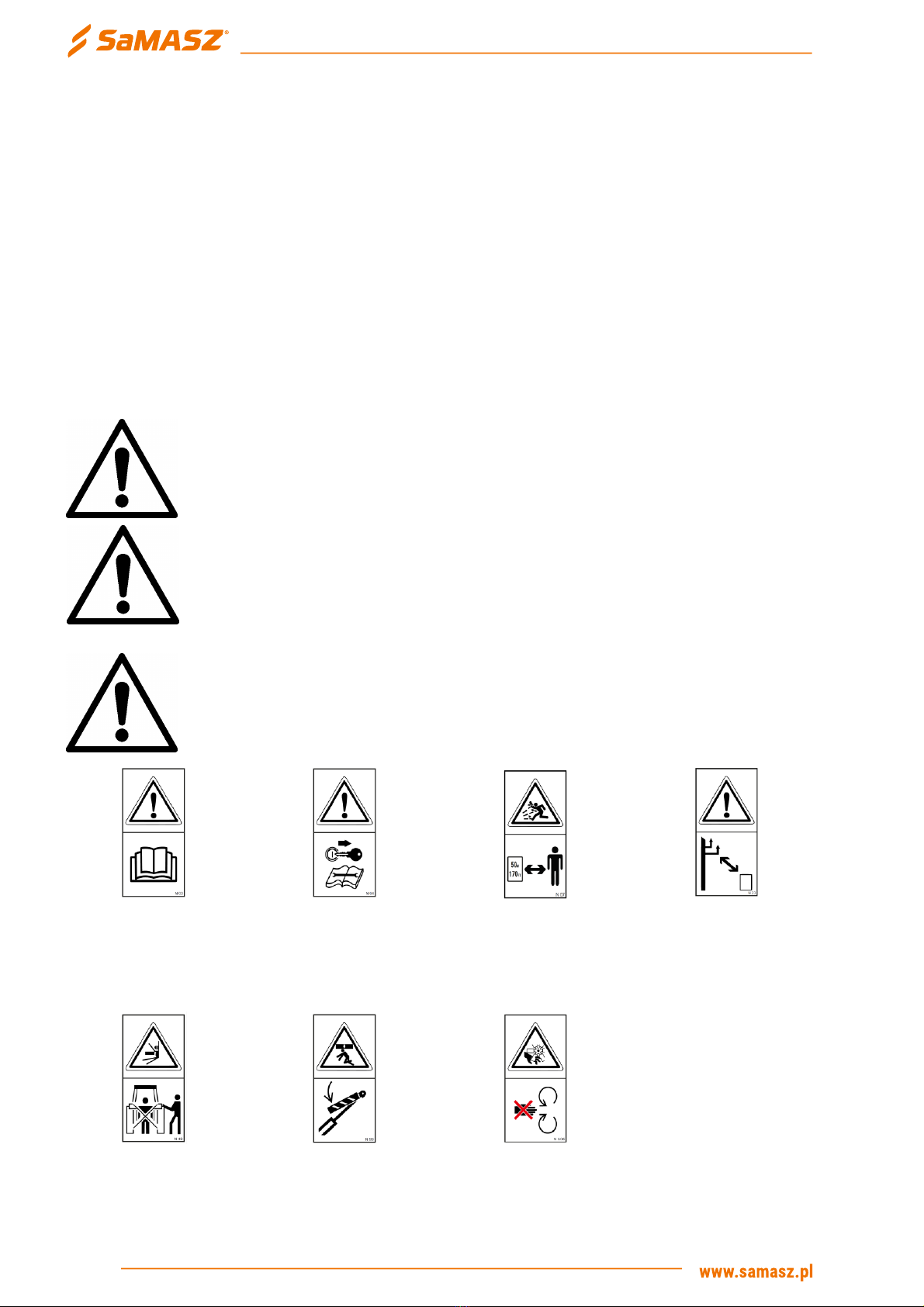

❑When connecting hydraulic hoses to the tractor's hydraulic connectors make sure, that the

hydraulics on either the tractor or the extension arm aggregate are pressure free.

❑Before connecting the hydraulics reduce pressure in hoses.

Transport

❑When driving on public roads always respect the local traffic regulations concerning warning

lights.

❑Remove or partially disconnect the PTO shaft on the tractor side for the transport of the

assembly.

❑While transporting the above aggregation mount remote warning light device and warning triangle

for a slow driving vehicle.

❑During transport, always set the machine in its proper and safe transport position. See section

3.3.

❑Any modifications in the machine's position are possible only if no vehicles or unauthorized

personnel are around (children in particular).

❑Always adjust the driving speed to the road conditions.

❑Do not drive over 25 km/h (15 mph).

❑In case of damage to the hydraulic system during transport, the extension arm actuator should be

secured with a special lock (the c-rail on the actuator piston rod).

Operation

❑When operating on public roads always respect the local traffic regulations and provisions

concerning warning lights.

❑Admissible slope, on which the machine is able to operate is provided by the Manufacturer.

Angular value for safe operation on slope is 8º.

❑Unauthorised personnel and animals should keep away from the grinder for a safe distance, which

is at least 10 m from the machine. Keep particular attention when operating near roads and lanes,

where presence of unauthorized personnel is likely.

❑When operating the aggregation of arm and road shoulder cutter, make sure the tractor is always

equipped with operator's cabin.

❑When operating the aggregation of arm and grinder, make sure the tractor is always equipped with

operator's cabin.

❑Before starting the tractor, make sure that all drives are disconnected and control levers for

hydraulics are in neutral position.

❑Before moving, make sure whether there are no unauthorised personnel directly nearby the

machine, give an acoustic signal.

❑Never leave the tractor’s engine running without any supervision. Before leaving the tractor, turn

the drive off, set the aggregation of tractor and extension arm and the tree stump grinder in a

standstill position and remove the ignition key.

❑For any break in the machine operation, disconnect the drive.

❑The road shoulder cutter should be operated at 540 rpm of the PTO (applies to SaMASZ extension

arms).

❑All machine movements must be performed only from the operator’s seat. Do not control the

machine outside of the tractor cab.

❑The operating speed of the extension arm-cutter assembly should be adjusted to the operating

conditions, such as: the amount of removed material, its density, terrain unevenness.