Index revision : 3

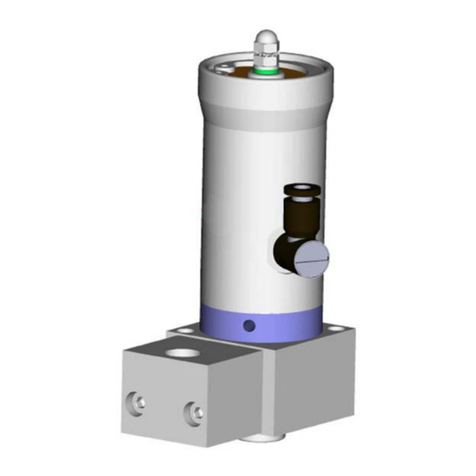

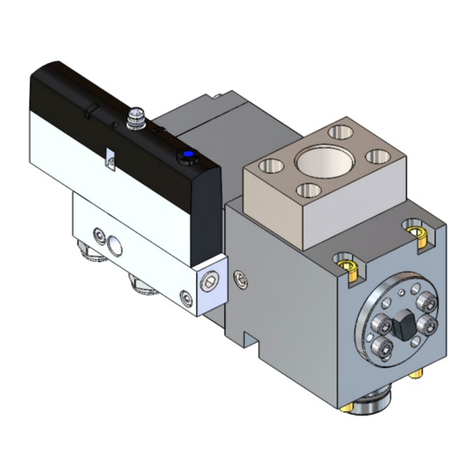

Inobox

Control module

1. Health and safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

1.1. Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2. Precautions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

3. Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

3.1. Mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3. Air compressed quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. Operating principle of the Inobox - - - - - - - - - - - - - - - - - - - - - - - 11

4.1. Pneumatic Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2. Electrical and Signal Connections . . . . . . . . . . . . . . . . . . . 12

4.3. Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4. Functions available from the Inobox control module . . . 13

5. Use of the various menus of the Inobox control module - - - - - - - 14

5.1. Start screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2. Screen 1: Operating Modes Screen . . . . . . . . . . . . . . . . . . 16

5.2.1. Choice of presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3. Screen 1: Custom mode screen . . . . . . . . . . . . . . . . . . . . . 17

5.4. Screen 2: Setting of electrode supply air and fluidizing air 18

5.5. Screen 3: Counter Alarm Screen . . . . . . . . . . . . . . . . . . . . . 19

5.6. Screen 4: Cleaning screen . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.7. Screen 5: Ecran Présence Défauts . . . . . . . . . . . . . . . . . . . 21

5.8. Parameter setting screens . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.8.1. Access to the parameter setting screens. . . . . . . . . . . . . . . . 22

5.8.2. Password Input Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.8.3. Parameter setting screen 1: Equipment operating time . . . 23

5.8.4. Parameter setting screen 2: Fault History Screen . . . . . . . . . 24

5.8.5. Parameter setting screen 3: Active cleaning phase . . . . . . 25

5.8.6. Parameter setting screen 4: Parameter setting Locking /

Unlocking setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.8.7. Parameter setting screen 5: Time Delays . . . . . . . . . . . . . . . . 27

5.8.8. Parameter setting screen: Contrast and Communication

Configuration (a CAN link is used) . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8.9. Access code modification screen for parameter setting

screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.9. Standby Screen / Factory Reset screen . . . . . . . . . . . . . . . 30

6. Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

6.1. CAN Inputs / Outputs connector . . . . . . . . . . . . . . . . . . . . 31

6.2. Vib / Smoke connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3. 100 / 240 VAC power supply connector . . . . . . . . . . . . . . 31