Index revision : I - November 2018 9 6243

6.3. Reassembly

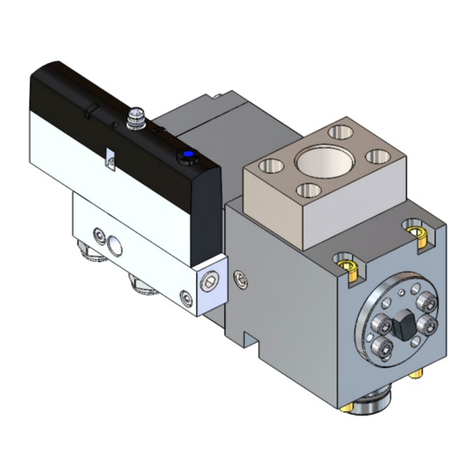

6.3.1. Reassembly of the pneumovalves all types except the pneumovalves isocyanate

In reverse order, observing the following precautions:

1 Install in the stuffing box body: the conical seal, the seal cartridge and the metallic ring

respecting their assembling order.

2 Compress the stuffing box spring 9(by pushing the parts forming the pneumovalve body

by hand) while screwing the needle 11 (or 16).

3 Screw both assembly screws simultaneously and tighten them firmly.

Note 1: It is normal to find a regular, ring-shaped notch on the cone of the needle. This area of

caulking is useful for providing a good seal. However, if it is irregular or has stripes cut into it, the

needle may no longer be sealed and needs to be replaced.

Note 2: An oil-resistant cyanoacrylate sealant (Loctite) is used to produce the seal between the

piston 6 and the shaft 8 (or 14). Only dismantle these parts if absolutely necessary, and renew

this seal when refitting.

Note 3: Before replacing the gaskets 3 or the piston seal 7, soak the replacement parts with a

few drops of pure vaseline oil.

Note 4: If the gaskets, piston seal or needle are changed, "break in" the refitted pneumovalve

by carrying out 500 cycles without product so that:

• The needle is caulked,

• The gaskets are compacted and sit correctly,

• The piston seal is worn in.

6.3.2. Reassembly of the isocyanate pneumovalves

Assembling and Caulking of the biconical sealing ring (Ref.: 441117)

•Step 1: Soak the rings at least 30 minutes in vaseline oil, leave a ring vaseline oil and put it

in the body of piston (ref.: 434987),

•Step 2: Put in place above the spring bushing (Ref.:449093) and to caulk slightly on the

spring bushing (Ref.:449093) (in general a small blow is enough, if not a part of the ring will

pass side piston.)

WARNING : The caulking of the ring will be made without the axis of piston in order to obtain a

light tightening of the ring which will ensure the sealing on the axis.

•Step 3: In the body of stuffing box (Ref.:1312749), install the tapered seal (Ref.:749986) and

the equipped seal cartridge (Ref.:749987) (take care to the direction of assembling of the

equipped seal cartridge).

•Step 4: Put in place the drain washer (Ref.:749985) then the spring (Ref.:449095).

•Step 5: Secure the body of stuffing box on the body of pneumovanne with the two screws

(F/90 HC 4x20 ref.: X4EVSF123).

Assembly of the axis of the piston in the body

•Step 6: Block the axis of piston side "fir tree" on a small chuck of drilling machine positioned

vertically (not to twist the axis), introduce the pneumovalve side stuffing box, and screw it

on the level of the sealing ring (ref.: 441117 (to avoid withdrawing it).

•Step 7:Push completely the pneumovalve until it stops on the chuck.

•Step 8: Clean the axis (threading recover a little trimming and vaseline).Screw and block

the nut (ref.: X4KEHU003) completely.

Note: the axis should not turn in the chuck.