6 EB 7500 EN

Application

2 Application

The Series420 Control System is used in au-

tomation applications in process engineering

and industrial plants. It can be used for ap-

plications with P, PI, PID, and PD controls, for

control loops with control mode changeover

or signal limitation, for xed set point, ratio,

cascade, or slave control.

The output signals of a connected transmitter

or master controller are measured as pneu-

matic standardized signals between 0.2 and

1bar or, in case of i/p additional modules,

0/4 to 20mA signals.

The integrated controller modules compare

the measured variable with the set point and

issue a corresponding pneumatic control sig-

nal of 0.2 to 1bar (2 to 15psi).

The controller requires a supply pressure of

1.4bar (20psi).

3 Operation

3.1 Settings at the controller

modules

The settings for direction of action and air

delivery must be performed prior to start-up.

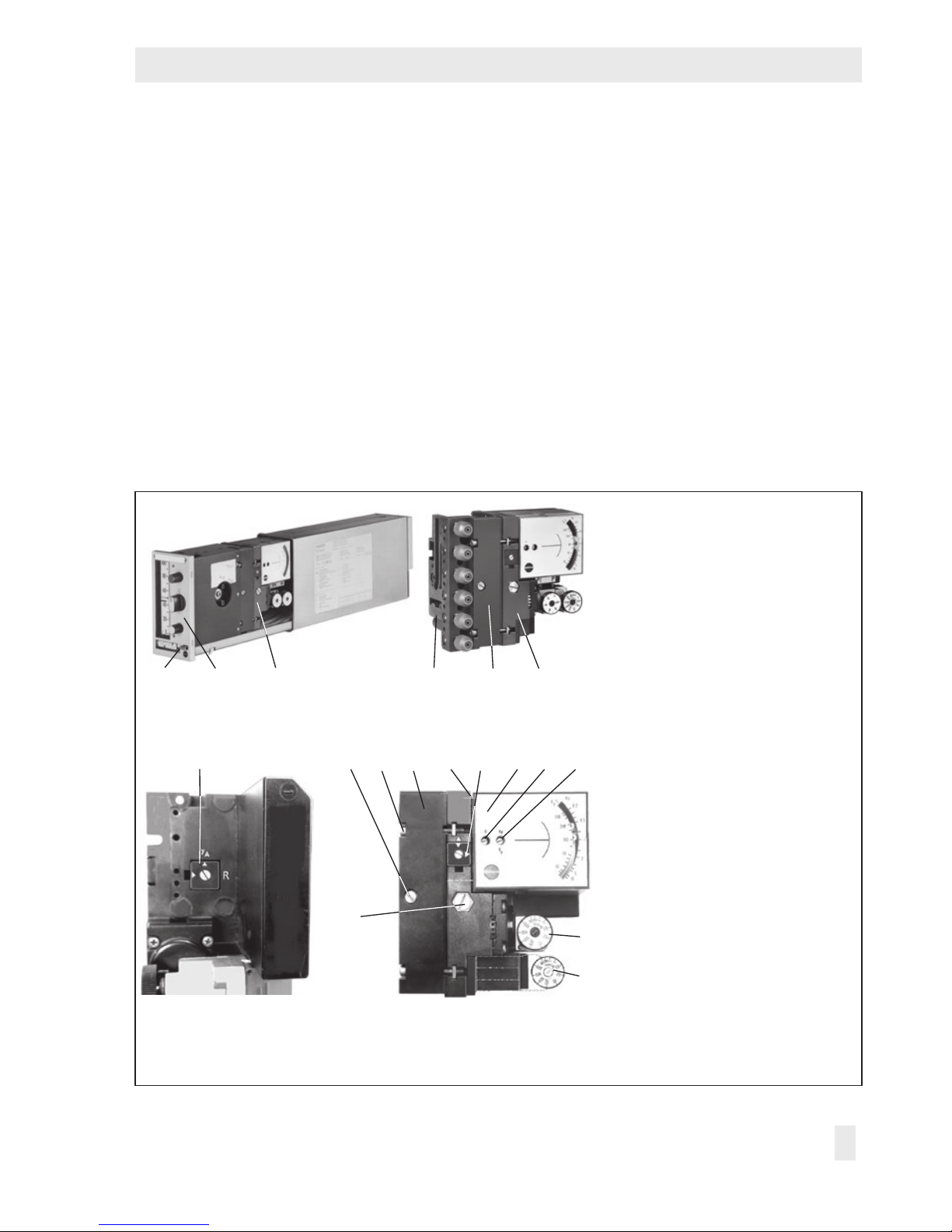

Release the lock (4 in Fig.1) on the front

panel of the compact controller and pull the

manual control station completely out of the

housing to access the controller module.

3.1.1 Direction of action

The direction of action for the control loop is

set at the turnboard A. Tshe position of its

arrow symbol according to the arrow symbol

on the controller module determines the

direction of action of the controller (Fig.1).

< > Arrow tips facing opposite directions:

Direction of action increasing/decreas-

ing

As the controlled variable x increases,

the output pressure y falls.

>> Arrow tips facing the same direction:

Direction of action increasing/increas-

ing

As the controlled variable x increases,

the output pressure y increases.

Setting or changing the direction of action:

Unscrew the screw in turnboard A and lift it

off together with the turnboard. If necessary,

lever the board at the side. Do not lose the

rubber seal.

NOTICE

!