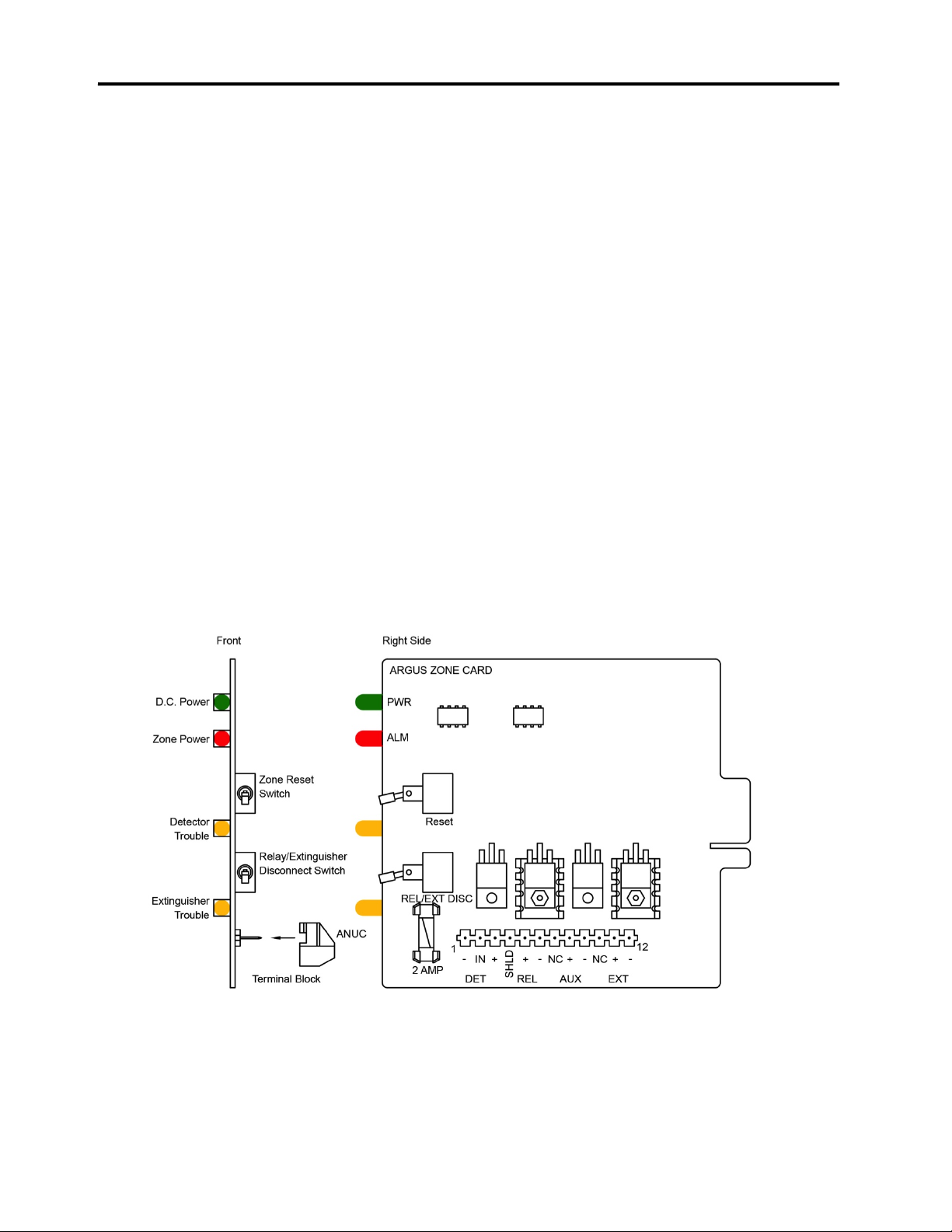

1.4 ZONE CARDS

Each set of detectors is wired to its own zone card located in the control panel. For

information on wiring zone cards, see section 2.4. This section includes a brief overview

of the LED indicators, switches, and fuses located on the card.

Indicators

•LED #1 – green Power Indicator (PWR): Indicates the presence of 24 volts DC

regulated voltage from the power supply regulator.

•LED #2 – red Alarm Indicator (ALM): Indicates an activation of the alarm circuitry

by the detector.

•LED #3 – amber Detector Trouble Indicator (DET): Indicates trouble in the external

circuits to and from the detector. It will illuminate when the reset switch is operated.

•LED #4 – amber Extinguisher Trouble Indicator (EXT): Indicates trouble in the

extinguisher firing circuit, such as extinguisher disconnect switch being in the open

position, a fuse is blown, open leads, etc.

Switches

•Reset Switch: a normally closed, momentary switch that controls 24 volts DC to the

detectors connected to the zone.

•When operated (moved to the “UP” position), it disconnects the 24 volts DC power

from the detectors, which automatically reset themselves. While operated the amber

indicator will flash and the trouble alert will beep.