Page 3, Rev. 7

23 Walpole Park South, Walpole, Massachusetts 02081, • Phone: 1-800-343-3381

www.sanborntechnologies.com • E-mail: info@sanborntechnologies.com

Normal Operating Procedures:

Before starting the unit check the free-oil level that has accumulated at the top of the

tank. It should be removed if the oil weir is not visible. To do this, open the oil

discharge valve, drain the oil into the oil tanks then close the oil discharge valve. The

height of the oil weir should be checked to ensure that coolant is not being discharged

with the oil. The discharge weir is set too low if coolant is being discharged into the oil

container. To raise or lower the oil weir use the tool provided and turn the weir

clockwise or counter-clockwise as indicated.

Check regularly to verify that the oil weir discharge pipe is not obstructed.

Start the pump and recheck the correct height of the suction pipe.

Maintenance Instructions:

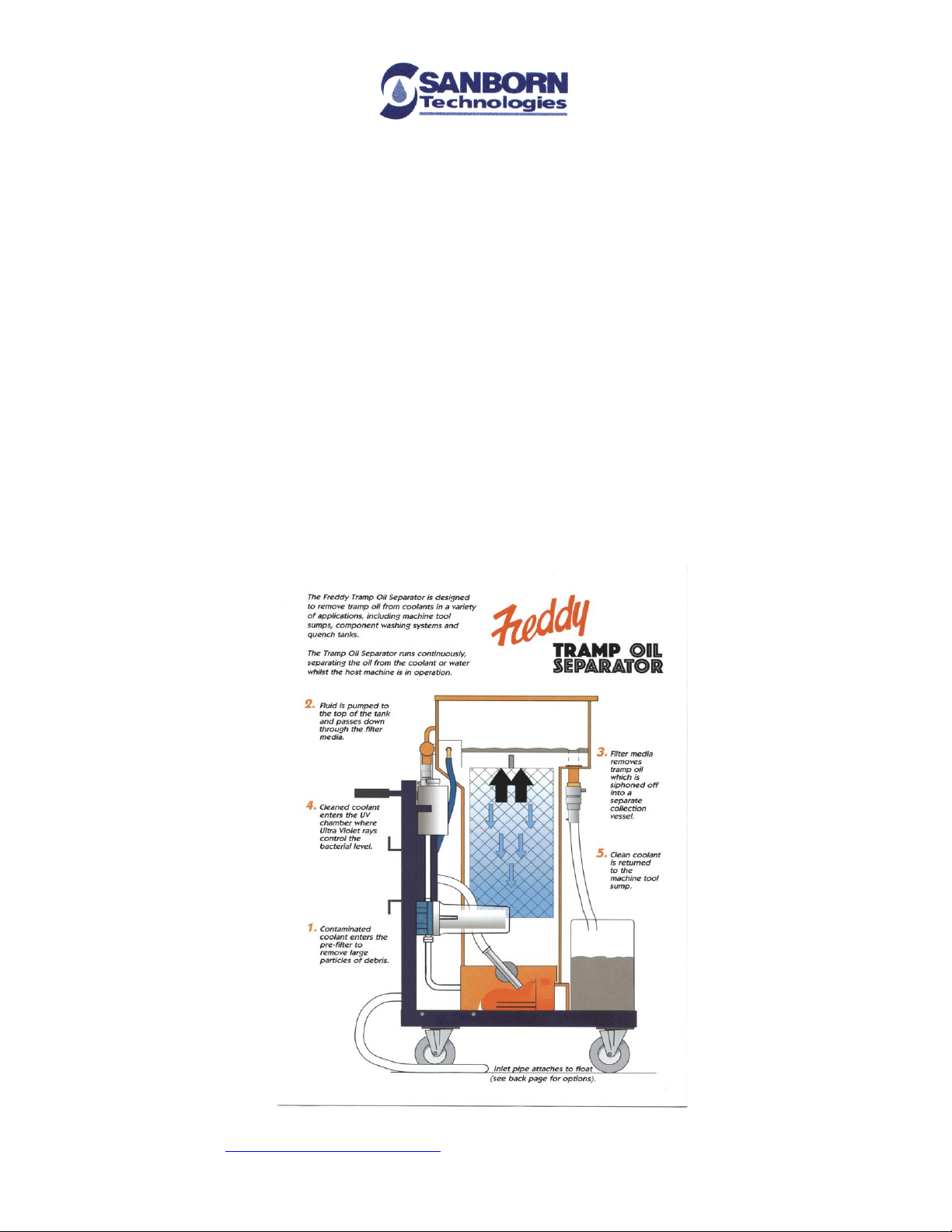

Since there are only a few moving parts in the Freddy TOS, maintenance consists of

cleaning or changing the prefilters cartridges as necessary, periodic flushing of the

sediment which may accumulate in the bottom of the unit, , and (rarely) cleaning the

filter media if it becomes clogged with sediment.

The filter media can be cleaned by removing the basket and using a hose or power washer

on the media. (See Precautions below)

Daily: Check all hoses for damage and verify connections are tight. Drain the oil from

the tank if necessary. Check the prefilters and change (or clean) as required. On air

operated models check the lubricating oil level and refill if required. Empty the oil

storage tank(s) as required.

Feed Rate:

If there is a reduction in the feed rate from the pump it could be due to one of the

following:

The prefilter is plugged. Replace or clean.

The suction pipe on the float is set too high. Adjust as necessary

The suction line is blocked or split. Replace as required.

The pump has worn and needs service

Precautions:

Always fill the Freddy TOS with clean fluid before processing at the machine tool sump.

This avoids depleting the fluid volume in the sump.

DURING NORMAL USE, IT SHOULD NOT BE NECESSARY TO DRAIN THE

TOS OR REMOVE THE BASKET OF MEDIA. If you want to drain the TOS or

remove the media, you must first remove the floating oil layer on the top of the unit.