i

Please Read Before Starting

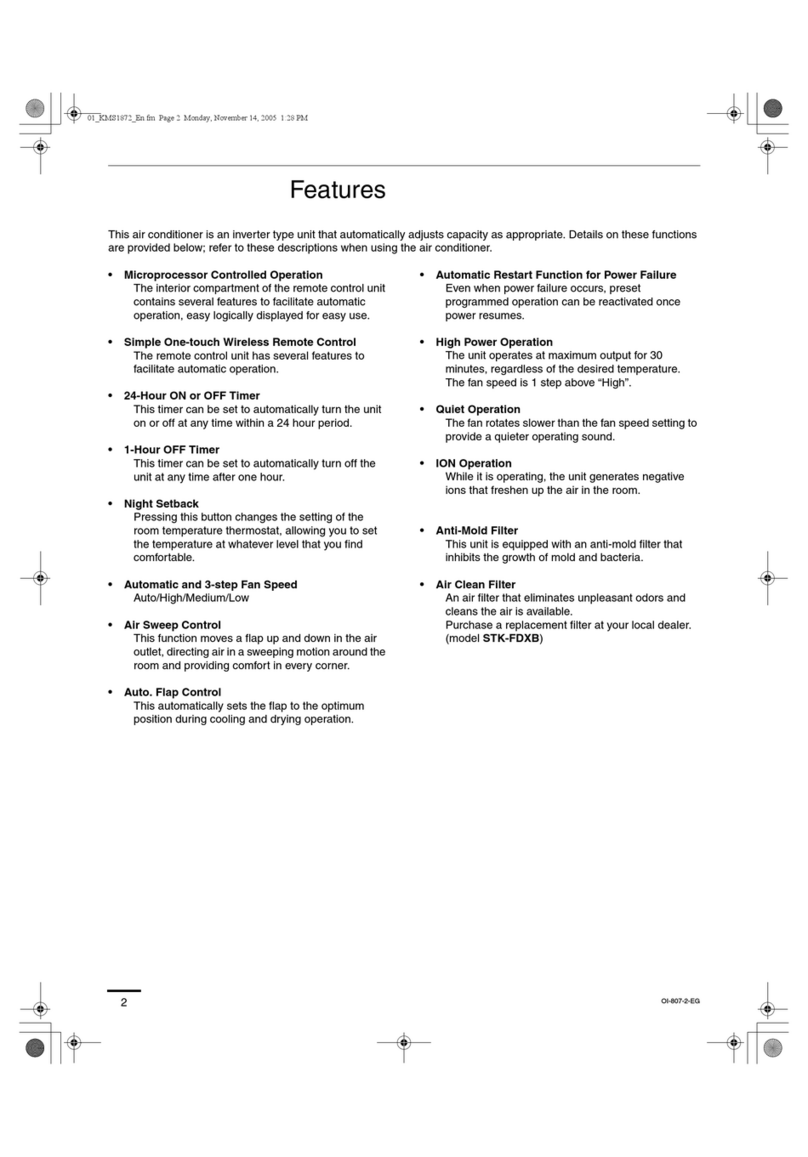

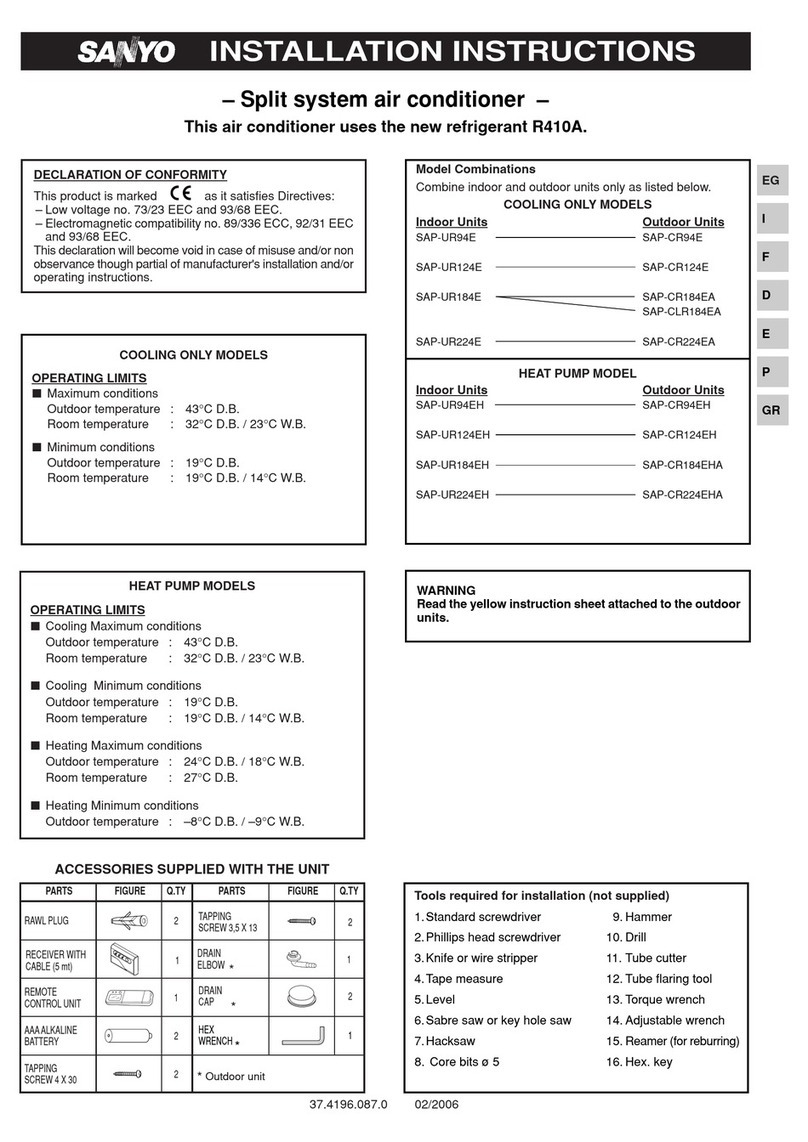

This air conditioning system meets strict safety and operat-

ing standards. As the installer or service person, it is an

important part of your job to install or service the system so

it operates safely and efficiently.

Carefully read this instruction booklet before beginning.

Follow each installation or repair step exactly as shown.

Observe all local, state, and national electrical codes.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

In Case of Improper Installation

When Wiring

ELECTRICAL SHOCK CAN CAUS

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

E

• Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this sys-

tem. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inad-

equate grounding can cause accidental injury or death.

•

When Installing…

…In a Room

Properly insulate any tubing run inside a room to preven

“sweating” that can cause dripping and water damage to

walls and floors.

t

…In Moist or Uneven Locations

…

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

•

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them, then

tighten the nut with a torque wrench for a leak-free con-

nection.

• Check carefully for leaks before starting the test run.

When Servicing

•

• Keep your fingers and clothing away from any moving

parts.

•

•

• Confirm after installation that no refrigerant gas is leak-

ing. If the gas comes in contact with a burning stove,

gas water heater, electric room heater or other heat

source, it can cause the generation of poisonous gas.

IMPORTANT!

For safe installation and trouble-free operation, you must:

Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or death.

WARNING

CAUTION

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including fail-

ure to follow the instructions in this document.

SPECIAL PRECAUTIONS

WARNING

Ground the unit following local electrical codes.

Connect all wiring tightly. Loose wiring may cause over-

heating at connection points and a possible fire hazard.

When Transporting

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting

to reduce strain on your back. Sharp edges or thin aluminum

fins on the air conditioner can cut your fingers.

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

When Connecting Refrigerant Tubing

Ventilate the room well, in the event that is refrigerant

gas leaks during the installation. Be careful not to allow

contact of the refrigerant gas with a flame as this will

cause the generation of poisonous gas.

Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical parts

and wiring.

Clean up the site after you finish, remembering to check

that no metal scraps or bits of wiring have been left

inside the unit being serviced.

CAUTION

Ventilate any enclosed areas when installing or testing

the refrigeration system. Escaped refrigerant gas, on

contact with fire or heat, can produce dangerously toxic

gas.

•

•

•

•

•

SM83018100.indbbSM83018100.indbb 2010/03/0119:23:252010/03/0119:23:25