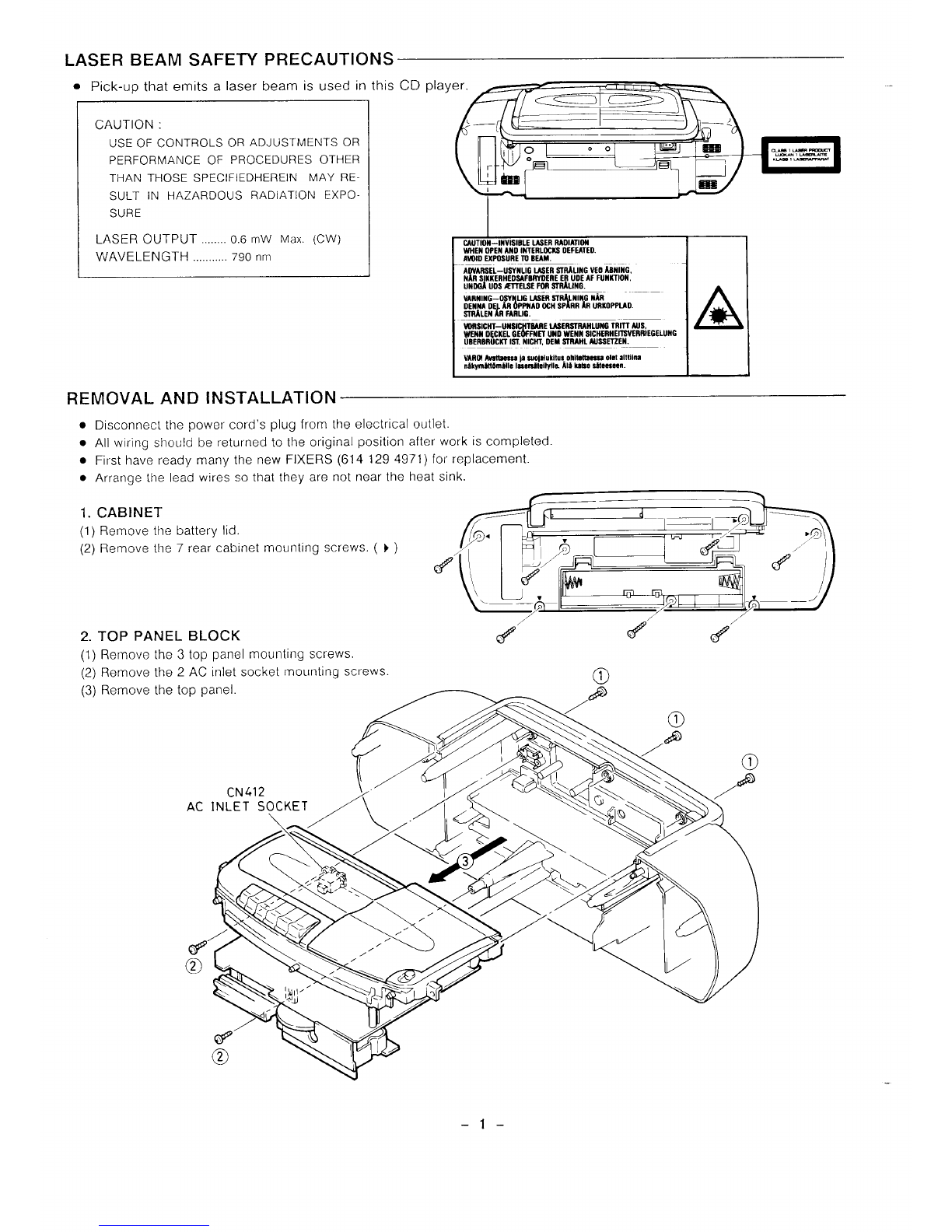

REPLACEMENT OF CD MECHANISM

.Note that the mechanism of the CD player is very delicate.

●It is very important that the spindle motor (which rotates the disc), and the sled motor (which cases the disc signals to be

tracked), as well as the gear and other components, operate smoothly, without eccelen{riclty.

●when handling the pickup, take care not to exert excessive force, and particular care should be taken not to touch the lens

or the drive circuit’s P. W. Board pattern.

1. Replacement of the spindle motor

.First, prepare the new turntable (C M3-2) and new special

washer (C M3-4) for replacement. CM3-2

The removed turntable will be deformed by the heat of the

soldering iron, and cannot be reused. CM3-1

.Prepare dial type calipers.

(l) The attached bonding material can be dissolved by using a

60 Wsoldering iron to heat the shaft at the under part of

the turntable (CM3-2) for about one minute.

(2) The turntable can then be removed from the shaft by very

carefully applying force upward at the center of the lower

surface of the turntable.

(3) Remove the two screws (CM3-3) and remove the spindle CM3-5

motor (CM3-5).

(4) Attach the special washer (CM3-4) to the spindle motor.

(5) Apply asmall amount of amixture of the “Three Bond

2001 and 2015F” bonding materials to the motor’s shaft.

(6) Initial the turntable as shown in the figure. Secure the turn-

table by pressing gently. Be sure to wipe away (by using a

price of cloth, or similar material) any bonding material

coming out of the hole.

Don’t attached bonding mater Ial

at the top of ;haft

IUT I

@

110

iol

\-

i1‘CM2

(SHAFT)

uu

Be sure to w!pe away

the bonding material.

\CH~CK PULLEY

mm

T)

2. Confirm of inclination for the turntable

(l) Connect the digital voltmeter as shown in the figure.

(2) Set the test disc (YEDS 18 =SONY or etc.), press the

PLAY button (Playback for the most inner music). F+ +

(3)At this time, record voltage value to indicate at the digital

voltmeter. 10 kohm

Unit Digital

(4) Access the most outer music, press the PLAY button 0.0033PF Voltmeter

(Playback for the most outer music). A

(5) Again at this time, record voltage value to indicate at the Vc

digital voltmeter. Low Pass Filter

(6) For reference at the recorded voltage of the most inner

music, Confirm at t300 rnV less than for recorded voltage

of the most outer music

-5-