SERVICE ADJUSTMENTS (Continued)

— 8 —

GRAYSCALE ADJUSTMENT

1. Set the picture controls to the Sports levels or Reset

(use MENU key and ▲or ▼ key or RESET key).

2. Turn off the receiver and disconnect the AC power cord

(120V AC line).

3. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

4. Select NO. 15 RB (Red Bias), NO. 16 GB (Green Bias),

and NO. 17 BB (Blue Bias) with ▲or ▼ key and set each

data to 0 with + or – key.

5. Select NO. 18 RD (Red Drive) and NO. 20 BD (Blue Drive)

with ▲or ▼key and set each data to 64 with + or – key.

6. Set NO. 19 GD (Green Drive Reduction) data to 8, NO. 53

SB (Sub Brightness) data to 32, NO. 54 SCO (Sub Color)

data to 7, NO. 55 STI (Sub Tint) to 20, and NO. 56 SSH

(Sub Sharpness) data to 12 with ▲or ▼, and + or – keys.

7. Turn Screen Control (T402) to minimum (fully counter-

clockwise).

8. Select the Service Menu NO. 73 (Bias Adjustments) with

▲or ▼key.

9. Advance Screen Control (T402) clockwise to obtain just

visible one color line. If line does not appear, place this

control to maximum (fully clockwise).

10. Raise each Bias Level with 3, 6, and 9 keys to obtain just

visible white line. (See Figure 5.)

11. Select the Service Menu NO. 72 DRV (Drive Adjustments)

with ▲or ▼key.

12. Adjust Red and Blue Drive Levels alternately with 1, 3,

7, or 9 key to produce normal black and white picture in

highlight areas. (See Figure 6.)

13. Check for proper grayscale at all brightness levels.

To turn off the Service Menu display, press the MENU key.

Note: If Grayscale Adjustment is made after picture tube

replacement, check Brightness Level Adjustment.

BRIGHTNESS LEVELADJUSTMENT

Note: Grayscale, RF AGC, Video Level, and High Voltage Check

must be adjusted before attempting Brightness Level

Adjustment.

1. Connect a color-bar generator to the antenna terminals.

2. Switch the generator to the crosshatch pattern.

3. Reset the picture controls to the Sports levels.

4. Connect voltmeter (high impedance) + lead to terminal

TP51 and – lead to terminal TP50 on main board. Set

voltmeter for 1.5V ~ 3V range.

5. Turn off the receiver and disconnect the AC power cord.

6. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

7. Select NO. 53 SB (Sub Brightness) with ▲or ▼key.

8. Adjust the data with + or – key for 680 mVDC.

9. Press the MENU key to turn off the Service Menu display.

10. Check brightness level on every active channel, readjust

(repeat steps 5 ~ 9), if necessary.

Note: Do not set to excessive brightness level, otherwise

the contrast level will be suppressed.

HIGHVOLTAGE HOLD-DOWNTEST

Every time the receiver is serviced, the HIGH VOLTAGE

HOLD-DOWN circuit must be tested for proper operation by

following these steps:

1. Connect receiver to 120V AC line. Tune receiver to active

channel. Reset the picture controls to the Sports levels.

2.Check that the voltage measured between TP7 and TE7

(ground side) is within 16.5 VDC to 21 VDC. If the voltage

is out of this range, the Hold-Down Circuit must be checked.

3. Connect a DC Voltage supply to TP7 and TE7 through a

100 ohm 1/4W resistor. Adjust the DC voltage to 23 VDC.

The receiver should shutdown, losing raster and sound.

Then the receiver should turn off automatically. This

reaction indicates that the Hold-Down circuit is function-

ing properly. If the receiver does not shutdown, a

malfunction is indicated and its cause must be found and

corrected.

4. To obtain picture again, remove the DC Supply and wait

a few minutes. Now turn on the receiver.

HIGHVOLTAGE CHECK

Note: +B (+130V) Voltage Check and Grayscale Adjustment

must be completed before attempting High Voltage

Check.

1. Connect high voltage voltmeter – lead to ground, and

connect + lead to anode of picture tube.

2. Tune receiver to an active channel and confirm TV is

operating properly.

3. Eliminate the beam current by adjusting the contrast and

brightness controls to minimum.

4. Confirm high voltage is within 28.6 KV and 33.5 KV. If

reading is not within range, check horizontal circuit.

No high-voltage adjustment is provided on this chassis.

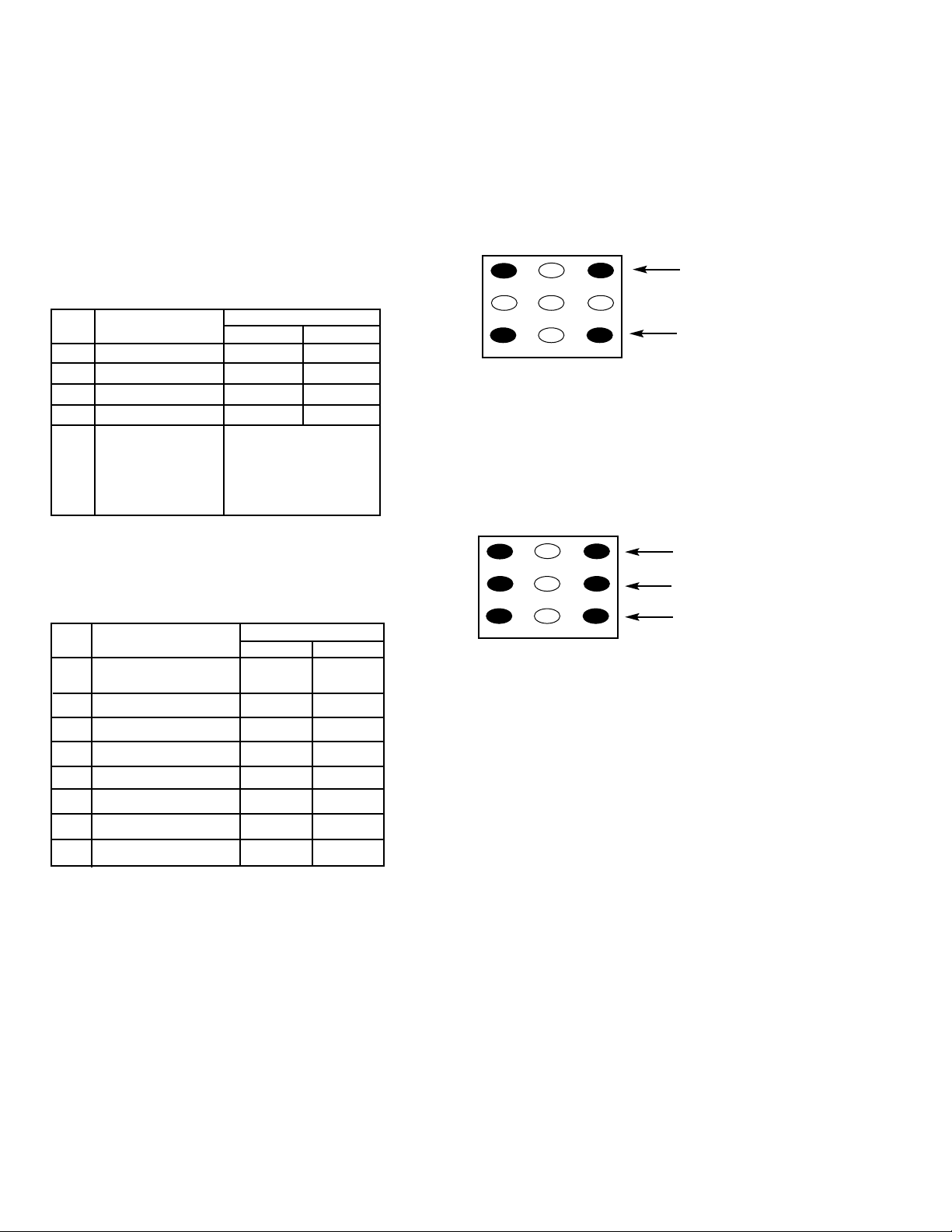

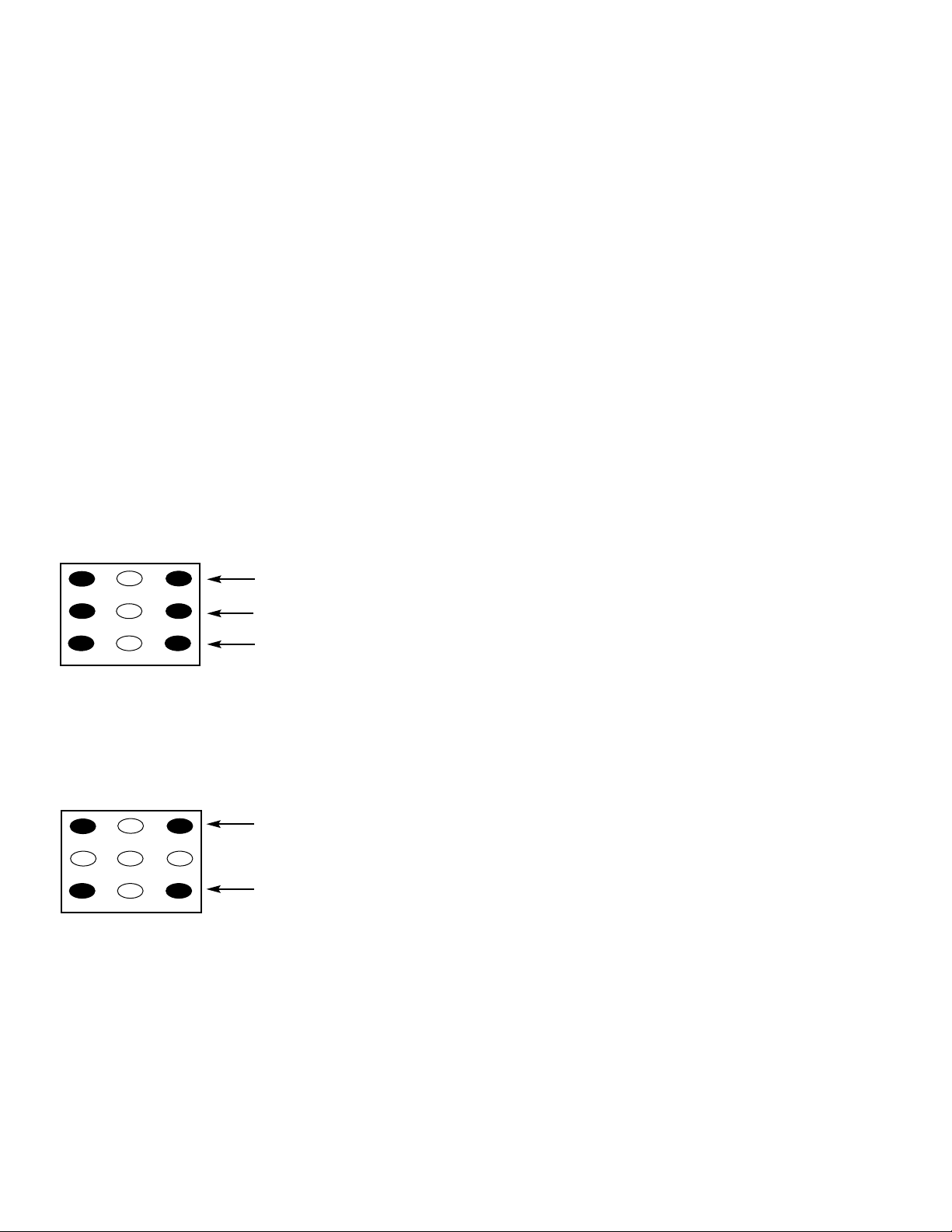

123

456

7 98

RB(–) RB(+)

BB(–) BB(+)

(N/A)

GB(–) (N/A) GB(+)

(N/A)

FOR RED BIAS ADJUSTMENT

FOR BLUE BIAS ADJUSTMENT

FOR GREEN BIAS ADJUSTMENT

Figure 5. Remote Control Number keys’ functions in

Service Menu NO. 73

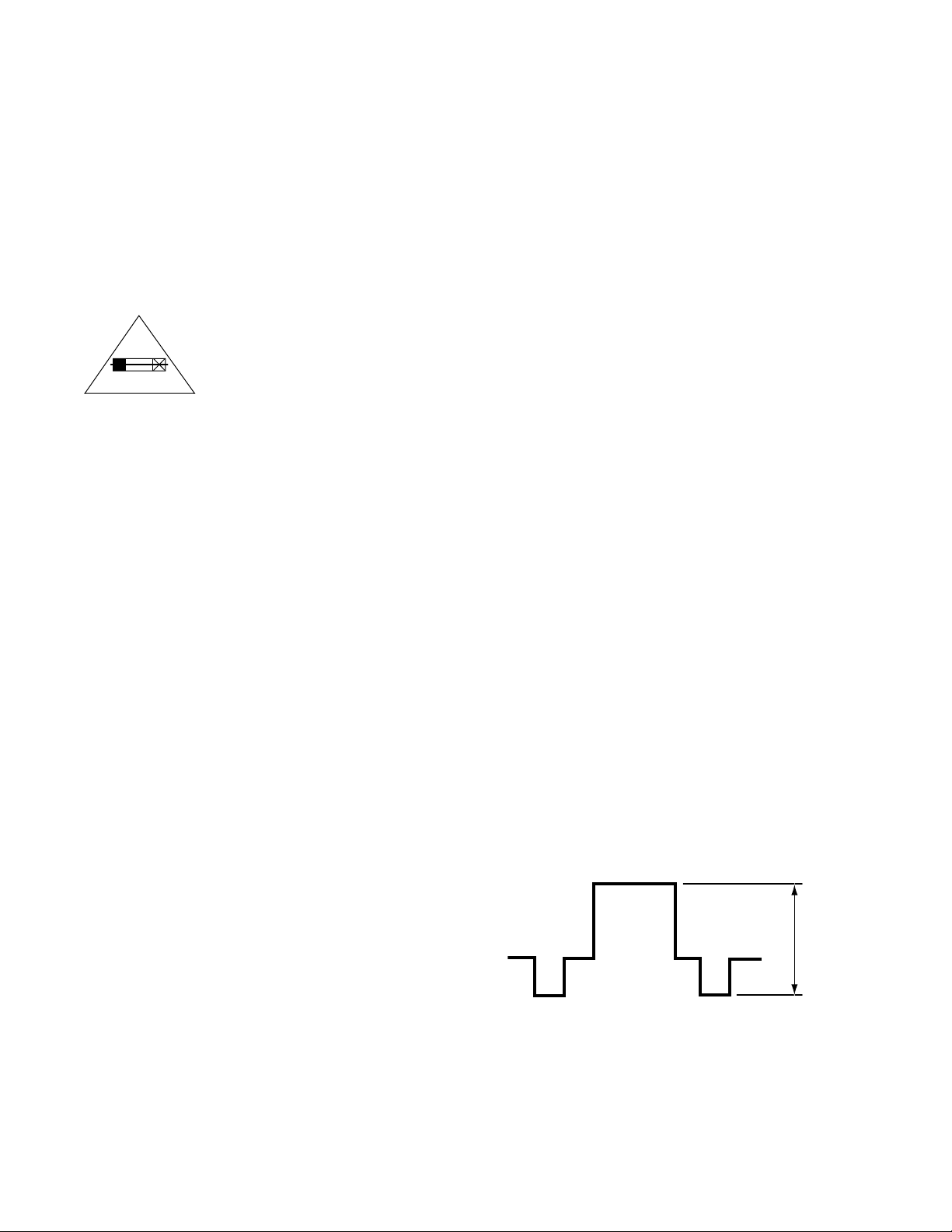

123

4 5 6

7 98

RD(–) RD(+)

BD(–) BD(+)

(N/A)

(N/A) (N/A) (N/A)

(N/A)

Figure 6. Remote Control Number keys’ functions in

Service Menu NO. 72 DRV

FOR RED DRIVE ADJUSTMENT

FOR BLUE DRIVE ADJUSTMENT