7

Commisioning

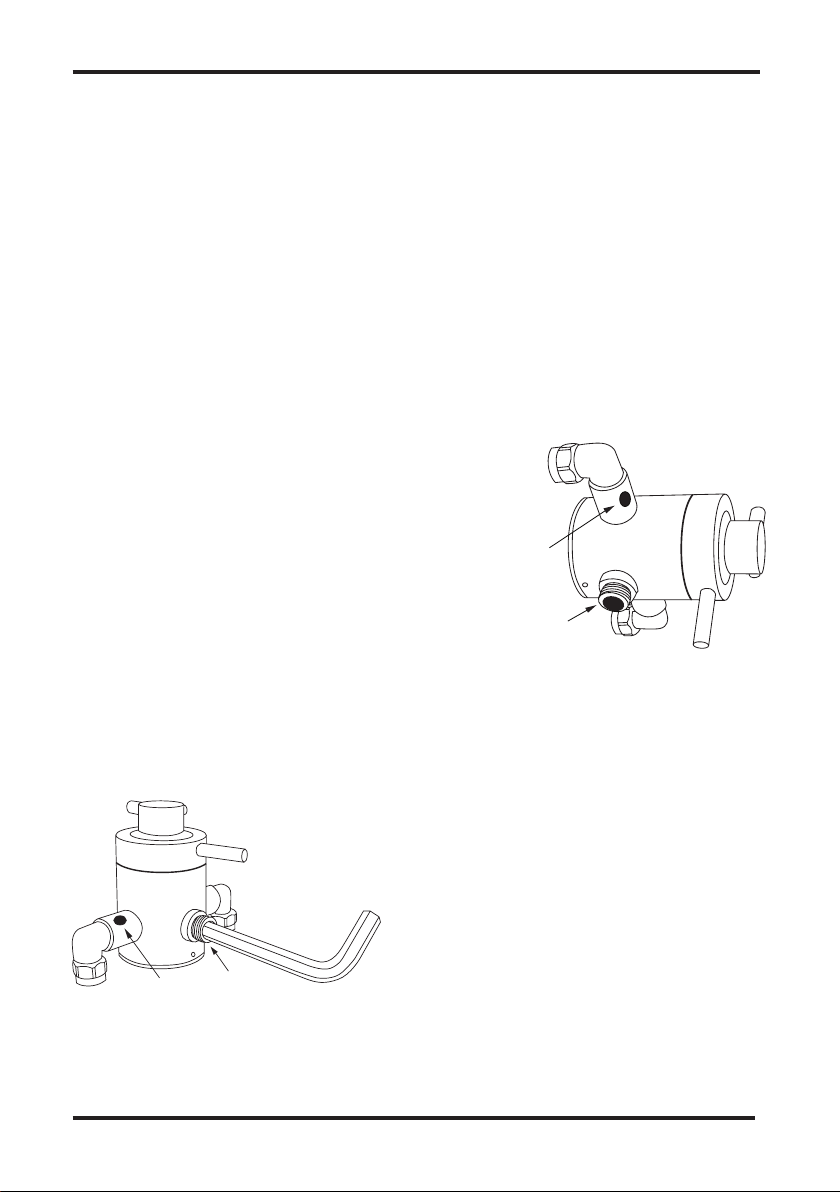

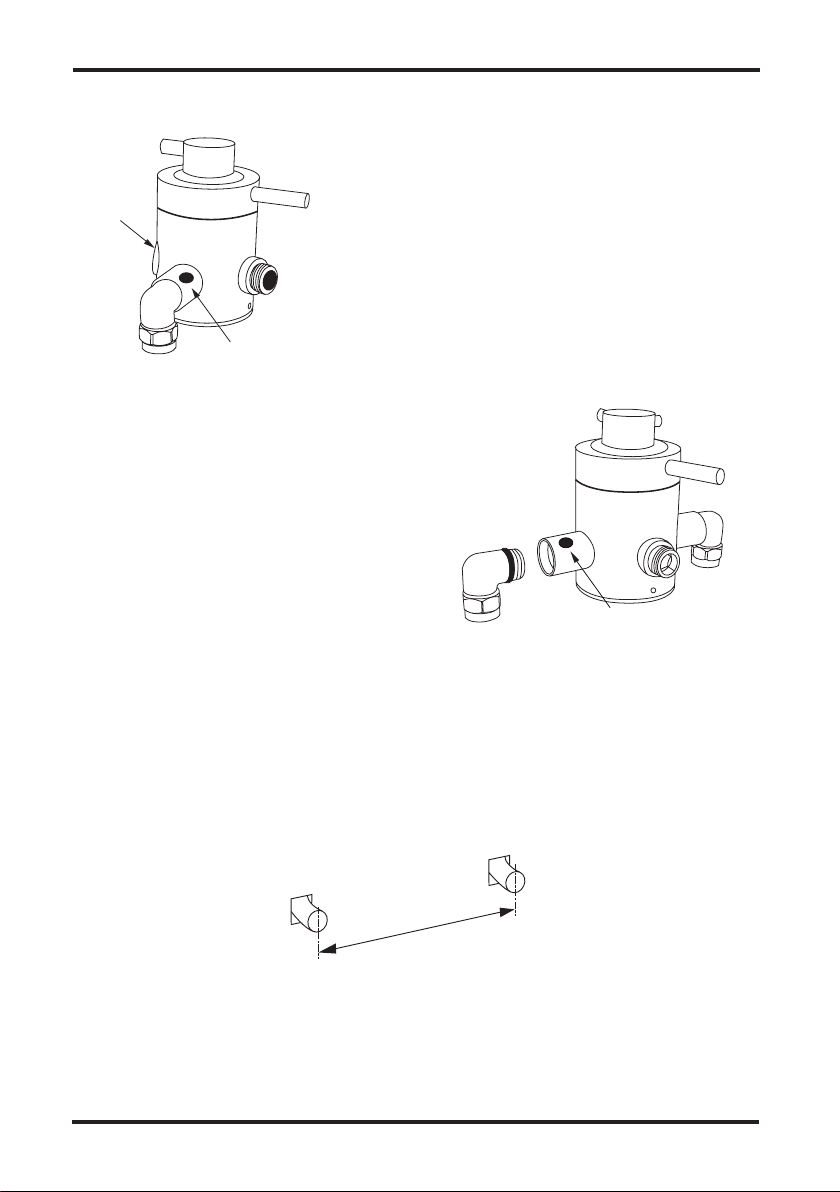

Ensure both isolation valves are fully open on the hot and cold water supplies.

With the temperature control handle in the pre-set ‘stop’ position, turn on the shower

and let it flow until the hot water temperature has stabilised. Check the temperature

is 38˚C +/-2˚C.

If your temperature is not 38˚C the following operation should only be carried out by

a competent person:

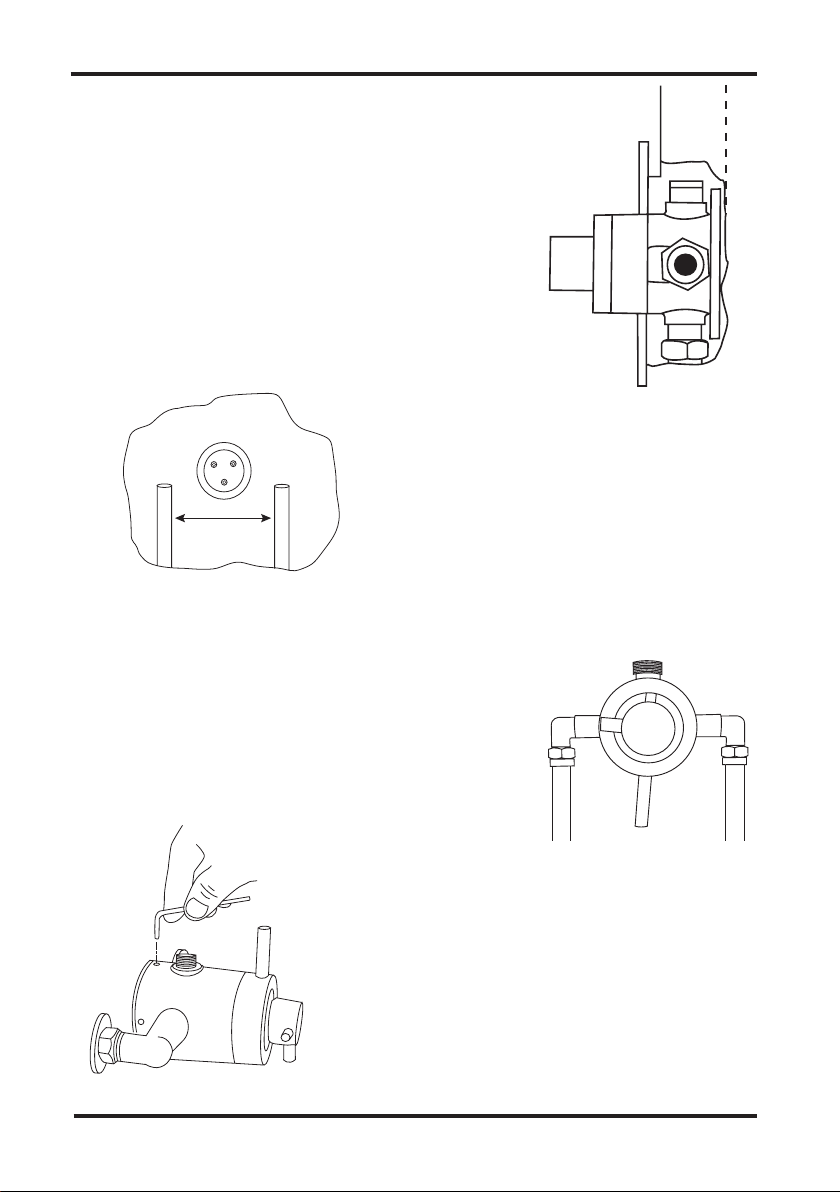

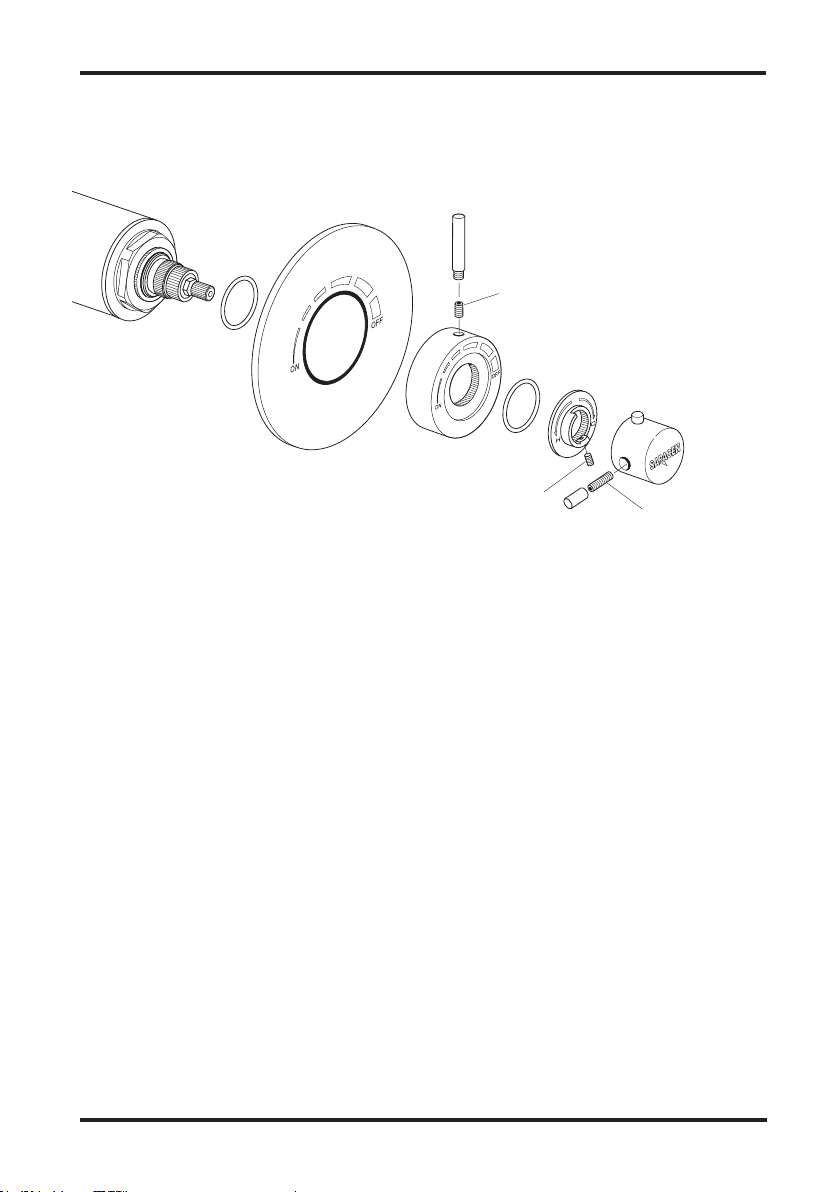

Position the temperature control knob at the stop. Unscrew the temperature lever to

expose the grub screw, use a 4mm allen key to remove the screw which allows the

temperature control handle to be removed.

Turn the spindle by hand (using grips may damage the slines on the control

and prevent the handle from gripping upon re-aeseembly) to adjust the pre-set

temperature to the required setting of 38°C, turning clockwise will decrease and

turning anti-clockwise will increase the termperature, test the water outlet using a

calibrated temperature probe, once set re-assemble the control handle.

Recommended Outlet Temperature & Performance Checks

Application Recommended Temperature

Shower 41°C

Please note:

• The mixed water temperature can be 2°C above the recommended maximum set

outlet temperatures.

• The mixed water temperature at the terminal fitting should never exceed 46°C. It

is not a safe bathing temperature for adults or children.

• The British Burns Association recommends 37 to 37.5°C as a comfortable bathing

temperature for children. In premises covered by the Care Standards Act 2000,

the maximum mixed water outlet temperature is 43°C.

Performance Checks

The performance of the Saracen Thermostatic Shower Control should be checked

on an annual basis and verified against the original installation performance. The

following check should be carried out:

• Check the mixed water temperature at the outlet using a callibrated temperature

probe

• Carry out the cold water supply isolation test by isolating the cold water supply to

the bar shower, wait for five seconds if water is still flowing check the temperature

is below 48°C

If there is residual flow, then this is acceptable providing the temperature of the

seeping water is no more than 2°C above the designated maximum water outlet

temperature setting of the valve.