SAS/op/proc/forks/operator man/Quick Coupler /SAS Quick Coupler Manual v3.pub 9:52 AM 3/30/2021 © 2021 S.A.S. of Luxemburg, LLC PAGE 7

INSTALLATION (PAGE 7)

SAS™ QUICK COUPLER

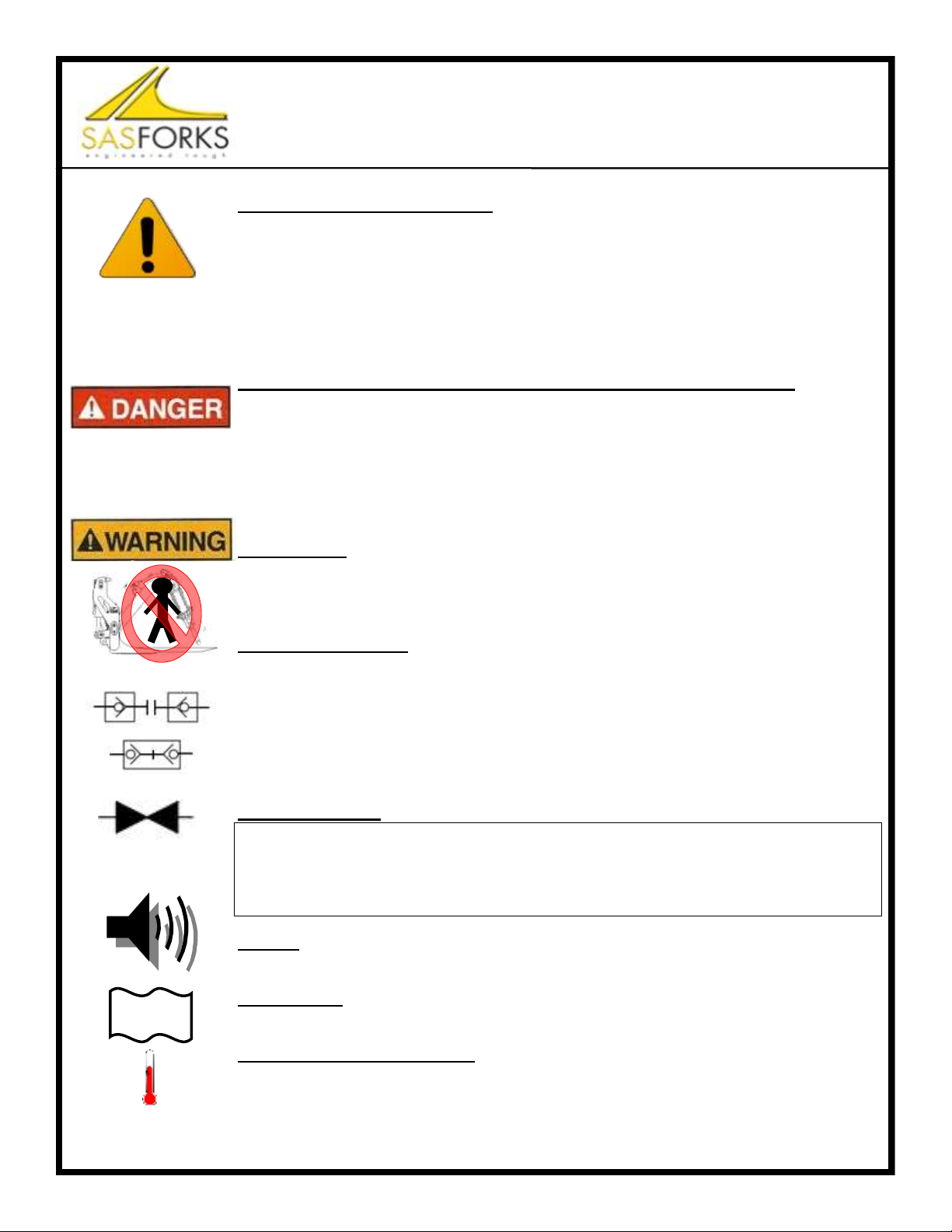

STEP 1 - PREPARATION:

• Establish a safe work area. A flat surface clean work area without trip hazards.

• Park wheel loader on firm level ground.

Lower exiting attachment (ie: bucket) to rest on ground.

Set parking brake and turn engine off.

• Follow wheel loader manufacturer’s instructions to depressurize hydraulic system.

• Do not work under a lifted object, loader arms or Quick Coupler. Avoid pinch & crush hazards.

• Remove existing pinned on attachment.

• Inspect pins & bushings in machine arms, replace as necessary.

STEP 2 - INSTALLATION:

• Apply grease to pins, bushings and pin holes on Quick Coupler.

• Align pin holes, insert pins and secure pins properly.

• Grease all pin zerk points.

STEP 3 - HYDRAULIC CONNECTION:

• Option #1: Electric pump kit from SAS Forks (diagram on next page)

• Option #2: Bucket roll back hydraulics with solenoid valve/switch.

• Option #3: Use 3rd spool auxiliary hydraulics on loader.

• Reference matching parts page within this manual to determine

maximum psi. (either 3,500; 5,000; 6,000). Have hydraulic pressure set below maximum.

• Determine hose length to avoid creating tension in all positions.

• Avoid excessive length that hoses would hang down to ground.

• Install high pressure hydraulic hoses. Recommend hose psi. to exceed cylinder requirements.

STEP 4 - TEST ROLL FORWARD AND ROLL BACK:

• During this test of motion, ensure smooth lifting & tilting of Quick Coupler. Watch for undesirable

contact between wheel loader lift arms and Quick Coupler. Also watch for hose pinch points.

• Begin testing by moving control levers slowly:

A. With Quick Coupler near ground level, fully roll back.

B. With Quick Coupler lifted high, fully rotate to dump position.

• Contact SAS FORKS™ if you experience interference issues to discuss stop options.

STEP 5 - TEST CYLINDER AND LOCKING PIN ENGAGEMENT:

• Engage hydraulics to actuate cylinder within Quick Coupler to extend Locking Pins.

• Visually verify Locking Pins are extended fulling into the exterior pin holes on the Quick Coupler.

• A few cycles of extend and retract maybe required to remove air from lines.

STEP 6 - CHECK & FILL HYDRAULIC FLUID:

• After installation test, check wheel loader hydraulic fluid level and fill as needed.

S.A.S. of Luxemburg, LLC, 133 Center Drive Hwy 54, PO Box 260, Luxemburg, WI 54217 USA

Phone: 920-845-2198 • 1-877-SAS-FORK • Fax: 920-845-2309 • Web: www.sasforks.com

Installation of purchased attachment may void machine manufacturer warranty, if any.

►Installation of QUICK COUPLER on wheel loader requires interfacing with high

pressure hydraulic system. Installation should only be performed by qualified indi-

viduals, such as an experienced Heavy Equipment Service Technician. Failure to

follow these instructions and precautions in wheel loader manufacturer’s service

manual can result in serious damage to equipment and/or result in injury or death.

►Failure of hydraulic system or high pressure fluid leaks can result in serious injury

►Use caution while installing, testing & operating this unit. Be aware of and avoid:

-Pinch Points, -High Pressure hydraulic fluids or stored energy, -People in the area.