** EUROPE ONLY

10/2019 PN 10900 /REVR 4

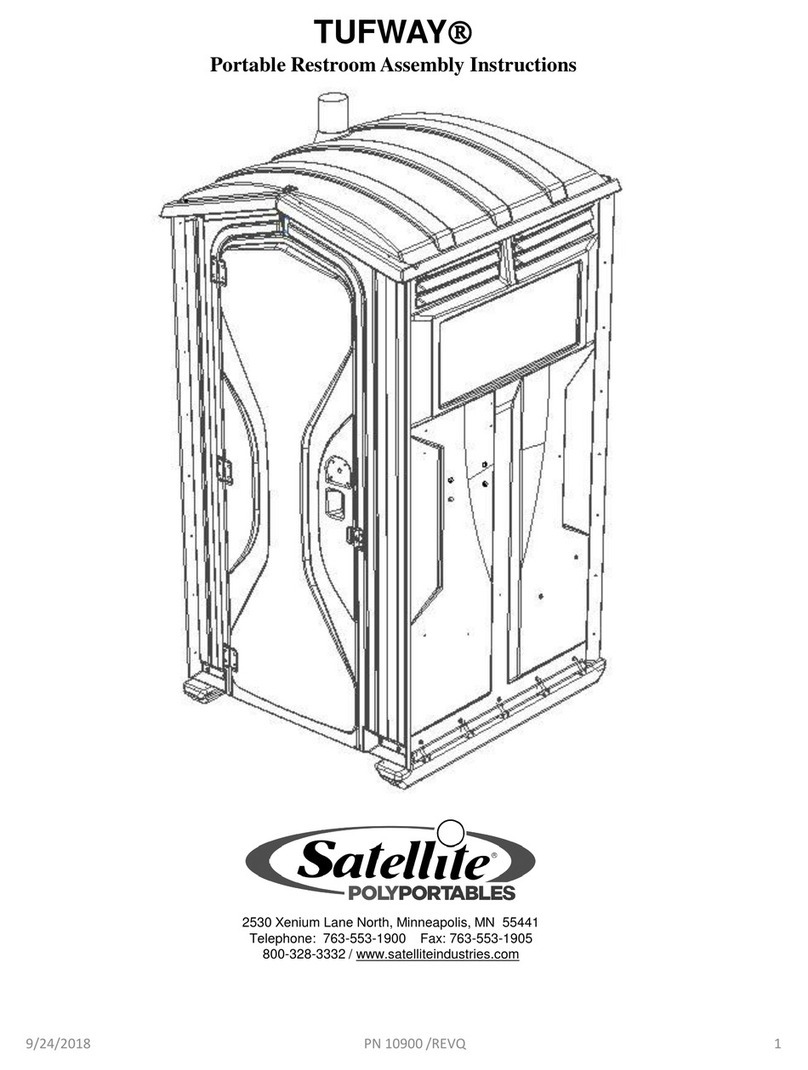

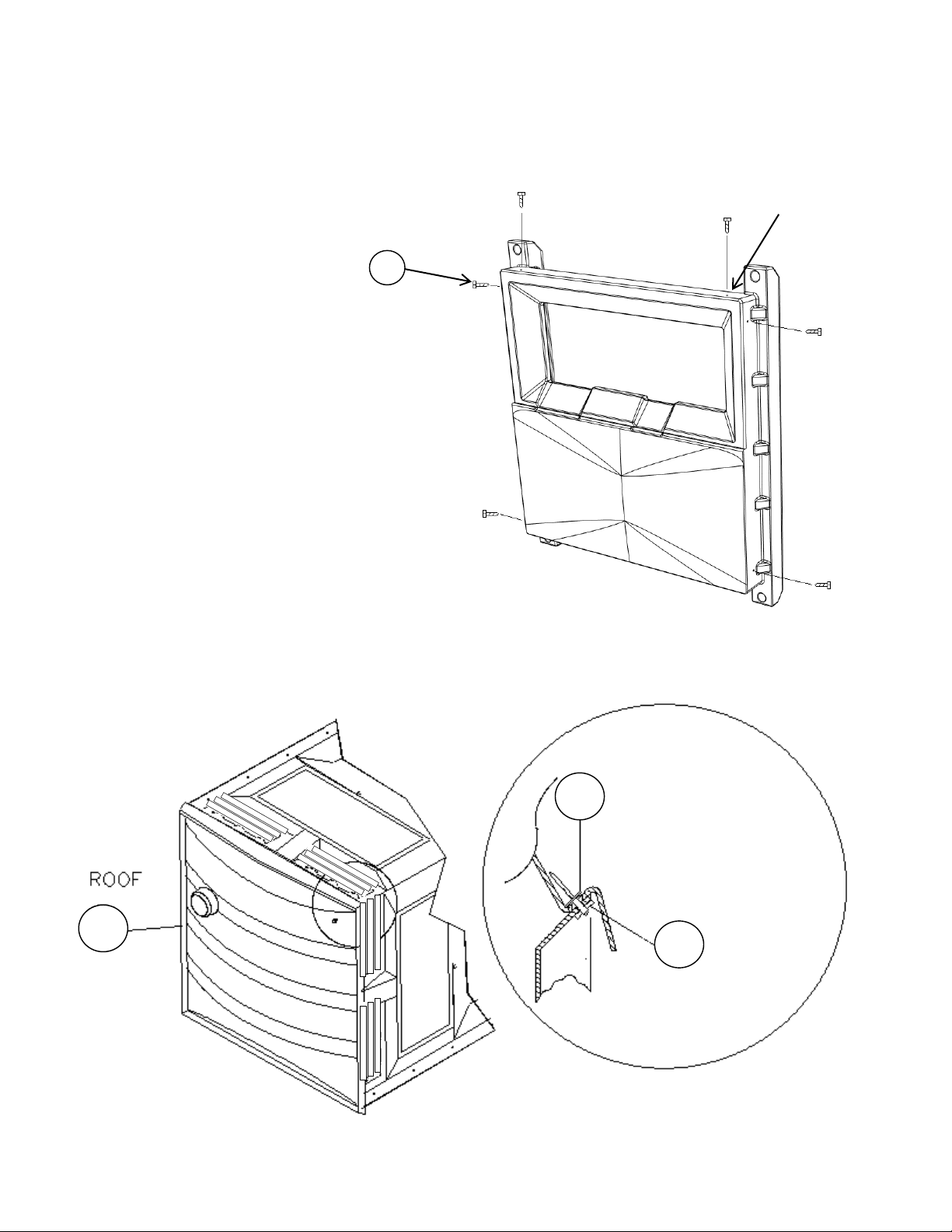

STANDARD TUFWAY

10 14133 1 VENT PIPE. 4 X 62-1/2 GREY

914119 1 URINAL, STAND OVER DGRY

810553 1 TANK, TUFWAY DGRY

710570 1 SEAT, TOILET

616045 1 ROOF, TUFWAY DOME

522209 1 HOOD- PAPERGRD 3 ROLL DGRY

22748 1 HDWE, TUFWAY 3 ROLL POP RIVET

415450 3 DESIGN, TUFWAY PANEL

315562 1 DESIGN, TUFWAY FRONT ASSY (STD)

216050 2 CORNER MOLDING II BLACK PUNCH

1 E

1 D

1 C

1 B

1 A

19014 1 BASE, TUFWAY ROTO MOLD DGRY

10033 1 BASE ASSY- IMPACT GRID FLOOR

10034 1 BASE ASSY- IMPACT SOLID FLOOR

40014 1 BASE, GB DIRT BUSTER

22234 1 BASE- BLOWMOLDED

ITEM PART# QTY DESCRIPTION

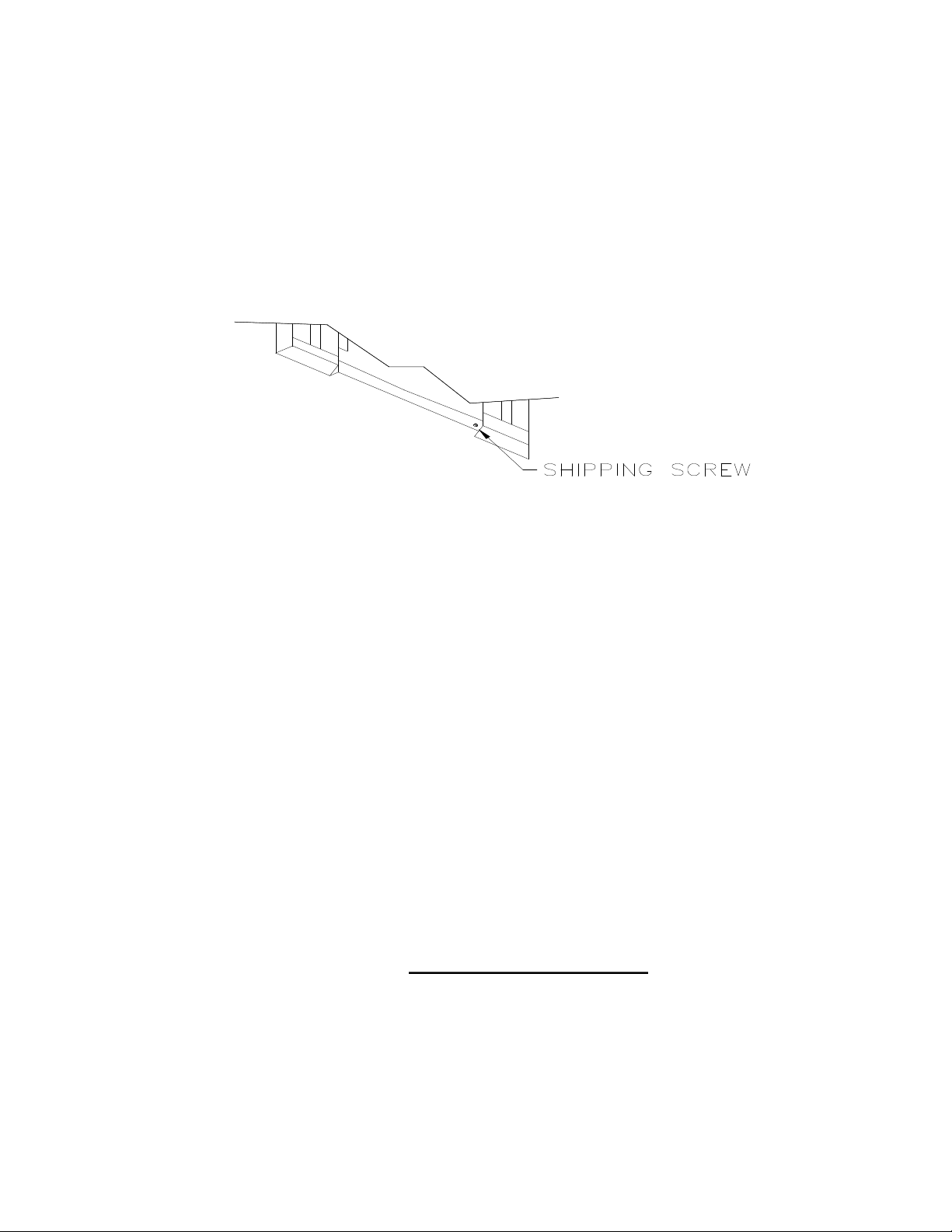

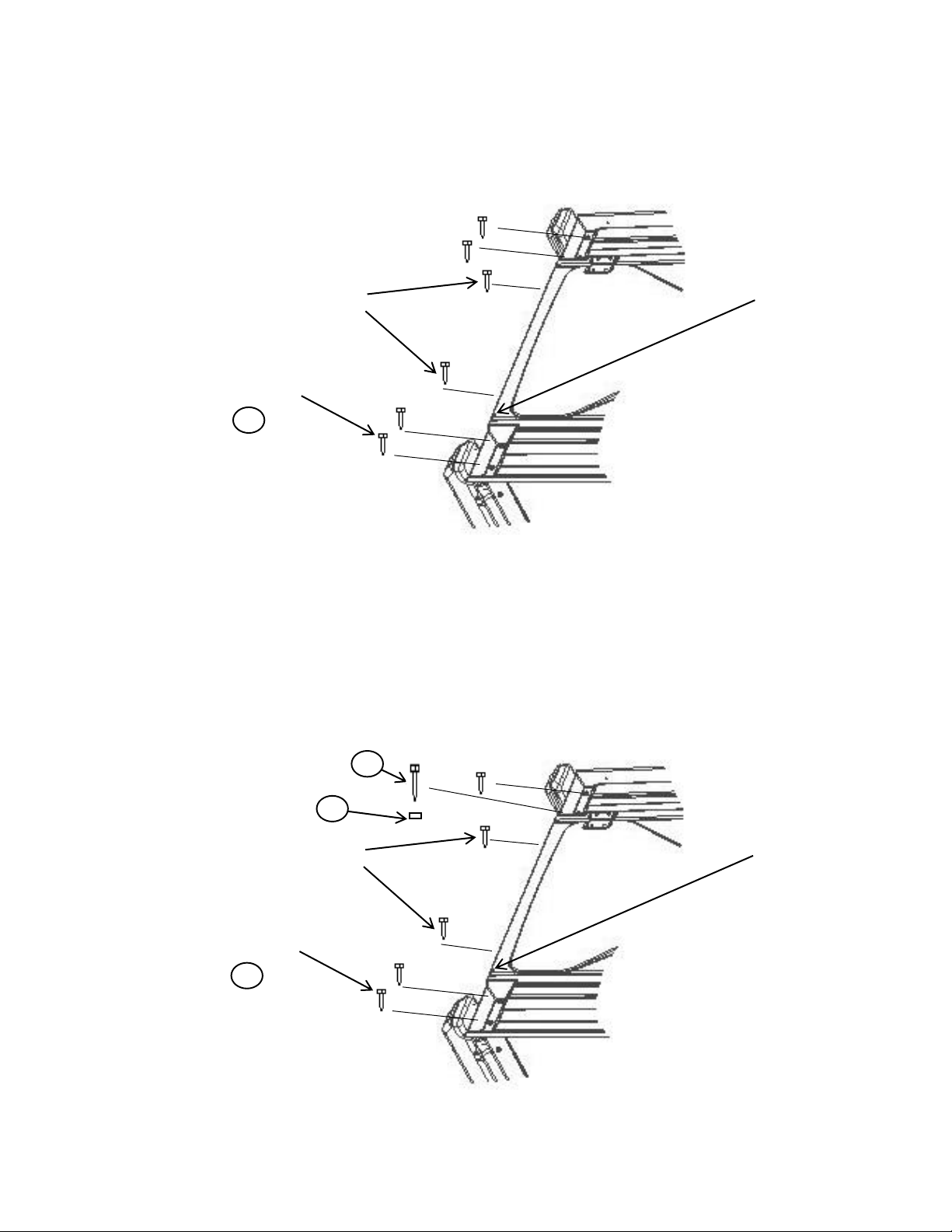

HDWE, TUFWAY 3 ROLL POP RIVET 22748

19 11315 56 WASHER- 3/16” RIVET STNLS

18 22310 1 SPINDLE- PRGRD II 3 ROLL METAL

17 13860 30 SCREW, #14 X 1-1/2 W/WSH GOLD

16 10122 4 SCREW, #10 X 3/4 PN PH TAP

15 22738 6 RIVET, #68 POP W/RUBBER WASHER

14 11054 22 RIVET, #68 AAL POP

13 22737 12 RIVET, #66 POP W/RUBBER WASHER

12 11030 16 RIVET, #66 AAL POP

11 14767 1 LATCH, RESTROOM PLASTIC

EUROPE ONLY HARDWARE

22 18191 1NUT, 5/16” SERRATED FLANGE

21 13173 1BOLT’ 5/16 X 3-1/2 HWHD

20 22384 6 BOLT- ¼-20 X 1-1/4 DOG PNT WSH

**

Use with Roto Base only

11

12

13

14

15

16

17

18

20

21

22

19

PN 13173

PN 18191

* Used With Blow Molded Base Only

*