www.saundersI-VUE.com

www.cranechempharma.com

Quick Start Guide Table of Contents

Basic Safety Instructions 2

Scope of Supply 3

Overview 4

Basic Installation Guide & Hazardous Area Installation 5

(Automatic) Self-Calibration (Integral Solenoid) 9

Hand-Calibration (Remote Solenoid) 10

Switching Outputs Options 13

Forcing the Integral Solenoid 14

Troubleshooting 15

Rev 1.00

Quick Start Guide Basic Safety Instructions

These instructions do not make allowance for:

Contingencies and events which may arise during the installation, operation, and maintenance of the sensor.

Local safety regulations; the operator is responsible for observing these regulations, also with reference to the

installation personnel.

High Pressure

Before dismounting pneumatic lines and valves, turn off the pressure and vent the lines.

To prevent damage, make sure that all the pneumatics connections are made correctly.

Electrical Risks

Before working on the sensor, switch off the power supply and prevent reactivation.

Observe applicable accident prevention and safety regulations for electrical equipment.

Hazardous Situation

To avoid injury, ensure:

That the system cannot be activated unintentionally.

Installation and maintenance may be carried out by authorized technicians only.

After an interruption in the power or pneumatic supply, ensure that the process will be restarted in a defined

and controlled manner.

The sensor must be operated according to the operating instructions

Warning:

Do not connect or disconnect while circuit is live unless location is know to be non-hazardous.

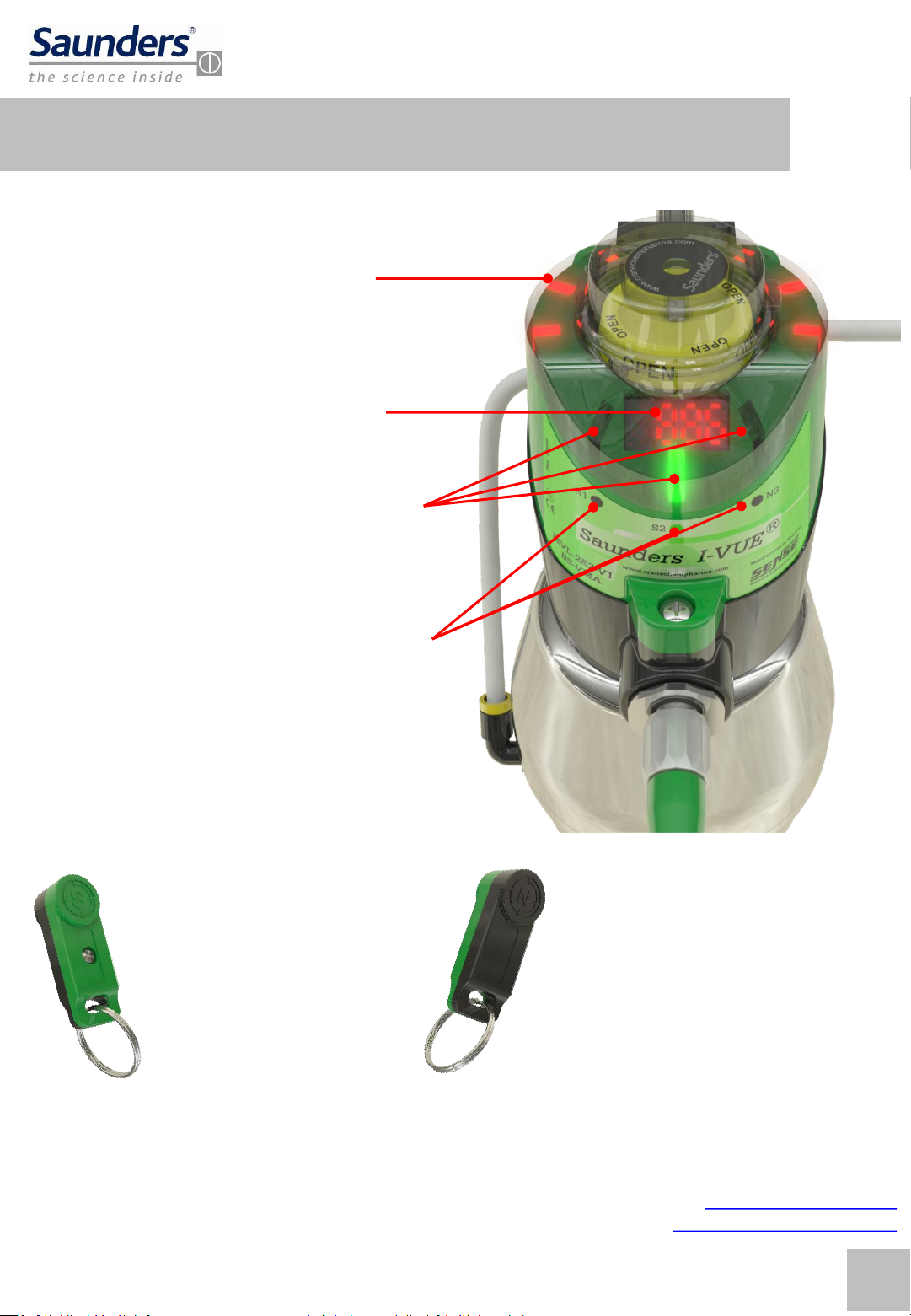

The Safety Lock device must be used with M12 and 7/8" electrical connections for use in Hazardous Area Class

1, Division 2. Substitution of components may impair suitability for class I, division 2.

2