Table of Contents

Table of Contents......................................................................................................................................... 1

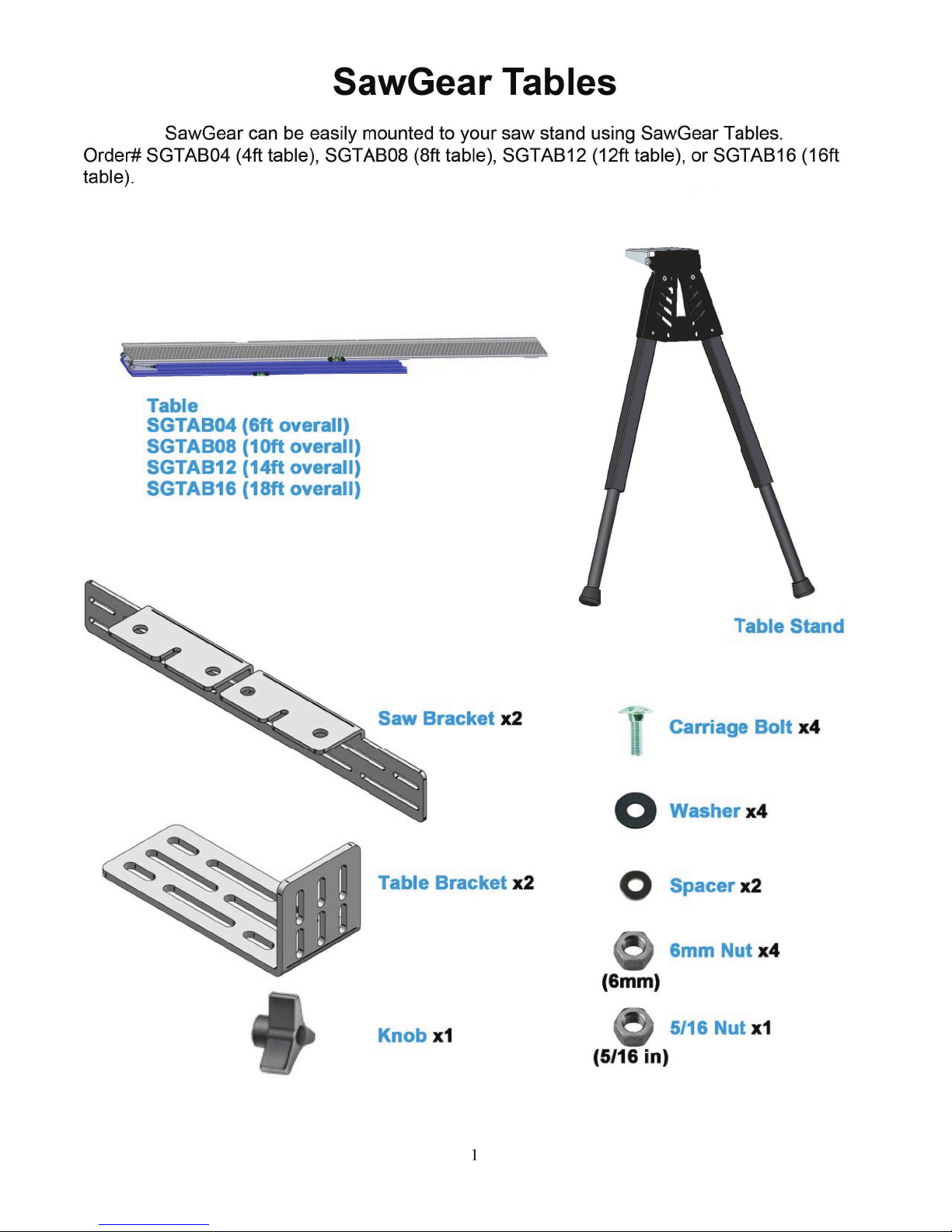

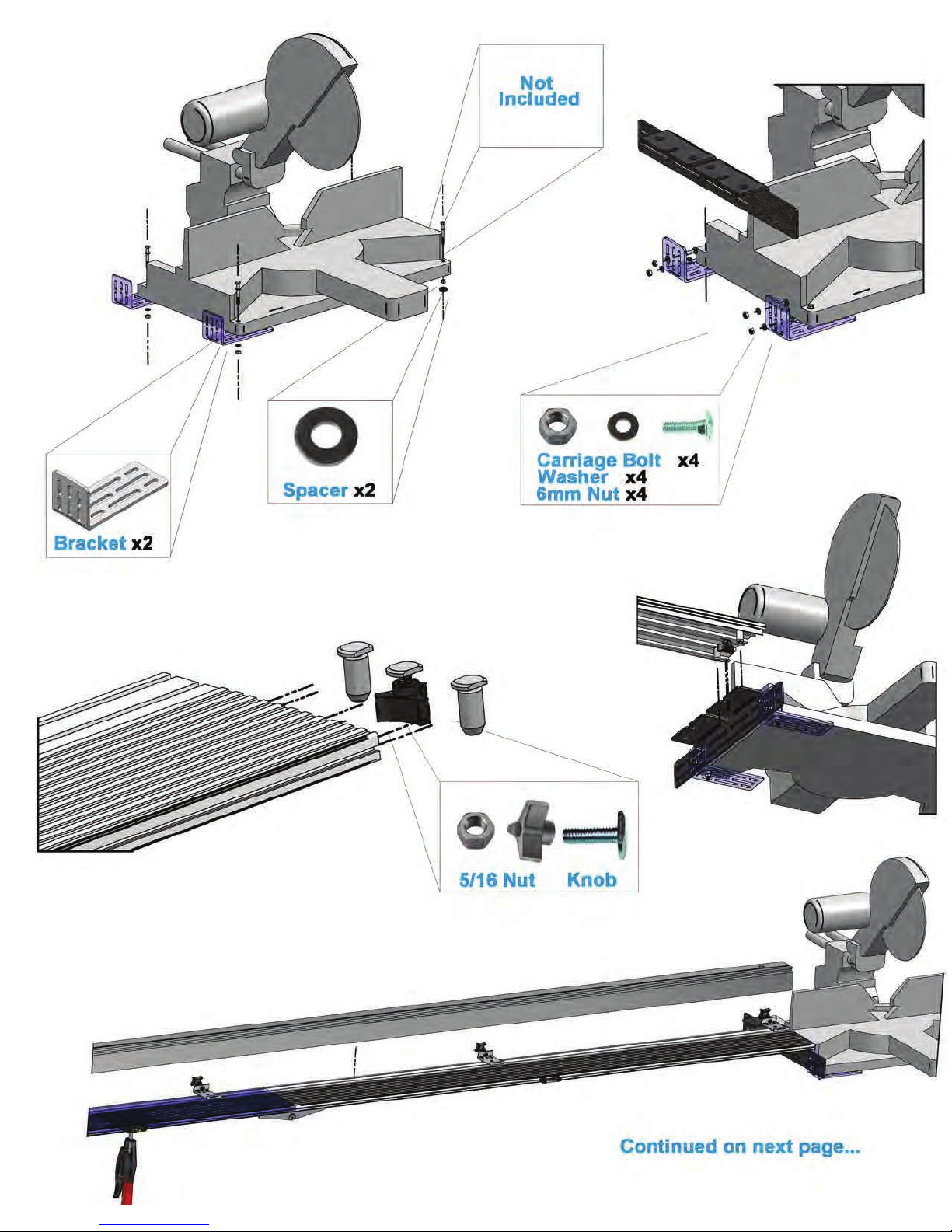

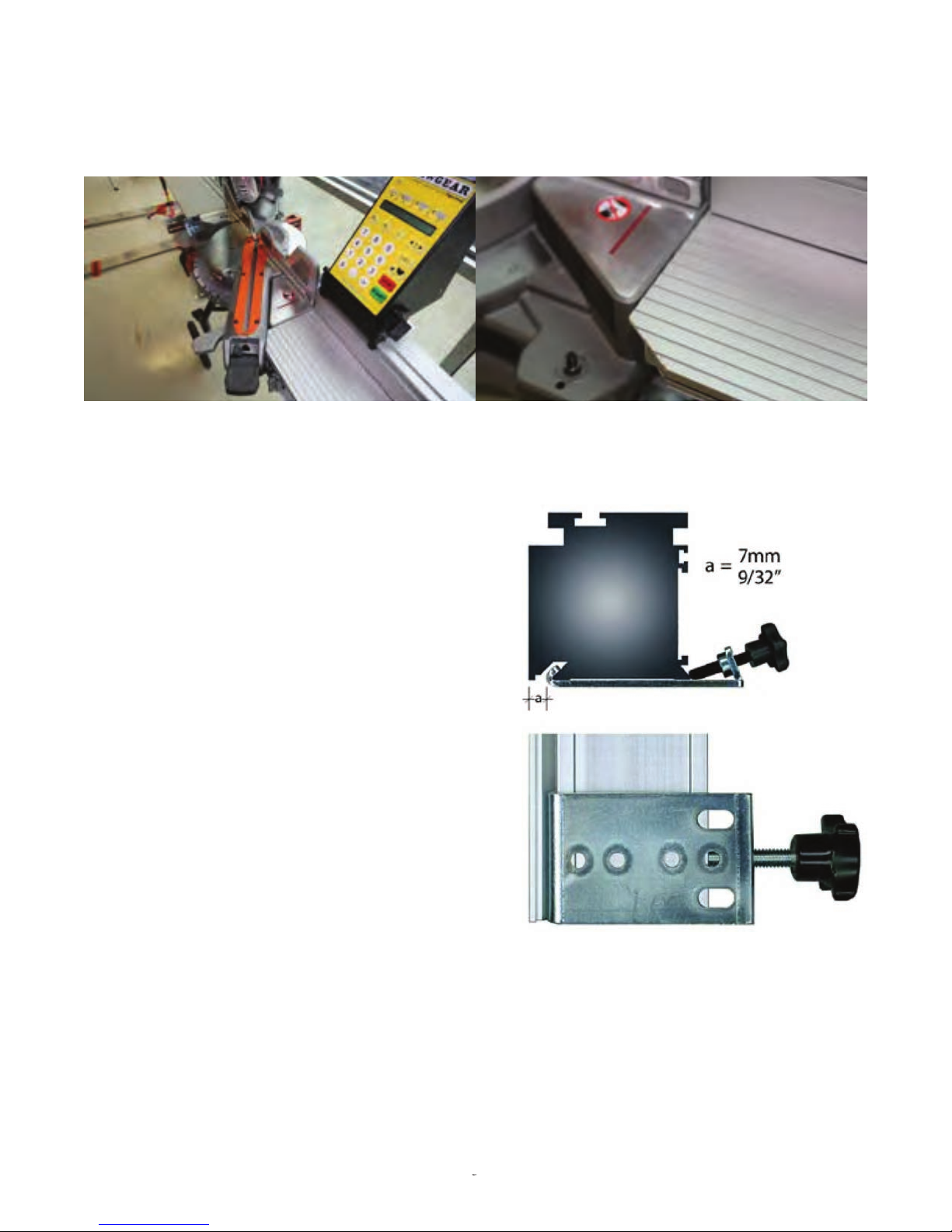

SawGear Tables............................................................................................................................................1

Trimming SawGear Tables.....................................................................................................................3

SawGear Bench Mount Brackets..................................................................................................................3

Secure SawGear in the brackets..............................................................................................................3

Dismounting SawGear from the saw stand............................................................................................ 3

Register Your Warranty............................................................................................................................... 4

Enable Your SawGear............................................................................................................................4

Miter Saw Accuracy.....................................................................................................................................5

Check Your Pivot Point..........................................................................................................................5

Adjusting the Miter Saw Pivot Point......................................................................................................6

Using SawGear to Adjust Pivot Point....................................................................................................6

SawGear Control......................................................................................................................................... 8

SawGear LCD Display.................................................................................................................................9

1st Power Up................................................................................................................................................ 9

Repeat a 1st Power Up................................................................................................................................10

Normal Power Up.......................................................................................................................................10

Start SawGear.............................................................................................................................................11

Set Sleep Mode...........................................................................................................................................11

Set Contrast............................................................................................................................................... 11

Password Protection.................................................................................................................................. 12

Change the Password..................................................................................................................................12

Deactivate the Password.............................................................................................................................13

Setting the Distance Between the Stop and the Blade................................................................................14

Calibrate Straight Cut Distance............................................................................................................14

Calibrate Miter Cut X Distance ...........................................................................................................14

Calibrate Miter Cut Y Distance ...........................................................................................................15

Calibrate Miter Cut Z Distance ............................................................................................................15

Calibrate Increment Distance.............................................................................................................. 15

Straight Cutting......................................................................................................................................... 15

Basic Operation................................................................................................................................... 15

45° Miter Cutting........................................................................................................................................15

Custom Miter Cutting.................................................................................................................................16

Using Crown & Miter Pro..........................................................................................................................17

Increment................................................................................................................................................... 20

Saving Dimensions with List......................................................................................................................20

Entering Feet, Inches and Fractions............................................................................................................21

Largest Number Display.............................................................................................................................22

Entering Feet and Decimal Inches..............................................................................................................22

Largest Number Display.............................................................................................................................23

Entering Non-Standard Fractions...............................................................................................................23

Entering Millimeters.................................................................................................................................. 24

Largest Number Display.............................................................................................................................24

Entering Negative Numbers.......................................................................................................................24

Correcting Entry Errors..............................................................................................................................25

Home Routine after Impact........................................................................................................................26

4