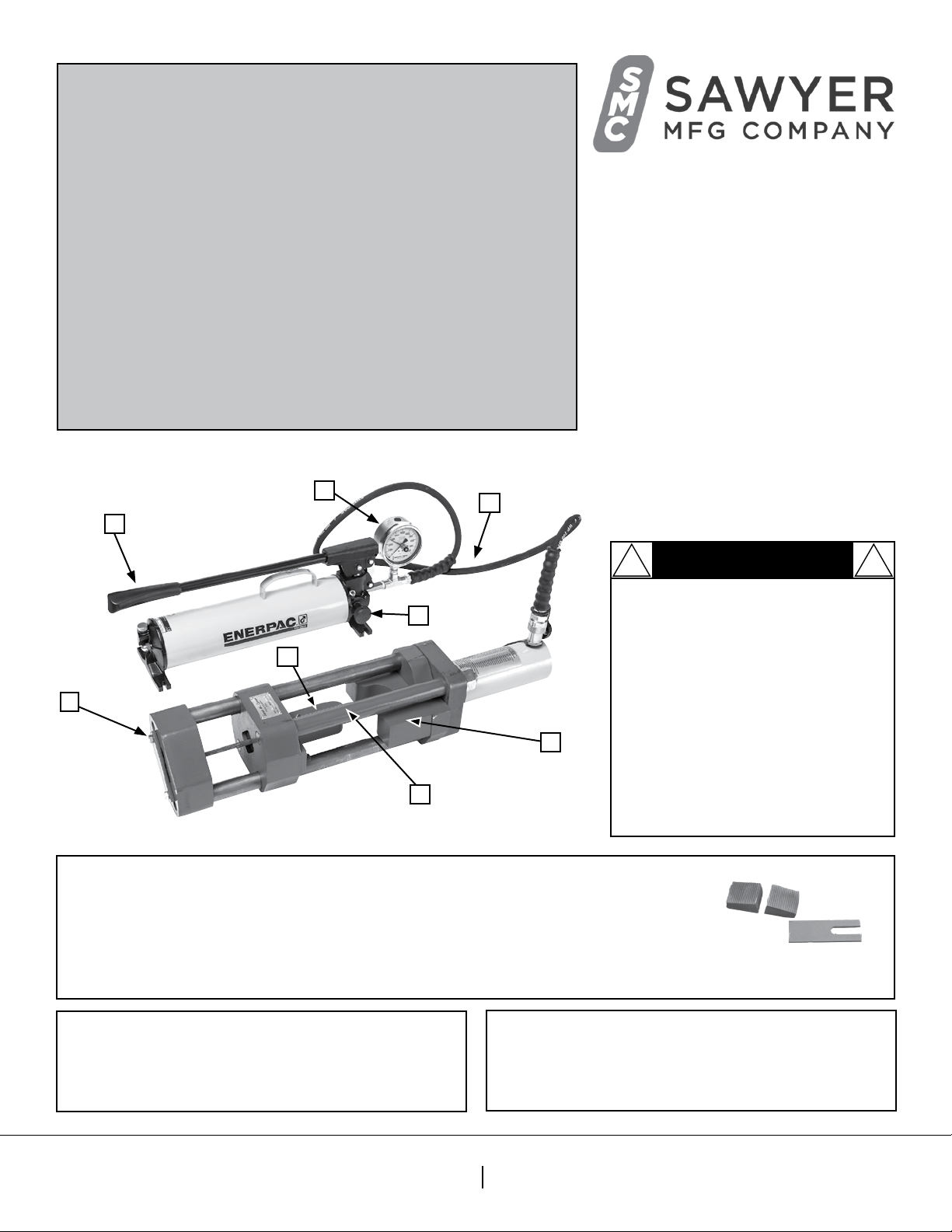

G

B

E

D

F

Sawyer Manufacturing Company

7799 S. Regency Dr., Tulsa, OK 74131 USA

F918.834.0318

info@sawyermfg.com

We appreciate your business!

Congratulaons on your new SAWYER product. We are proud to

have you as our customer and will strive to provide you with the best

service and reliability in the industry. This product is backed by our

extensive warranty and world-wide service network. To locate your

nearest distributor or service agency, please contact us at the phone

number and address listed on the boom of each page.

You are in good company!

Sawyer Manufacturing Company is the world leader in the design

and manufacture of pipeline and welding equipment and has been

since 1948. Sawyer equipment has become a standard in the industry

and connues to set the benchmark for quality and durability.

This user operaon manual has been made to instruct you for the best

use and operaon of your Sawyer product. Your sasfacon with our

products is our main goal. Please read this enre manual carefully,

nong all ps, notes and warnings. Safety always comes rst.

About Us

Warranty

All products manufactured by or for Sawyer Manufacturing Company are

guaranteed against defects due to faulty workmanship or materials for twelve

months from the date of purchase.

This guarantee is limited to the repair or replacement of any parts found to be

defecve, and no other liability–expressed, implied, or conngent–is assumed.

Record the following informaon for warranty purposes:

Where purchased:________________________________________________

Purchase date:___________________________________________________

Equipment Serial #:_______________________________________________

A. Hydraulic Relief Valve

B. ENERPAC Hydraulic Pump (526-5)

C. Hydraulic Hose Fing

D. Plunger

E. Die

F. Pressure Gauge (526-27)

G. Jaw Retainer (525AO-B)

H. Plunger “L” Bolt (A110B-C)

I. (4x) Jaws *not included*

J. (1) Jaws Tensioner *not included*

P 918.834.2550

sawyermfg.com

V1.2

CAUTION: Sawyer Manufacturing

Company oers a precise weld qualicaon

test for tensile strength and guided bend

operaons. The buildup of high pressure

inside the hydraulic guided bend and tensile

tesng machine can cause injury to personnel

and damage to equipment. To avoid a rapid

discharge, ensure that all pressure hoses are

connected and secure. When the hydraulic

pressure does not increase enough to bend

or break the sample, check the hydraulic uid

levels and add hydraulic uid as necessary.

Please refer to ENERPAC manual for

maintenance of ENERPAC pump.

! !

CAUTION

A

Guided Bend and

Tensile Tester

Manual

Models 273-25 & 273-55

For 25/55-Ton Applicaons

Parts Diagram

C

H