Contents

1.

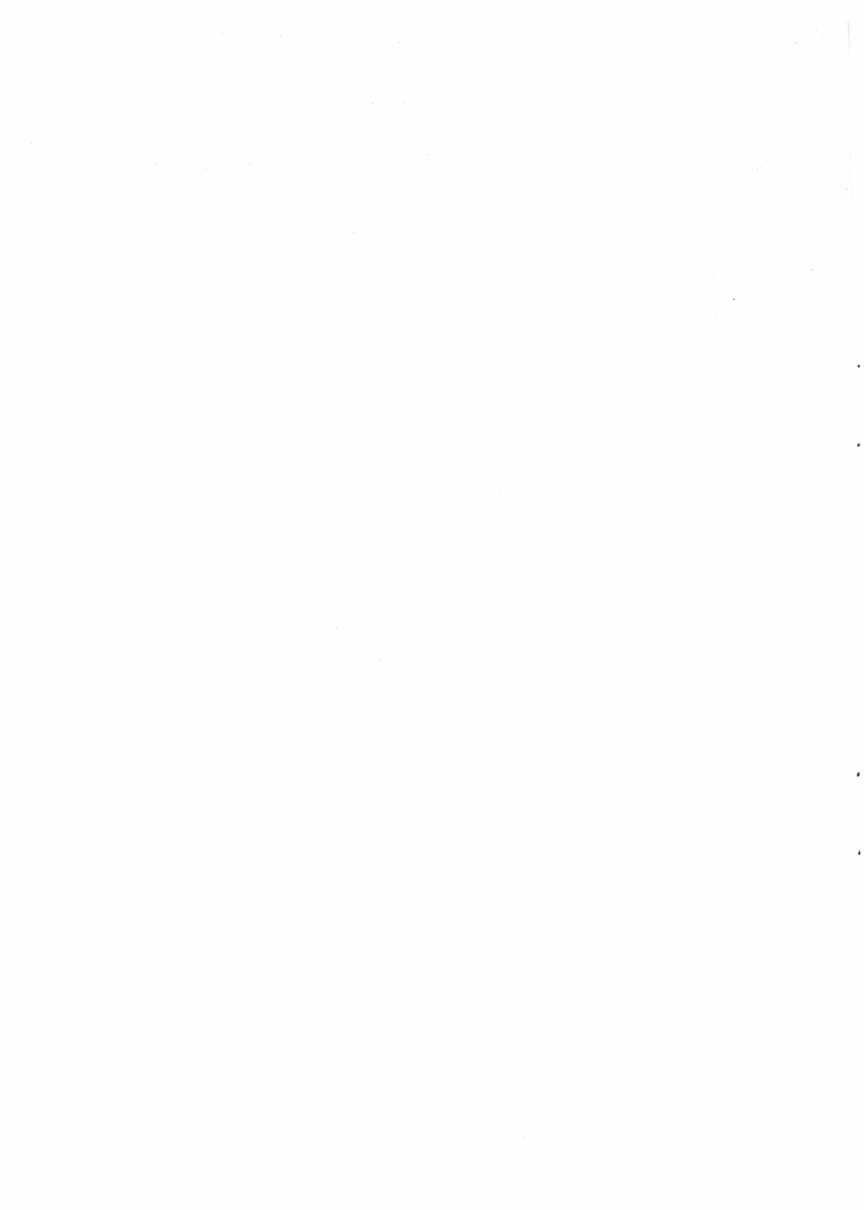

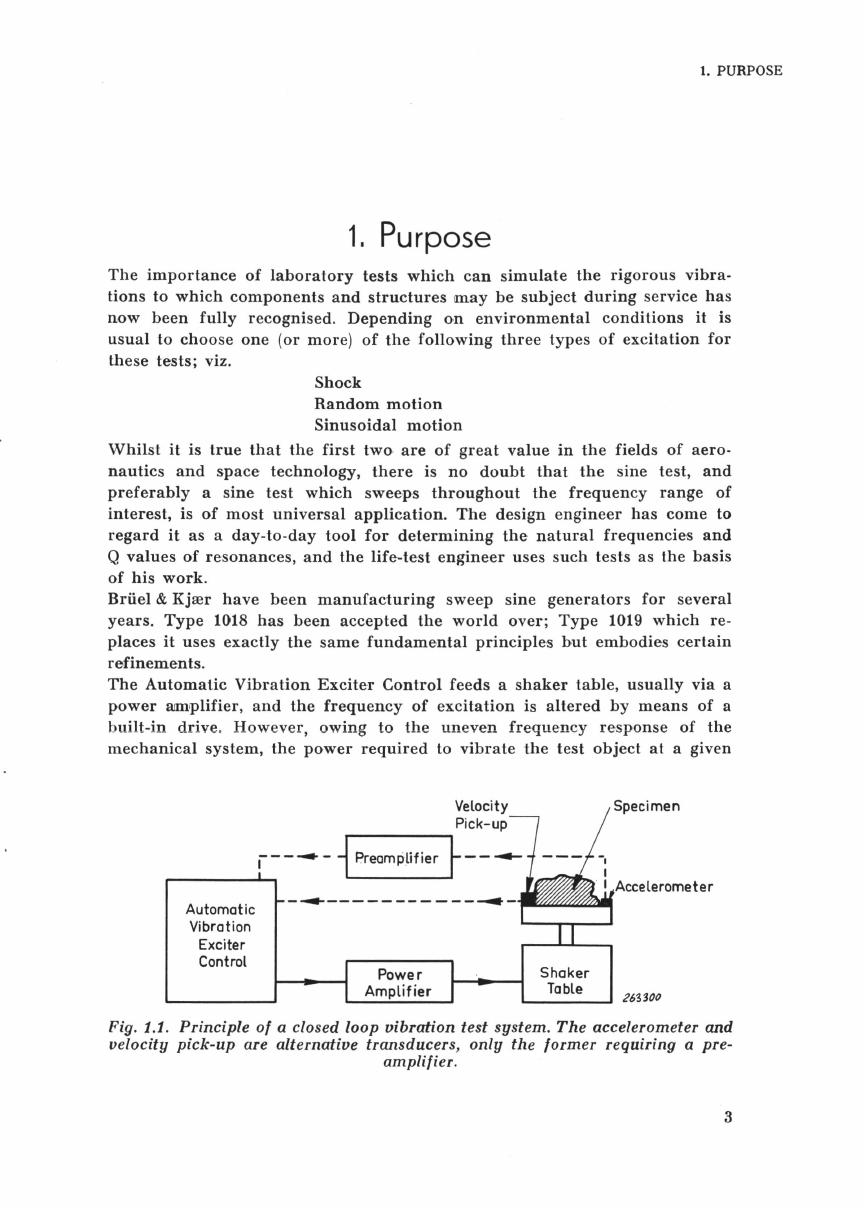

Purpose

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.

Description

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.

Oscillator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.

Automatic

Frequency

Scan

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.

Vibration

Derivation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.

Compressor

Arrangement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5.

Meter

Section

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.

Frequency

Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7.

Remote

Control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.

Parallel

Operation

of

Generators

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.

Control

l{nobs,

Terminals

etc.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

4.

Operation

as

Vibration

Meter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

4.1.

Setting

to

Mains

Voltage

......................................

21

4.2.

With

a

Velocity

Pick-up

......................................

21

4.3.

With

an

Accelerometer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.

Operation

as

Shaker

Control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.

Calibration

of

Frequency

Scale

................................

24

5.2.

Adjustment

of

Automatic

Frequency

Scanning

Range

............

24

5.3.

Uni-directional

Frequency

Scanning

............................

25

5.4.

Partial

Blocking

of

Frequency

Scale

Range

. . . . . . . . . . . . . . . . . . . . 26

5.5.

Setting

of

Scanning

Speed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6.

Setting

Regulation

Speed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.

7.

Possibilities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.8.

Setting

Auto

Cross-Over

Frequency

............................

30

5.9

Summary

of

Preparatory

Operations

............................

30

5.10.

Operation

Schemes

..........................................

31

6.

Operation

with

Level

Recorder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3b

6.1.

Possibilities

..................................................

35

6.2.

Synchronization

with

Level

Recorder

. . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.

Monitoring

Shaker

Table

Motion

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.

Plotting

System

Frequency

Response

. . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5.

Recording

Specimen

Vibration

................................

41

6.6.

Recording

Two

Quantities

Simultaneously

. . . . . . . . . . . . . . . . . . . . . . 42

7.

Remote

Control

Facilities

..........................................

44

7.1.

Start

and

Stop

of

Frequency

Scan

..............................

44

7.2.

Forward

and

Reverse

Frequency

Scan

..........................

44

7.3.

Stand

by

.....................................................

44

7.4.

Changing

Scanning

Speed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.

Master-Slave

System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1.

Principle

.....................................................

46

8.2.

Interconnections

..............................................

47

8.3.

Setting

Up

....................................................

48

8.4.

Adjusting

Individual

Vibrations

(Level

and

Phase)

. . . . . . . . . . . . . . 49

8.5.

Command

of

the

System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50